Join The Cornucopia Institute as we keep you informed via web updates and live tweets from the National Organic Standards Board (NOSB) meeting online.

We will be sharing the play by play of the meeting on April 28, 29, and 30 below and with our Twitter followers at #NOSB or by simply following our stream.

For background on issues up for discussion at the meeting, see:

- Cornucopia’s formal written comments.

- See Cornucopia’s formal written comments on the Native Ecosystems issue.

Read Cornucopia’s notes on the NOSB meeting beginning April 28. Stay tuned for reporting of the April 20 & 22 public comments.

Friday, April 30, 2021: NOSB Meeting

12 PM ET: Crops Subcommittee (CS), Proposals

Crops Subcommittee Rick Greenwood leads the discussion on crops issues.

Paper Pots – proposal

Steve Ela summarizes the comments on this proposal: Most people are in favor of us passing this. A number of technical comments:

- In terms defined, would like addition of words “typically in paper.” This is a very wide definition; there can be wholly synthetic papers on the market, as well.

- The listing is missing a requirement for continuous improvement, which would also possibly include commercial availability if a higher biobased content product was on the market. We have talked about this before. Difficult to get that wording in that was satisfactory to people. The Board on the whole does want this to be a continuous improvement and as more biobased products become available, I believe that listing will be reevaluated.

- One of the suggestions was using the seed standard – one of the issues is that papers themselves are synthetic and difficult to separate out biobased vs. non–biobased. Tough to do with some of those things because biobased does not necessarily indicated biodegradability and vice versa.

- Add language from last time regarding other 40% beyond the 60% – and we added some language on that. It is by weight.

- Another comment was to not allow virgin paper. Using recycled paper is very difficult because of the variance of the quality. There is a really a very little amount of virgin paper used in these pots.

- Some people asked that we provide standards by which biobased content would be evaluated by qualified personnel. By doing so, we created another set of comments regarding who those “qualified personnel” are – that’s a tough on. One person said they would like to see manufacturers listed by an MRO to provide a consistent product between certifiers.

- OMRI noted they would like the definition to include language from the…?

- We start to chase our tail a bit – in the original proposal we did not include any language on nutrients or pesticides – and we were asked to add language saying that these materials would have to be on the National List, and now people are asking for this wording to come out.

- Inclined to think that we are probably at about the right spot in making people uncomfortable on both sides of the aisle and thinking we can leave the wording up to the Program at this point.

- Finally, a number of people suggested listing changes in terms of the paragraph where they are listed. Good comments. I do not think they preclude us passing this, as it is up to the Program to write the rule. In our listing of these things, we are trying to help the program in saying where we thought they should be, but this is probably not a reason to not accept this proposal.

Stive Ela: Most comments were positive in favor of passing this. Question & comments?

Sue Baird: I appreciate all of the work on this. I think this needs to go forward.

Logan Petrey: Curious if this bleeds into plant tape?

Steve Ela: Intent is for it to cover this. We have not heard much from seed tape manufacturers, but we are thinking this listing would include those.

Wood Turner: I appreciate you acknowledging the issue on virgin paper. I continue to believe that the beauty of organic is that we are not contributing to other issues in the world, so I do get concerned that there is not enough innovation happening to move away from virgin paper, or that we are not limiting the source of the virgin paper, if it is used. This is an issue that is nagging at me.

Steve Ela: At least on manufacturer has testified that they are using a sustainably sourced paper. As a company, they are taking a stance on that. I cannot speak for other manufacturers. I agree with your comment. The scale does make a difference, but I’m hoping that manufacturers will take this seriously. Could not figure out how to word that in, but hoping this will get reviewed at the next sunset regarding the annotation needing updated in terms of ingredients and biobased content.

Amy Bruch: The next item that we are discussing – Bio-Based Mulch Film (BBMF) – has the built-in continuous improvement clause into it. It almost seems as if it is easier to do all of this all at once than to try to 5 years from now get a work agenda item to work on further annotations when hopefully in 1-2 years there will be improvements to hold folks to a higher standard. Is it worth it to include that in this clause now?

Steve Ela: We initially did include a biodegradability clause, and while some people want that noted, we had a number of people ask us to take it out. The wording becomes very difficult. We did have something similar toward the 100% biobased, but you can be 100% biobased and not be biodegradable. The definition of the commercial availability in this case of what items changed – cellulose content, biobased – we did not want to shoot ourselves in the foot of requiring some increase in something but having a worse product. On the BBMF, we are seeing some of those comments – 100% – what does that mean? Do you have to use it? What if there are better products that are 99%? As much as I don’t like leaving it to future Boards without having it written in, the devil in the details on this one. I hate to say it, but we are kicking the can down the road.

Kyla Smith: Thanks CS for your perseverance on this. Certifiers are grateful for the process that the Board and program went through to continue to allow these while we worked on this.

Steve Ela: In the cover sheet to the program, if it passes, I will note some of the concerns that were brought to us. The stakeholder input has been really valuable – want to thank them for all of their thoughts on things that we didn’t think about.

Amy Bruch: There was a commenter – certifying group – that had concerns and questions about annotating this in 205.2, since this is specifically more of a category and not a generic substance like most of 205.2. Overall, there was consensus in adding this to 205.601, but wanted to bring this concern up regarding 205.2.

Steve Ela: In talking with the program, the listing at 205.601 is for Crop Planting Aids, but we needed at definition of Crop Planting Aids. Some of these “where they go” issues can be addressed by the Program on how it makes sense in the regulations.

Kyla Smith: There is some precedent for this type of framework with a definition and placement – BBMF. ACA does have a continuous working group regarding materials. If there are questions, I think that group could take up getting collectively aligned with questions or interpretations of that.

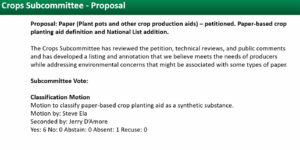

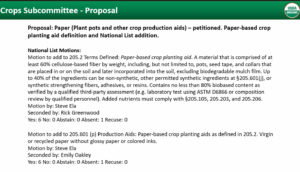

Classification Motion: Motion to classify paper-based crop planting aid as a synthetic substance.

- Vote: Yes – 14; No – 0; Absent – 0; Abstain – 0 . Motion passes.

Motion to add to 205.2 Terms Defined: Paper-based crop planting aid. A material that is comprised of at least 60% cellulose-based fiber by weight, including, but not limited to, pots, seed tape, and collars that are placed in or on the soil and later incorporated into the soil, excluding biodegradable mulch film. Up to 40% of the ingredients can be non-synthetic, other permitted synthetic ingredients at §205.601(j), or synthetic strengthening fibers, adhesives, or resins. Contains no less than 80% biobased content as verified by a qualified third-party assessment (e.g. laboratory test using ASTM D6866 or composition review by qualified personnel). Added nutrients must comply with §205.105, 205.203, and 205.206.

- Vote: Yes – 14; No – 0; Absent – 0; Abstain – 0. Motion passes.

Motion to add to 205.601 (p) Production Aids: Paper-based crop planting aids as defined in 205.2. Virgin or recycled paper without glossy paper or colored inks.

- Vote: Yes – 14; No – 0; Absent – 0; Abstain – 0. Motion passes.

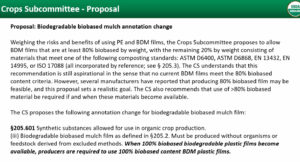

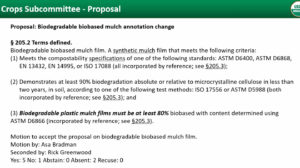

Biodegradable biobased mulch (BBMF) annotation change – 205.601

Asa Bradman: Issue is the use of BBMF – important to use the word “plastic” here, although some people do not like that – we are really talking about plastic films. Plastic can be made from petroleum sources, but also biobased sources, as well. To frame the issue: we have a current listing for BBMF – the 2 key requirements is that they not be produced with excluded methods and 2 – that they be 10% biobased. There is concern about traditional polyethylene (PE) films. Because there are no 100% biobased films available – plant-based carbon sources for the polymer of the film – and there are real philosophical concerns about the use of petroleum–based inputs for organic agriculture. There is a lot of support across many sectors to change the annotation regarding requirement of 100% biobased.

I think there is some real benefits to have an alternative to standard plastics. Is it reasonable to look at this as an alternative to plastic films? Is it reasonable to do a comparative risk assessment for this material against PE films? I think the answer is yes, but that is debatable. If we are doing a real risk assessment, then we need standards.

Comment summary by Asa Bradman:

Some folks commented that they hate using plastic mulch… We used to take our used plastic mulch to be recycled, but now we cannot. Plastic mulch is absolutely necessary for organic production; take it away and prices will soar and production will plummet.

A lot of depth for support for considering something that is less than 100% biobased. There is also support for the idea of an incremental approach. We made an aspiration change to allow 20% non-biobased. How did we come to that? As far as we know, there are not products out there that are 80% biobased and 20% petroleum based. In some ways, we borrowed that from the paper production aid rule. There is a certain logic to extend that to other materials. Some manufacturers said they could potentially achieve an 80% biobased product.

Other concerns about the language so far – I do not think we got all of the wording right, and I do not think we got the notion of continuous improvement right. I think we need more discussion on that – might send back to committee to try to get the wording right.

Verification is a challenge with the current wording. Suggestion that we look carefully at the bio–preferred products. There might be issues with having them made with excluded methods – but I think we need to look at that more closely.

I appreciate all of those who feel this material is not ready for primetime, and that we need more research that we are going to be introducing a petroleum material directly to the soil. I made the point that we already allow a component of petroleum to be used as a pest control in horticultural oils. One of the most heavily used pesticides. We already have a precedent that we are allowing petroleum to go into the soil in agricultural environments.

Comments that this was undoing the work of 2012 when the biobased standard was first made. This gets back to relying on precedent and when do we make a change? We are 9 years later, and circumstances have changed, and plastic use in organic ag has exploded, and that’s something we should all be thinking about. I think that some people are actually doing container growing by wrapping the soil in plastic. Even with PE films, there can be plastics that are left in the soil and probably microplastics that can be leaching in to the soil. When we talk about “plasticulture,” I think it is both potentially in container settings and soil settings. The term actually comes from our strawberry production systems where we are basically mounding the soil into plastic covered rows.

To emphasize, as laid out in the proposal, we cover both the range of reason to allow this and range not to allow this. There is a depth of support in many sectors. I do think we should consider sending this back to subcommittee to see if we could improve the language.

Brian Caldwell: I’m conflicted on this. I can see both sides with really strong arguments. What is tipping me in favor of this right now is that 2 different research groups that the mulches that are available now, some of them are 100% biodegradable. That really makes a big different for me. Over the years, I’ve spoken to several small-scale vegetable growers who have said they were not organic specifically because they could not use BBMF and refuse to use PE mulch.

Logan Petrey: You mentioned a lot of people talking about taking plastic to the landfills, and that gives a bad picture. You mentioned later that there are plastics left. I have actually had to rip up plastic, and it does not come up like a bed sheet, and there is a lot left in the field. I can see where using the traditional plastic can be limiting based on crop rotation and full utilization on the crop program. I am excited about this. I have seen it in use and was impressed with how quickly they went away.

Wood Turner: How do you reconcile these parallel paths between paper–based planting aids and BBMF and the very real reality that paper pots are also going to have similar components as approved that will be contributing similar synthetics to the soil in the same way that this annotation would in the case of mulches – how do you reconcile the feedback from the community on those two different materials? Should we be thinking about them in the same context, or are they two different things?

Asa Bradman: Part of me feels like if you support the paper pots rule as it is written, you have to support this, even though we are talking about a largely different scale. The Paper Pot rule leaves the 20% open to be nylon fibers, which are not biodegradable. A difference with the BBMF is that they have been designed so that bacteria can munch on them and they should decompose. This material should be less persistent and impactful than the paper pots. There seems to be a real need in the community for this material. It is hard to reconcile them. There are very thoughtful comments in the public comment regarding do we want these plastic mulches at all? I do agree that mulching with natural materials and that’s what I do in my garden. But the reality is that plastic has become entrenched in organic, and it seems to me that this product could be an alternative. I hope that they are 100% biodegradable and that we wouldn’t be introducing another source of microplastics into the environment, but we are already doing that.

Kyla Smith: As a certifier, I think I tend to hone in how we are going to enforce this. One commenter was talking about that. It is really the consistency of how the terms are being used. Right now, the term in 205.2 is “BBMF”, and then we start to introduce a new term with the word plastic in there. It is not because plastic is in there, but it is because it is now used inconsistently. I would encourage us to use to pick a term and go with it. If we want to replace BBMF with BBPlasticMF, then we need to do that and stick with it. Also, what I picked up about the percentage is the aspirational approach, and I understand trying to align that with the paper-based planting aids. When I was looking at the background information and all of the resources that we have to look at, I’ve noticed an uptake in that %. In the 2016 materials, I saw a 10-15% biobased, and now it is 60%, so there is that increase. However, it is still aspiration, and we will not be able to have products that meet that. We do not know when we will be able to have a viable product on the market. I think we should put a % in that could be achievable today or delist it. Then my last comment is about the term “availability.” Want to make it clear so that certifiers are able to enforce the annotation.

Asa Bradman: Definitely some issues with the wording that could need some fine-tuning in subcommittee. In terms of the issue of 80% rather than using currently available materials, I took my cue from the paper pots as a threshold. That might leave the frustration out there that we are still not allowing the product to be used, but as you have noted, there has been increase in the bio-based content. This sets a higher threshold, but I understand that it is potentially achievable.

Amy Bruch: The current situation with PE film is far from ideal. Is the alternative to PE film building a better film, or is it addressing how to improve the entire situation. The volume of the amount of plastic that is being used is pretty concerning, and that is how I can differentiate in my head paper pots vs. This material. The multiple use year after year is concerning. I’m concerned what it looks like after you have base-loaded system year after year. Most of the microbial activity in that top 4” of soil – if you want these plastics to degrade, it will have to be in those top 4”. I think more research needs to be done so that we get this right when we make this annotation change.

Asa Bradman: I hear you. We could look at the rule and if we had 90% biodegradation after two years, it wouldn’t be that hard to model plastic buildup in different soil types. That might be something to do to inform that discussion.

Carolyn Dimitri: My question comes from my training as an economist – what triggers farms to undertake specific materials? Do we have an understanding that farmers are actually going to switch to this? Or is this going to encourage people who are using something else to switch to this so that you are adding more plastic to the soil over the long-term to this product. I would like to understand how this would change farming practices? Are we going to prohibit plastic sheets from being put on farms?

Asa Bradman: I don’t know if this is a better system than PE film – I could vote either way or abstain. I do not think it is actually worse than PE films. There is support for this in the community across broad sectors. If I were voting about PE films right now, I might vote no to relisting, and that would be a huge disruption to the market. I wish we were using plasticized materials – I think it is a bit of a stain on organic. It is used across all sectors – big and small, corporate and not corporate, Real Organic Project (ROP) or not – it is everywhere. I think there are real philosophical issues with this one.

Wood Turner: I fundamentally agree that organic should be a real contributor to a more circular economy. It occurs to me when listening to this conversation, we have fairly tightly defined the research priority to this. What we are really talking about here, it shouldn’t be that narrow. Frankly, we need to understand ore clearly the life-cycle impact of plastics on soil – period – the end. It should be about the true life-cycle implications of the use of plastics. I am going to argue from a research priorities position that we expand the view of what we are really asking for in the way of research to go well beyond BBMF.

Kyla Smith: Was going to try to answer Carolyn. More from a not sure about those that are currently using plastic mulch and if they would make that switch – probably some would and some wouldn’t. I do think we will get more operations go to certified organic if they are allowed to use these materials. I guess that’s a philosophical question of whether or not we want those operations under the tent.

Mindee Jeffrey: I am emotional about this issue. At Good Earth about 15 years ago, we did a big push on how people could stop choosing plastic in the store. People want to be real contributors to positive environmental change. Organic leaving microplastics in the soil, I cannot get over it. I do not enjoy disagreeing with Asa. I could be comfortable sending this back to subcommittee and see if more agreement comes from stakeholders after we do that work, but I’m not there yet. Looking at the ethos of organic and the scale at which we have succeeded means to me that I do not have to compromise more on industrial scale.

Asa Bradman: I appreciate that. For me, it is the idea of a petroleum product. But there is this comparative risk assessment idea – plastic use is exploding and increasing overall – look at strawberries in CA, other berries, I’ve seen it in tomatoes – my understanding that plastic use in organic is exploding, and those are introducing microplastics into the soil and environment in general. Is this a better system? If it fully decomposes, we would not be introducing microplastics into the soil.

Carolyn Dimitri: Following Mindee’s line of argument, I think another important research question is to try to understand what are the implications for overall plastic use for farmers if this type of product was allowed. More of a social science research.

Nate Powell-Palm: I hear Mindee clearly and the idea of strawberry growers innovating clam shells with papers. I think that we can figure things out in organic, and sending this back to subcommittee is the way to go. This is important enough.

Steve Ela: I was the descending vote out of subcommittee not because I disagree with Asa at all. I am very much against PE mulch – it drives me crazy – and I really struggle with what the next step is. I am not convinced at this point that the BBMF is truly biodegradable in most systems. I’m glad Asa decided to bring a proposal to this meeting to frame the issue and really helps people to respond to things and try to narrow it down.

Motion made that we go back to subcommittee: Mindee Jeffery, seconded by Nate Powell-Palm.

- Vote: Yes – 14; No – 0; Absent – 0; Abstain – 0 . Motion passes.

1:20 PM ET: Crops Subcommittee (CS), Sunset Review

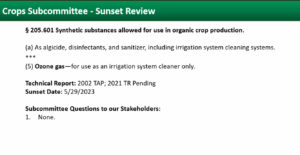

Ozone gas

Rick Greenwood: Ozone works by oxidizing plant tissues similar to chlorine, used as a antimicrobial agent. Overwhelming support in comments. Advantage over chlorine – no residue left. Used in municipal waters. Relationship with atmosphere worries people, but used in a closed system so no off gassing. Potential for injury in use, but doesn’t seem to be a problem because of the way it’s used. No comments against it.

Kyla Smith: Often used as a fruit sanitizer.

Rick Greenwood: Seems to be fairly effective when used in closed systems. Didn’t see anything in particular about fruit in comments.

Steve Ela: Have heard of it used in irrigation lines, but can’t speak personally. It would be an important use in cases where water was directly applied. It used in dump tanks in packing sheds sometimes.

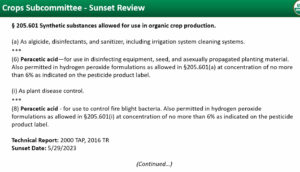

Paracetic acid

Wood Turner: There’s a lot of use in the community. Favored by many because it is one of the most effective materials in disinfectants that does not involve chlorine. Across the community, extraordinary amount of support. Falls in conversation about sanitizers and what provides the most efficacy. The use in a crop setting is different in a facility because there’s not the same considerations for outdoors. Most of the international community supports it. Very widely used. Some irritation when substance is mis–used – but not a major concern in the community. Some concerns around the source, but overwhelming support overall. Running list of stakeholders who want to see it listed.

No questions.

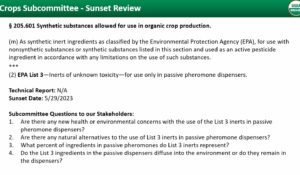

EPA List 3 – inerts of unknown toxicity

Note: allowed use is only in passive pheromone dispensers.

Steve Ela: List 3’s play an important role concerning pests that effect many crops. Used in many applications – apples and peaches. Only way to control organically in these cases. All arguments made for list 4 can be made for list 3. Not applied to the fruit, contained in the dispensers. Lower amounts are used and not directly applied. Biggest thing is they are on a defunct list – there is lots of comments from stakeholders. One was recommended to be taken off the list – number of stakeholders commented that this was not a proper listing. We can encourage or ask in stronger language that these have to be dealt with, they can be dealt with list 4 ingredients. At this point there are no alternatives. Do passive dispensers diffuse in the environment? They do not because they are much heavier. If removed, would cause significant disruption in the industry. Very widely used in organic and conventional. Biggest recommendation is to change classification, individually instead of in a large group.

Asa Bradman: A little frustration that we have not dealt with list 3 and 4 issues, when we could have dealt with them a long time ago. Could have dealt with them individually instead of in lists. Can avoid drama in the future.

Steve Ela: That comment is shared widely by stakeholders. Jenny said they have released notice of rulemaking to create movement on the issue. To stakeholders: I hope that solutions are put into those comments and not just concerns. It’s up to the stakeholders to give ideas to the program. If not, will continue to be a quandary.

Jenny Tucker: Wanted to clarify that I have committed to moving this forward. Have drafted a notice for rulemaking but it has not been published. This is a process that worked – community came together on comments and agreed that it was important. System works for these priorities.

Steve Ela: I appreciate you letting us know it is in process. Recommend to stakeholders they provide suggestions in comments.

Kyla Smith: A question for Jenny based on her comments. Clarification on whether the rulemaking is on the agenda for spring.

Jenny Tucker: Unsure. Definitely on the fall agenda. Once we write it it has to go through clearance. IT is way further in the pipeline compared to April. It is on a list called the critical priorities lists. No specified exact deadline. We’ve made progress since committing in the spring.

Rick Greenwood: One comment. Part that bothers me the most is where we have the comments where it says: inerts of unknown toxicity. It is not a good title to have. We’re so specific on some things, but not on others.

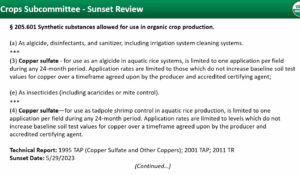

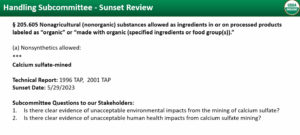

Copper sulfate

Copper Sulfate 205.601(a)(3) – For use as an algicide in aquatic rice systems, is limited to one application per field during any 24-month period. Application rates are limited to those which do not increase baseline soil test values for copper over a timeframe agreed upon by the producer and accredited certifying agent.

Copper Sulfate 205.601(e)(4) – For use as tadpole shrimp control in aquatic rice production, is limited to one application per field during any 24-month period. Application rates are limited to levels which do not increase baseline soil test values for copper over a timeframe agreed upon by the producer and accredited certifying agent.

205.601(i)(3) – (3) Copper sulfate—Substance must be used in a manner that minimizes accumulation of copper in the soil.

Jerry D’Amore: Made by treating copper metal with metal sulphuric acid. In comments several were opposed, given lengthy comments. Most of the comments came from rice producers. Most opposed were focused on current annotation and our process. Needs to be more specific. Need to continuously improve.

Not response to second question indicating that it is a heavy list. I believe not relisting copper sulphate would be damaging to organic rice producers. Recommend relisting copper sulphate. Through this process was very heartened by the tenor of the stakeholders. Neither were entrenched in their position.

Brain Caldwell: The previous slide I saw on my computer screen was a bit different than what I have in my notebook. There is a 3(e) listing in there that I do not think is in my notebook – is that separate than the use in rice production? Since it can be used as both algicide and tadpole shrimp – is that two uses?

Jerry D’Amore: That is part of the feedback that we are getting – that questions like that have not been addressed – and it may allow two applications in two years. That needs to be addressed. I’m seeing 3(e) on this slide for the first time, and I’m not prepared to address that.

Brian Caldwell: I’m with you on that one. Copper Sulfate was part of a really old miticide from way back. I do not know so much about how rice is grown in CA, I assume that the field has to be dry for the rice to be harvested. Is that process where the water seeps into the soil or where a gate is opened and the water runs off? If it is the second, then a lot of copper sulfate could be run off the field into some waterway somewhere.

Jerry D’Amore: There is significant rice production in the US and limited in Canada. I do not know how the field is dried.

Steve Ela: There is a little misunderstanding – in this listing, the second is listed as an insecticide, but for use with tadpole shrimp control. You do not have to address the mite usage.

Brian Caldwell: I’m thinking that the water issue could be addressed by the committee.

Nate Powell-Palm: Jerry, could you speak a bit about the state of continuous improvement for rice farmers. It seems that this material is being used somewhat sparingly, but that rice farmers are on the hunt for a material that could be used in its place. What do you think the state of the industry is, and could we work towards a reasonable path toward de-listing in the next five years?

Jerry D’Amore: I see a community in rice farmers who have been and is looking for alternative solutions. With that said, we have given them this tool since 2011, and once a tool is given, it eventually becomes essential. I would say at this point it is an essential tool for their ability to be in the organic world. I would further say that the notion that we need to show forward process to finding a way to take that substance out of the toolbox is where we are all headed. If I were around in five years, I would be disappointed to see ourselves asking the same questions.

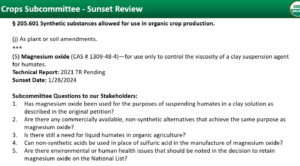

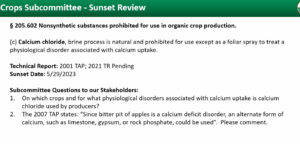

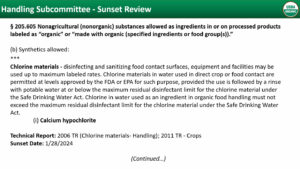

Chlorine materials

Includes: i) Calcium hypochlorite. (ii) Chlorine dioxide. (iii) Hypochlorous acid – generated from electrolyzed water. (iv) Sodium hypochlorite 205.601(a)(2) – For pre-harvest use, residual chlorine levels in the water in direct crop contact or as water from cleaning irrigation systems applied to soil must not exceed the maximum residual disinfectant limit under the Safe Drinking Water Act, except that chlorine products may be used in edible sprout production according to EPA label directions.

Wood Turner: We have talked about these in Handling and Livestock. I believe a comprehensive approach at how we look at sanitizers needs to be contemplated as we move forward. Not a lot more to say about these materials. I think we talked them through quite thoroughly already. We all know that chlorine materials have some human health concerns, concerns about aquatic systems and habitat. There are concerns that we all know and are trying to navigate. The lingering issue for me is whether or not the use of chlorine materials in crops systems for cleaning equipment or irrigation lines or the like is fundamentally the same FSMA consideration that cleaning surfaces in a facility or in livestock facility and whether or not there is a difficult category of uses on crops. I’d like to hear from stakeholders on that.

We’ve also had this very robust conversation about plastic in organic. We all share the concern that petroleum-based product us is sub-optimal, and one might argue the same with chlorine material. I will also acknowledge that Emily Oakley helped to draft some of the framework on how we look at sanitizing materials in general, but the community did not like that I included it in the published materials that went out. I wanted to try to use it as a way to create some kind of continuity between the sanitizer panel that we had in the fall and how we are looking at these materials and potentially a comprehensive review of sanitizers.

Asa Bradman: Thank you, Wood, for your work on this and our discussions on chlorine materials.

Steve Ela: We personally do not use it because we pick dry, but for those folks that have to hydrate because they pick things that are very perishable, I think they would have to use it. There is also a scale issue with some of these sanitizers – larger facilities may be able to use a more diverse group of sanitizers, but smaller groups may have lack of access to different things.

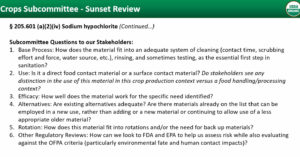

Magnesium oxide

Amy Bruch: Wide range of uses outside of this particular use. This is the first sunset review for this product since it was added to the national list. International list – no references for sue in crop production. Received a handful of stakeholder comments generally in favor. One comment suggested included a time-frame for future review. 5 questions and general answers from commenters:

- It currently is used.

- Alternatives: There are a few alternatives, but they’re not commercially available or do not meet physical specs

- Humates can support biological life in the soil.

- Non-synthetic alternatives? No addressed in comments. Will need to be re–evaluated. Perhaps TR will address this, TR has been requested.

- Mainly in the manufacturing process. Carbon dioxide is released. If not available, humates would need to be released in dry form causing exposure to dust.

No questions form the Board.

Calcium chloride

Logan Petrey: A lot of support from commenters. Used in fruits, vegetables. Blossom rot, bitter pit, cabbage issues, and others. Some are not seen until post-harvest issues which can lead to costly rejections. Second question was about alternatives – no matter how much calcium you can have in the soil, it does not prevent deficiencies. Calcium is a nutrient that is taken up through a transportation rate in plants, and no matter how much you add to the soil, it does not always amend the problem. Once it is in the plant, it is considered immobile. A lot of support from commenters. Widely used. Do not see any negatives. People support the relisting with the annotation.

No questions or comments from the Board.

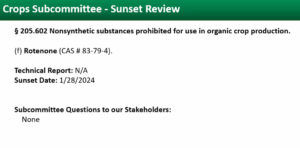

Rotenone

Rick Greenwood: This is a potent non-synthetic botanical. It is only registered as a piscicide (fish killer)and not available for purchase in the US. Banned in EU and United Kingdom. We had a few comments on it – keep it as a prohibited substance. I do not think there is much else to say about it. It is for sale in some places around the world, so we want to keep it on 602 to not allow it from coming into the country.

No questions or comments from the Board.

2:15 PM ET: Lunch Break

3:00 PM ET: Crops Subcommitte, Petitions / Discussion Documents

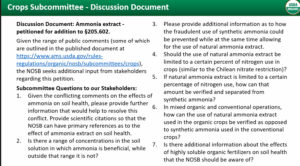

Ammonia Extract—petitioned for addition to 7 CFR § 205.602

Steve Ela: Nitrogen is one of the things that is constantly an issue as a grower. It’s a complicated topic. The number of thoughtful comments were appreciated. Asked for references; our stakeholders came through (not read all scientific references yet, but will).

Break down presentation (covers 6 things based on questions asked to stakeholders):

- Professionalism: Not as much professionalism from stakeholders in this topic. “Obvious commercial bias” references by commenters. Might raise questions about the NOSB. Say to stakeholders: offensive to get comments like this; these comments are not appropriate. The NOSB looks at each petition as written; we take all of them seriously.

- Definition of “ammonia extracts”: Does the petition definition fit? We will have struggle coming up with a definition. [Reads petition definition of “ammonia extracts”]. The definition in the petition raised concerns form many stakeholders, most saying definition is too broad; valid criticism. Many ammonia products have been approved for years and we might not want to include those products in the definition. TR/stakeholders have identified two different processes in creating ammonia extracts: ammonia stripping and ammonia concentration (take original material and removes water). When we had oral commentors talking about their products still including soluble organic compounds [carbon] they were speaking about concentration method. Stripping methods take ammonia out of the product so that it is pure ammonia. One includes carbon and one does not—we have to consider how widely we want to cast the net. We may want to limit a certain level of ammonia. OMRI has noticed product review applications increased recently for high nitrogen fertilizers; variations on both types of creation methods. Another note: non–synthetic fertilizers that test above 3% are considered to be higher risk of mis-use in soil contamination; use must be part of OSP. These should not be used in isolation, requirement for soil building/natural resources still needs to be complied with. The scope of the petition does not cover other fertilizers that also contain ammonia (but still contain organic matter, ex. Fish emulsion).

- Soil health and biodiversity: A lot of the comments addressed this issue. Always have to go back to OFPA that gives us the seven criteria we use to evaluate substances. Petition said that if we did not prohibit these substances, we would be going against OFPA. Plants already uptake nitrogen in ammonia/ammonium forms. If we apply manures the process of mineralization occurs throughout the year, so there are some comments that nitrogen can be lost when plants are not using it. Effect of bio-based fertilizers was more evident in low-biological activity than in high-biological activity. Comments promoting ammonia extracts: capture allows precision in apply to fields, limits volatilizing to atmosphere. Reduces chances of buildup of P in soil profile (which can occur from using manures). Potential groundwater contamination from manures and other org N products are applied when the crop does not demand it. Comes down to carbon-nitrogen rations; lower C levels than N there will be reduction of soil C. Materials that are higher in C will increase characteristics related to soil organic matter. Comments also note/remind us that: Prohibition of synthetic high nitrogen fertilizers was a primary motivator of the organic motivator. Products that mimic synthetic nitrogen fertilizers should be considered the same way as inherently incompatible to organic principles. Note that some of these fertilizers are of higher solubility, they are counter to fundamental organic principles. “Law of return” where residues are returned to the soil through tilling, mulching, etc. Most organic practices work on recycling materials into the soil; special attention should be given to SOM. What supports nutrient cycling? Manufacturers comment that these fertilizers are not meant to be the sole source of fertility. Note that: comment that tried to do meta-analysis from these types of fertilizers: crop-rotation, legumes, and other organic inputs all have their own issues that affect soil health and it’s difficult to make over-arching statement for these kinds of products. Previous management history also affects soil organic matter. That’ a high-level summary of soil health and biodiversity issues.

- Yields: Noted by commenters that these extracts can help increase yields to help organic compete in the market. Conversely in the public comments: citation to organic farming trials by Rodale—no statistical difference in yield between conventional and organic. That to me counters argument that there is a need for extracts to increase yields. Long-term consequences of conventional practices harms soil, and exacerbates ongoing environmental risk factors. Organic yields have kept up with conventional yields. Steve Ela comments about organic peaches.

- International recognition: International consumers: sodium nitrate is an issue with Canada; they do not accept crops treated with it! Issue with USA-CA equivalency agreement; needs to be paid attention to. Example: organic tomato growers, may have difficulty exporting bc of use of small amount of sodium nitrate.

- Highly soluble fertilizer sources: General comments note that non-synthetic mimic synthetic fertilizers and have been prohibited in the past. One past NOSB voted to completely prohibit; previously limited to no more than 20% applied. So there is some precedent to limit usage. Carbon value of original source material not contained in product those products have also been prohibited; part of the bio char debate for example. May not comply 2004 NOSB recommendation. Alternatives: there are some fertilizers with over 10% nitrogen content. Commentors note that it is time to regulate highly soluble N; it’s appropriate to limit them. Ammonia extracts are not unique that allow growers to feed their crops w/o feeding the soil. Some commentors wanted all fertilizers that don’t feed the soil to be regulated; organic farmers should be required to add carbon back into the soil.

Steve Ela: Finally, hate to create situation where grower could use 20% of each different highly soluble source (ex. Sodium nitrate, fish, etc.) and put certifier in the difficult position of writing a noncompliance where this is not clear. Tracking compliance in the face of uncertainty is a concern.

Curious to hear from Amy and Logan as other growers. On our farm we try our best to get fertility form vegetative sources with manures as a small addition. Some commentors noted that manures were the main source of N, and that’s why these extracts would be useful (to avoid P build-up).

Amy Bruch: On my farm (row crop, pulses, oil seeds, etc.) we look at fertility 3-5 yr basis. Can’t rely on just manure-based system because of accumulation of P and calcium. Complementary rotations. Robust crop rotations help with fertility, especially with corn, and help with weed management. Programs/rotations are multi-faceted. Total system approach: growing our N is important, helps create biodiversity, increases soil organic matter (SOM) which helps with future N needs. The legumes are good at generating N. Apply feather meal; use some biological activators (humic acid). We take annual soil samples, part of water districts where we have to report N levels to water board. We have Great resources that helps us analyze our soils short-and-long-term. Manure application is not a one-turn benefit, it’s multi-year.

Logan Petrey: I am in the southeast. We have a lot of rain and sandy soil, so we run into leaching issues of N, sulphur, potassium, etc. It makes managing fertility Hard; we often do our crops in the winter to avoid pests. The cold prevents manure-based fertilizers from breaking down, preventing N release. So soluble N are not ideal in an organic system it helps prevent crop failure. Fertility is the #1 tool to fight against insects and foliar pests. Once plant is looking healthy, it’s more robust against disease. Although our program is not built around soluble N fertilizers, we do use them when we need them. It does not reduce our use of crop rotation, which is extensive; it does not limit our use of natural fertilizers. We use a lot of chicken litter (broiler side preferred to avoid phosphorus buildup). Cover crops (mostly in summer) are also used to combat fertility issues. No grower in the area can use only cover crops because of the amount of leaching we get, in part due to planting season (which is during hurricane season). We can’t just do pre-plant application, then do 2-3 side-dressings per crop. Manures are diff to get the amount of N needed; feather meals have high N availability. 2-3 week release of N with each pre-application. But when the crop is 2-3 weeks from harvest you side-dress when needed (to prevent damping off issues). There is loss with natural fertilizer also. Agree that limits on extracts are fine because I prefer to use natural fertilizers. But the soluble fertilizers are needed in this area to maintain yield. Lifetime of FL experience.

Steve Ela: Would like to come to a proposal next fall. Feedback from rest of Board?

Wood Turner: Trying to wrap my head around this. One question: not comfortable that there is a clear enough definition of what the material is? This petition is a blanket; not sure we are capturing nuance we are hearing in comments and Board. Something lacking that could benefit from a clearer definition.

Steve Ela: we didn’t get a lot of response on the definition issue. Like with BBMF and paper pots, the nuances are important. My bias would be to write a definition that is conservative; we don’t want to take out products that have long been a staple of organic growers’ toolbox. The working in the petition definition might be overly broad. Concentration versus stripping: tend to lean toward preventing stripping because it’s much more similar to conventional synthetics. That’s where I would start; will talk to more people over summer.

Kyla Smith: Yes, we need to hone in on definition.

Steve Ela: As certifier, if someone is using highly sol fertilizer, and you are looking at farm system plan how do you suss out the use of a highly sol fertilizer versus something else required in a soil system?

Kyla Smith: I don’t have the regulations memorized.

Mindee Jeffery: Not an ammonia expert; mulling over highly soluble issue. First reaction we have to prohibit this. If we can get a clear definition I think it would support innovation, especially where we can support limited need of this product. Great definitions and narrow annotation would be great. Is that within the scope of the petition re-write?

Steve Ela: Yes, we’ve done that in other cases. We can say: “We agree with petition, EXCEPT…” is possible.

Amy Bruch: Looking at conversation on BBMF; seems to be need for extracts that are using plastic mulches. Comprehensive systems approach is hard to do with plastic laying on soil. Whole organic approach—we need to step back and look at dominoes of what you’re doing. That concerns me (not having access to soil). As Logan mentioned, we also do split applications. It’s hard to get multi-nutritional sources to your plants.

Steve Ela: Healthy soil means our trees get to eat the smorgasbord.

Carolyn Dimitri: Last two comment follow up: I’m an economist, not an agronomist or farmer. My default is to the organic ethos. It would be helpful: is there a way to have 3 sentences in English that would help consumers understand where we end up on this. Need to distill this so that someone can feel comfortable. That’s my request; I don’t have an opinion.

Steve Ela: We do have to frame things correctly (ex. Organic pet food).

Nate Powell-Palm: I don’t have a lot of experience in southeast, more so CA to PA. When speaking to organic Agriculture’s contribution to climate change; we don’t use ammonia, organic is not super input-heavy. Prices for grains flux a lot. Market stability is due to needing to rotate crops (people can’t grow corn every year). Worst fear is that someone certifier shops and just raises corn on corn because its do-able (with ammonia). Ammonia extracts flies in face of organic ethos. Think that regulating it really hopeful, because of isotope testing. We can make sure people are not just using conventional ammonia. There is an organic place to integrate livestock; don’t have them divorced, ending manure into waterways, and crops having a deficit of soil micro–bioactivity. Think organic crops need livestock nearby, or getting manure onto their ground. Spoke to farmers who don’t have livestock and they do lots of crop rotation (rye for seed, hay, etc.) because they can’t push their system just to maximize corn. Good to communicate to public about organic contribution to climate change.

Kyla Smith: Add 205.203 is the soil fertility standard; we would look at input use and that practice standard as well [as certifier]. Unless material has specific annotation, we don’t necessarily look at inputs outside the wider context of use. It’s not a hierarchical regulation like in other areas of the regulation.

Steve Ela: Fraud – Sample at manufacturer and at farm have to be consistent. You can’t just look at the soil, need to look backwards. Grower oversight red flags is important. Fraud may not be as big of an issue as overall fraud is.

Kim Bruch: OMRI written comments did mention that isotope ratio testing as they had previously commented that it’s not reliable. Something to note. Organic space has debates around fraud in one context or another. How do you manage other than a mass balance? Need to consider as we look at this more.

Steve Ela: Should have probably spent more time on fraud in future write-ups I will. As we work to write a proposal CS will reach out to others on the Board for input.

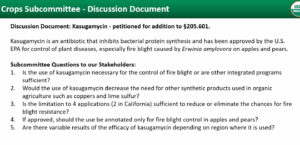

Kasugamycin—petitioned for use as an approved active ingredient in organic crop production at 7 CFR § 205.601.

Rick Greenwood: A long time clinical microbiologist and lab director – the thing I have seen in microbiology is antimicrobial resistance. Nothing is really sadder than isolating a person that has tuberculosis and finding that they have a very resistant form of tuberculosis. The other is MRSA – incredibly resistant microorganism. The reason these are around is the over use of antibiotics – not only in humans, but also in the whole animal industry. Microbiologists have recognized it, and the bacteria and microbes have recognized it even faster.

This is another aminoglycoside they want to use for fire blight. Comments from growers is that they want another tool in the toolbox. The public and many of the other groups – 250 comments – keep antibiotics out of organic. I think it is a pretty clear message that people do not want them there. Some of the concerns we have – came up in the TR – resistance gets built to these very quickly. Other issue is that when it gets sprayed on trees, animals can get to it.

There are cultural methods to make it more difficult for fire blight – you can control it – it is much more difficult, and there are regional differences. Some areas, not much of a problem. When it has been used, it has developed even in Japan starting in 1965, resistance developed very quickly and could not be used. Also, in Florida on tomatoes. There is history for these things.

Happy to talk about this. I would say our stakeholders really do not want us to have something else come into the production area as an antibiotic. The NOP and NOSB identified several reasons to stop the use of streptomycin and in 2014 stated that the expectation is that antibiotics not be used in organic production. I feel for the growers, but I think it would be the wrong message to send to our consumers. CA has allowed kasugamycin with an application plan, but I think it won’t be long until we see resistance.

Brian Caldwell: As an apple grower, I think farmers have to realize, without our customers, our crops are pretty worthless. There is overwhelming sentiment against adding antibiotics in our production systems. There was quite a fight in 2014 to take antibiotics out of apple and pear production. I’ve been a grower for over 40 years – we do see fire blight, but we do use cultural practices. Most of our varieties have lesser susceptibility, we use resistant root stock, and we do not push our tress – and that’s a big one. A big part of the problem is pushing for production. The market can be strong for all varieties. Less intensive planting systems with root stocks that have resistance – farmers don’t want to do that – but it can be done. And taking it easy on the fertility. That is pretty much my message. We really have to keep in mind that the consumer is the one who buys our products, pays a premium, and supports us.

Sue Baird: In poultry, you have to rotate antibiotics because they build up resistance. If we allow antibiotics back into organic production, they are going to build up resistance. I am thinking about the perception that people are being bombarded with now – that we are diluting the organic standards. If we approve adding antibiotics back into the National List, I think we are going to get slammed hard.

Steve Ela: As an organic grower, fire flight is a big issue for us in pears and susceptible varieties. It’s not a big deal until it is systemic. I think climate change has made it worse. It is really a combination of water and temperature. Water and cool – bacteria won’t expand. Warm and dry – bacteria won’t move. We used streptomycin when it was still on the list. Really useful because you can put it on up to 24 hours of having an infection even – would kick back and help with issues. In Colorado we tended not to use it much, so we did not have resistance. Once those were taken off the list, the next years there were a couple of products released that are more effective. The method now is a systems approach that does involved copper and lime sulfur early in the season. A lot of organic growers use lime sulfur for thinning. The problem now is that we are using a yeast product, but if you are using lime sulfur for thinning, it would kill the yeast, so you have to be very precise in your timing of application. Most of our varieties are resistant, although we do grow some that aren’t because consumers demand them. We have not lost a lot of trees to fire blight, but we have reduced our canopy by 60% in some. I argued against the removal of antibiotics from the National List, but with this material, I would hate to change the precedent set by the Board. I think the resistance is real. My stakeholders would say to absolutely approve this, but I think we also have to vote our conscience and gut feeling. I am going to have a tough time with this one. I’ve never abstained on a vote. This could be one. Leaning that it isn’t acceptable.

Mindee Jeffrey: Not in favor of allowing antibiotics in organic. I think it really behooves us as a community to provide more context to consumers. We have a really beautiful form of democracy, and I think we try to help consumers understand that we review all petitions equally. We will always evaluate each petition neutrally, and then ask consumers to support us.

No other comments from Board members.

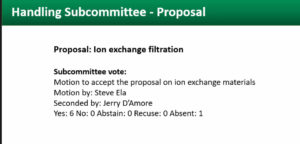

4:23 PM ET: Deferred Votes

Ion exchange filtration

Steve Ela: Before we vote, I would like to open back up for a brief comment period from the Board to see if there is anything else that needs to be said before we move to the vote.

Brian Caldwell: I do have some information that was new to me. I was concerned yesterday in our discussion that styrene is considered a probably carcinogen, but polystyrene is not, which is what is listed as one of the materials. And polystyrene sulfonate, which is one of the resin materials, is actually used as a human medicine, and it is 100% excreted. Even if this would get into some products, it sounds like it is not harmful. That put my mind to rest on that issue. I would still like to see this go back to the committee. I think we could vote separately on resin materials. I would also like to hear the group come to some kind of agreement on what it means that the process causes a chemical change in the organic product and what that means in terms of its status. If we do vote and decided not to send it back to subcommittee, I will vote in favor of it, as I think it is more important that the NOP gets some guidance from the NOSB than not.

Asa Bradman makes a motion to send back to subcommittee. Carolyn Dimitri: Seconded. Motion to send back to subcommittee.

- Vote: Yes – 4 – Wood, Asa, Amy, Brian. No – 10 – Rick, Kim, Mindee, Logan, Nate, Kyla, Sue, Jerry, Carolyn, Steve. Motion fails.

Asa Bradman: There would be a cover letter with this, and I think that we talked in the cover letter asking for some specific information – is that correct?

Kyla Smith: I would be in favor of putting in the cover letter that we are looking for specific answers on the legal interpretations on whether or not the ion exchange resins – how their definition within FDA in regarding to food contact or direct food additives align with food processing aids.

Amy Bruch: After the cover letter and that gets answers, does it return to subcommittee?

Steve Ela: I think the intent is to give some information back to the Board, and after that I think it depends what the NOSB and the Program would like. I think that bridge is crossed down the road.

Motion to accept the proposal on ion exchange materials.

- Vote: Yes – 14; No – 0; Absent – 0; Abstain – 0 . Motion succeeds.

4:35 PM ET: Other Business & Closing Remarks

Continuous Improvement and Accountability Act

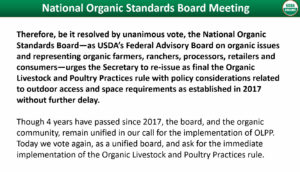

Steve Ela: A bill that was introduced this morning about Continuous Improvement, noting that USDA has failed to implement and has run into issues with key organic standards (like OOL, OLPP, greenhouse). I’m excited about this bill. The Continuous Improvement and Accountability Act will require the USDA to put together an action plan on past NOSB recommendations.

NOSB agenda review

Steve Ela reviews adgenda items for the Fall 2021 NOSB meeting.

4:45 PM ET: NOSB meeting adjourns

Thursday, April 29, 2021: NOSB Meeting

12 PM ET: Call to Order, Materials Subcommitte (MS)

Steve Ela confirms that all 14 members of the NOSB are present at the beginning of the call.

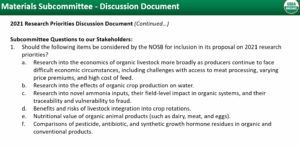

The Materials Subcommittee (MS): 2021 Research Priorities

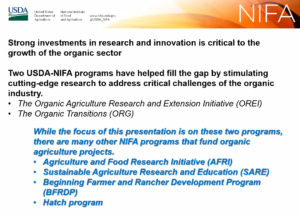

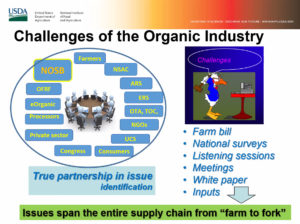

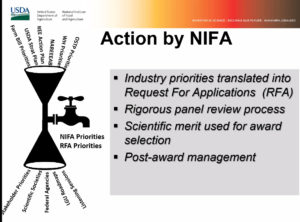

Wood Turner summarizes the issues, public comments: Appreciated the NIFA presentation yesterday; it helped clarify the evolution of research priorities and the thinking involved after the NOSB submits them.

Research priorities include the use of methionine in poultry, breeding programs for animals well-adapted to living outdoors, carbon sequestration, and more:

Some comments have indicated a need for research on heavy metals in baby food, clarity regarding sanitizers, and other issues.

NOSB has used draft guidance as part of the Sunset process, and community feedback suggests this is inappropriate and should be discussed more widely.

Sue Baird: Some comments suggested we remove some of the research priorities. NIFA presentation suggested we leave these items on the list. The efficacy of natural parasiticides and methodologies was added for poultry, as fenbendazole was not allowed on the National List.

Brian Caldwell: Amazed we’re still asking for research on parasiticides. Was involved when NOFA-NY first wrote standards in 1998, and they were asking for this information then. Surprised more is not known about this now. Wonder if we could consolidate research to make it easier to find.

NOTE: For Cornucopia’s thoughts on both the parasiticide Fenbendazole and methionine, check out our 2020 public comments. More information on organic poultry can also be found on our website.

Rick Greenwood: Re: human capital – We really don’t know what happens once these research priorities are added; have they been resolved? Never previously understood the link between this list of priorities and NIFA. It is very helpful to know.

Kyla Smith: Notes that an important link is missing in terms of getting the research to the people who need it. How can we get the finished research to the farmers, consultants, and others?

Amy Bruch: I know these research priorities are relevant, but some of these are in our current work agenda. Despite the request to not prioritize the list, we do have clear priorities.

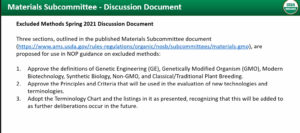

Excluded methods (EM)

Mindee Jeffery: As a board member, tried to educate everything the board has said on this issue. This discussion document is meant as a ‘how can we reset ourselves’. Learn how excluded methods are impacting supply chains. Take the public comments and contextualize them. Major reflections from stakeholders can be organized into 5 buckets.

5 general buckets of types of commentary on this topic (including a summary of quotes and comments from stakeholders):

- Commenters request to move forward on 2016 recommendation. All major stakeholders recognize importance on this course of action. [MS discussion documents can be found on this page.]

- Comments from the seed community. Seed use long tethered to excluded methods discussions. Commenters want help to support and bolster organic seed usage in the community (because there is still not enough available seed, some folks may be using seeds produced via excluded methods). MS needs to tackle seed issue in particular as EM issue and standalone issue.

- Response to “To-Be-Determined” (TBD) list (terms that that not been TBD whether they excluded methods category). Difficult to track these issues while also concerned about field sprays. The clear and consistent request to act on the TBD list in the fall meeting with a lot of information on how that will affect farmers. That was a big push from farmers. One quote from a seed producer asked the NOSB to make recommendations clearly. Breeders need to know if and how they can serve the organic community. Good information from a seed group that outlined how our recommendation on this topic will affect farmers.

- Transparency and protection. Comment summary: info about tech form USDA need to be free flowing; updates to regulations need to be timely. Manufacturers have the authority to determine if their product is going to be regulated; this is problematic. Sec. Needs to be held accountable to organic co-existence with markets that allow GE products. The FDA has no mandatory requirements for food requirements and technically has the ability to assess animals.

- Urgency factor: Comments from retailers, etc. that this urgently needs to be resolved and tracked closely. Consumers are passionate about keeping GMOs out of their food, and when they say no GMOs, they mean it. This is the space that they rely on us doing our jobs so that they can eat in a way that they understand.

Mindee Jeffery: This is a big subject. We will have time in subcommittee to go over all of this feedback.

Wood Turner: Giant piece of work. Want to acknowledge your work on this issue. I feel like we’re in good hands.

Brian Caldwell: Amazing job of condensing all of those comments. I appreciate that Jenny Tucker spoke at length a couple of times to us about excluded methods. One of her points was that the existing definition under the regulations really does cover a lot of ground with EM. Maybe trying to capture all of the new forms of GM that may come out and gene editing and everything like that isn’t as important as enforcing what is already known. Maybe what we need to work on is a mechanism for exposure – thinking about seed varieties mostly, but maybe can extend it to other things in process. The TBD list that we have is about cell fusion, but it is actually specifically named in the definition of EM that it is excluded already (so I’m not sure why it is TBD). Question of how to retrieve varieties that have been in use for a long time; may have to realize that we live in an imperfect world. Demeter has never allowed cell fusion (see article from 2008). Maybe enforcement of the rules that are actually in the regulations is a way to start on some of this and then moving forward from there rather than trying to specify all of the methods that are coming along. They should be captured already if we can ask for information in that transparency part that you talk about from the seed companies. It evidently totally works for GMO corn and soybeans. We should be able to do the same thing with other vegetable varieties with EM.

Jerry D’Amore: I would like to acknowledge your great and thoughtful work on this. I believe this is a path we have to go down with vigor.

Kyla Smith: ACA Materials Working Group did develop together an affidavit for EM that is mostly used for handling ingredients that does take into account the technologies that have already been voted on by the NOSB and lists them specifically for manufacturers to say that they have or have not been used. I know that is about handling, not seed. Question: Mindee talked about in your first bucket urging the program to move forward with the previous recommendations, and based on Jenny’s presentation on packaging things together, wondering if it would behoove us as a Board so this could all get packaged together into one rulemaking or guidance?

Jenny Tucker: Important conversation and insightful – this will continue to emerge – encourage people to read the regulations so that we can frame this into the “we think this is already prohibited because the regulations say this.” To Brian’s point, we are enforcing the current regulations, which area already quite broad. I think it is a very solid umbrella. I think we need to think of how we are framing all of these examples in a way that someone doesn’t say “this isn’t on the list, so it must be allowed.” No, it is a broad definition of what is not allowed here. Need to think about what we most need in a practical way to give certifiers what they need as a practical cool and not open up any loopholes, and then look at how frequently we need to update it.

Kyla Smith: Would it be worth making very clear on our cover sheet what we want the Program to do with this whole package – would that be helpful? I know there hasn’t been a lot of movement in guidance, but as a certifier we really rely on guidance.

Jenny Tucker: This is not an esoteric discussion. These are decisions that certifiers need to make every day. Connecting that to what certifiers need to do is so important in this dialogue for consumer confidence. Really important conversation. I want to help move this along. Let’s remember how strong our existing regulations are rather than have people question it. They are strong. These are prohibited. These are excluded. Let’s always put that first.

Nate Powell-Palm: In tacking on to Kyla’s point – it is not boring at all how we figure out the nuts and bolts and minutiae of how we do this. I want to upvote what Kyla said about wanting those guidances and moving forward with past recommendations on this topic.

Mindee Jeffery: I think part of the pressure comes from the overwhelming development of biotech.

Steve Ela: Just like BBMF and the arguments of where we said, “Not derived from excluded methods,” and I think that to Jenny’s point that is true, but we also see in the fermentation process that creeping in…and we keep bringing up that if the product doesn’t contain excluded methods, is it okay? I would personally say it is not if it was made with EM – but the question is how far back we go. We need to not just focus on definitions, but larger filters that we can run things through to determine if it is or it isn’t a EM. I think it is going to be tough going to keep the prohibition a prohibition without something sneaking in. So glad you are working on it.

12:45 PM ET: Compliance, Accreditation & Certification Subcommittee (CACS)

Discussion Document: Human Capitol Management

Proposal details for this discussion can be found here (this includes the contents of the slides).

Nate Powell–Palm: Kick this section off with history of myself. For ten years, I’ve travelled and worked for a lot of different organic companies. Initially had decided to take an inspector course to get better at paperwork and his own inspections. After taking course, realized there was this underground world that made all of the work possible. When Jenny came out w memo on human capital, whole community said this was something that needed to be addressed. We’ve gone from state to state to $60 billion industry + need qualified professional certifiers to protect integrity of organic. Shout out to Jenny for recognizing important work of inspectors while going forward w resilience in mind.

When the memo came out, a lot of people kicked into high gear. A lot of folks like Oregon Tilth wants to change how things are done thanks to memo. Commend the leaderships in acknowledging the deficits in the profession.

Sue Baird: This has been a great project. Thanks to Jenny and the staff. Wanted to highlight a few things from the human capital document. Asked questions to inspectors: what compelled you to become an inspector? What compelled you to stay in the profession? If you left, why? What are challenges you’ve ID’d as an inspector or to becoming an inspector. Common points we heard: cost + travel time. Positive and negatives on the ability to travel. Professionalism – it appears that some of our inspectors have experienced a lack of recognition that they are professionals. What causes this? 3rd point: compensation for experience. How do we build professional experience as inspectors? What was the environmental impact of travel, how does the job impact personal life? Lack of consistency for certifiers when it comes to insurance etc., which has led to certifier shopping among inspectors.

Responses were overwhelming from individual certifiers, certifier entities, and from IOIA. Commend putting out the survey to certifiers.

There was interesting challenges – how do we go about addressing? There is a lack in the inspector pool. Experienced people in the industry do not want to travel or lost family time. Family is a major consideration for inspectors – a lot of time spent away form family. Providing insurance is a huge issue.

First of all, was perhaps we need to implement a risk-analysis of those certified entities that have more of a risk factor and focus our move in depth inspections for those entities and save the lesser risk entities for a lesser risk inspection. We would have to identify parameters of high risk.

Second strategy identified: How do we apprentice these new inspectors so that the concept of professionalism is ingrained? How do we ensure our industry that the integrity of our products is being maintained?

Kyla Smith: Some things that I saw in the public comment are, as in the proposal, the way that the proposal was structured – there could be entities doing pieces and parts of this – an apprenticeship program, career development, training, etc. Some other commenters talked about a more unified approach through a credentialing program – take those elements and wrap them together into one thing so it’s not so parsed out. Other thoughts from Board members if one strategy is better than the other? Is there an appetite from the industry to have a more centralized certification program – cover qualifications and tiering of entry level, mid-level, expert that would have some pay and other qualifications that go along with it.

Nate Powell-Palm: Wanted to jump on that. When we look at the acute bottlenecks – the apprenticeship program – and how we get that practical training to inspectors, I have always admired how close to the community and grassroots IOIA has been able to remain. Coming up with an entity that is closely related and equally grassroots – such as what Angela & Garth Kahl mentioned – would make it so that we have a fundamentally acknowledged standard of training but also able to fill that bottleneck.

Sue Baird: I agree. I did hear comments that a lot of the respondents would like to see us somehow aligned with secondary education. Some respondents noted they would like to get CEUs that they could then transfer to other things. Interesting and has a lot of validity. If you are going to spend $5,000 for training, it would be nice to get some college credits for that.

Nate Powell-Palm: I couldn’t agree more. If I were to paint the world I would like to live in, I would see IOIA working with a university to make a standardized 2-3 credit course. As a training for IOIA, I could definitely fill 45 hours of lecture time with all of the minutiae that goes into being a good, observant inspector. I think marrying this with a university for a more formalized education component would work really well. I do really like how IOIA has been able to maintain their relationship with the inspectors who are actively working on the ground. I think there is even more potential with the university component, as we would be better able to target schools that are not in the organic realm right now. I think that would be a way to tap into broadening the organic tent, as well. I would tap onto that that personally, I thought it was a real steal to be able to spend $5,000 to jump into a career that would pay me more than anything I could get into from my undergrad degree, which was more than $5,000.

Amy Bruch: So important with the impending SOE, with more strain on certifiers and inspectors, getting them the training now is more critical than ever.

Steve Ela: In this training, if we could help ensure that we have diversity; that we not just fall into the trap of the normal “look” of inspectors. Black colleges and such that we could reach out to to ensure that our inspectors represent a wide diversity.

Motion to vote on forwarding the proposal on Human Capital by Nate Powell-Palm. Second: Mindee Jeffery .

- Vote: Yes – 14; No – 0; Absent – 0; Abstain – 0. Motion Passes.

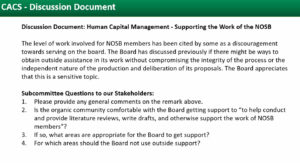

Discussion Document: Supporting the Work of NOSB

Nate Powell-Palm: As a first-generation farmer, I realize what a stretch it is for volunteer work. And that is true of a lot of people, and we miss out on a lot of great talent because of that. Thinking about how to make this more accessible to more people, this discussion document is a first stab in trying to figure that out. What can we do to make it so that the lift isn’t so insurmountable?

Steve Ela: I appreciate both the CACS and the Program bringing this up. There were a number of comments that we should open an online docket between NOSB meetings for a more transparent information sharing and help NOSB members with information processes. Although we did not manage it this time around, in general we do open the docket between meetings, but that is largely unused – by both stakeholders and the Board. It is always difficult for the Board and subcommittees because our turnaround time is so tight. The time for a lot of exchange is limited, but could be used more so that proposals reflect stakeholder comments.

We also know that there is a lot of concern about undue influence from the Program on the Board, and it was really heartening that all of our stakeholders were in favor of this. Comments were great that worries that the Program having too much control could be allayed. Number of commenters noted they would like the Board members to have some autonomy in making decisions on what kind of help they received. Thoughts were really of providing NOSB members with more technological support, where someone could really provide some help. We already have the TRs, which are hopefully able to provide this, but they have a fairly long turnaround time and are expensive. Looking to have something more readily accessible to the Board. Another recommendation was to have some help around regulatory language around what our intent is so that the Program does not have to interpret in the regulatory language what we meant.

There were some comments that the NOSB members should author their own Discussion Documents and Petitions, as that is the intent of being on the NOSB. Others noted that it would not be appropriate to have outside people summarize or abbreviate the public comments, but that the Board should reading them.

I was pleased by the support and encouragement for us. I know serving on the Board does take a lot of time and may prohibit individuals and those from small businesses to participate.

Any thoughts?

Asa Bradman: Michelle clarified for me that as part of OFPA that participation on the Board is without compensation. Want to emphasize that it also limits people, as well. Not just time, but also money. When we think about diversity…of course we cannot contravene OFPA and that specific designation, but I think that as we think about resources, that could make the difference on that.

Nate Powell-Palm: Thank you, Jenny, for getting this conversation started. Looking forward to moving forward.

1:25 PM ET: Handling Subcommittee (HS)

Jerry D’Amore, Subcommittee Chair leads the HS discussion.

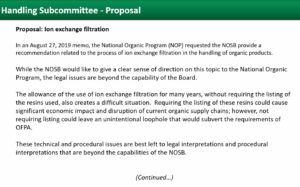

Proposal: Ion Exchange Filtration (IEF)

Steve Ela: Ion exchange was sent from the Program to give recommendation about how ion exchange materials should be handled/certified. This report is updated from the more concrete proposal in the fall that was voted down.

As a high-level reminder: there are many different aspects of em that ion exchange involves.

Widespread agreement that recharge materials should be on National List. Resins in the column have ionic points where ions are attached. As you run them through the column, those ions are exchanged. Sodium ion in the resin may be exchanged for something else we don’t want in the food product. Over time, the ions are spent and must be replaced.

The big disagreement is regarding the resins themselves and whether they need to be on the National List. Are they food contact surfaces, such as piping, tables, and o-rings? Or are they secondary food additives that contribute things to the final food product?

Some commenters noted that ion exchange may introduce chemicals into the food, but they do break down, and they should be listed. There is precedent for their listing in boiler water additives, etc.

Other commenters claim the resins do not belong on the National List. Gets into legal issues that may be beyond the resources of the NOSB. Program should get involved.

FDA regulates food contact substances, and they are not intended to have any technical effect in the final product. It can be argued that the resins themselves are not intended to have a technical effect – just the resins attached to them. The resins themselves are “inert.”

It was noted by one commenter in response to the fact that some of these other items do need to be on the National List that there are processes that can change a product that do not need to be on the National List – baking, for example – it could be argued that some things we allow and some things we do not.

It was mentioned in the public comments, and comes back somewhat through the Harvey lawsuit, and in that lawsuit they interpreted ingredients as including processing aids. Processing aids are something that are included in the food for a technical effect. It would seem that would indicate that processing aids do need to be on the National List; however, in 2002, the Program had issued a policy about what “still present in the food” applies to: ”…substances classified by the FDA as food contact substances are not subject to this definition.” FDA’s classification really does affect whether or not these materials need to be on the National List.