Join The Cornucopia Institute as we keep you informed via web updates from the National Organic Standards Board (NOSB) meeting online.

We will be sharing the play by play of the meeting on October 24, 25, and 26 below.

For background on issues up for discussion at the meeting, see:

- The NOSB’s Proposals & Discussion Document for Fall 2023

- Cornucopia’s formal written comments

- Cornucopia’s notes on the oral comments for the Fall 2023 NOSB meeting

- Additional information on this meeting and past meetings dating back to 2012

Tuesday, October 24, 2023: Fall NOSB Meeting, Day 1

Call to Order, Agenda Overview, NOP Introductions

Jennifer Tucker, National Organic Program (NOP) Deputy Administrator makes some introductory remarks and introduces the NOP staff.

Dr. Tucker: We have new roles and saffpeople at the NOP: Heather Kumar and Esu Obu are scientific liaisons – new roles. Positions based on NOSB recommendations. We also have a new Associate Deputy Administrator. Previous Associate Deputy Administrator, David Glasgow, got job back home in TN. Andrew Malone is new Deputy Administrator and comes from Dept of Treasury -Alcohol and Tobacco team there and has significant labeling experience. Also Andrew was previously with APHIS. Been on board with NOP for a couple of weeks now.

NOSB Introductions

Nate Powell-Palm, NOSB Chairperson

Role call of the NOSB members: Javier Zamora, Mindee Jeffrey, and Carolyn Dimitri are absent at the start of the NOSB meeting. All other NOSB members are present in person.

Current members of the NOSB can be found here.

Previous NOSB members can be found here.

Secretary’s report (acceptance of Spring 2023 meeting summary as official record)

Amy Bruch, Secretary

Minutes from April 2023 meeting are approved.

NOSB report

Nate Powell-Palm, NOSB Chairperson

Nate Powell-Palm tells his narrative about growing up with severe asthma and how his mother worked tirelessly to give him organic food to cure it. Nate also shares how he became a farmer and organic inspector. “Fighting for a future our kids can be proud of.” “Organic has been a refuge from economic violence.”

USDA/AMS/National Organic Program Update, and NOP – NOSB Q&A

Dr. Jennifer Tucker, AMS/NOP

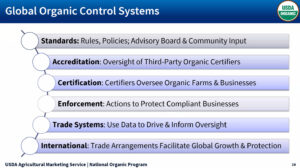

NOP Update from Dr. Tucker: Learning Center is a free resource. Included TOPP update. Log-in to the Learning Center to catch up on presentation. NOP team has about 88 people with natural ebb and flow. Folks are distributed across 5 key groups: Standards, Accreditation, Compliance & Enforcement, Trade Activities, and Office Deputy Administration. 20-25 people b/w Accreditation and Compliance and Enforcement. Right now have team in India doing on the ground audits of certifiers there. Compliance and Enforcement process incoming complaints – half complaints are uncertified operations selling as organic. The other part of team is split b/w Livestock and Import Oversight. All concerned about Import Oversight and have a whole team dedicated to it. Trade team is all about international – about 15 people – didn’t exist 5 years ago. Include folks who oversee equivalency and recognition agreements. The rest are responsible for data and systems work. They work with import oversight group.

You can learn more about the NOP and the certified organic requirements at the Organic Integrity Learning Center.

The Office of Deputy Administrator runs the Transition to Organic Partnership Program (TOPP) as well as the Organic Insider, and work with the budget office. We also have a customer service team to field questions from farmers. About 2/3 are not in located in D.C. and are working remotely. We now have folks across the country.

One year ago, we launched the first iteration of TOPP map showing all the partners. There are now more than 180 partners engaged at different levels. More than 165 events in just one year and in our online application system we have 80 formal applications to be mentors. We had through all events have touched 11100 people. Over 1000 people per month have be touched by TOPP per month.

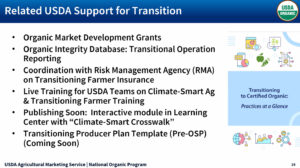

Transitional continues to be an extra-regulatory part of the program. Regulations don’t say a lot transition so we have issued a memo that we’ve issued. Not publicly posted data, but a way for us to communicate with RMA about who is qualified. Transitioning Farmer Insurance – making progress. Have also done live trainings for climate smart ad (over 120 people have taken part). Have micro learning in Learning Center for transitioning farmers. Interactive module on climate smart will come out soon. Soon we will publish Transitioning Producer Plan Template, a “pre-OSP”, a glimpse of what practices are and what transitioning farmers need to be thinking about (developed in collaboration with ACA).

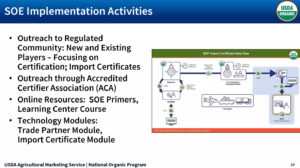

We’ve been spending a lot of time and focus on implementing SOE. Stakeholder input on Farm Bill matters a lot.

The NOP has been doing outreach about SOE through ACA. Trying to find alignment and consistency among certifiers. Recently launched learning center course about what rule says and why it matters – gives idea of what trying to do which is helpful in understanding implementation. Also been launching technology modules, including Trade Partner Module, to get them set up in OID. It’s called Global Integrity Database in which operations exported to U.S. will be reported. This module will issue import certificates. Certifiers can start generating import certificates – gave certifiers a head start. Have already generated scores of certificates. If you are wondering what certifiers are doing, ask them if gone into Import Certificate Module. If representing export community, ask how your certifier is getting ready for SOE. The module was launched 6 months before implementation.

Certifiers have the ability to easily exit the market. If they can’t get into a country to do unannounced inspection, they shouldn’t be working there. This is example that SOE puts in place to tighten controls around the world. Trade systems uses data, CPB data, and updated MOUs about dating sharing across agencies and has opened up world of data. International trade arrangements intended to protect market – not just about standards, it’s about systems we use respectively to oversee the markets we control.

The NOP team has put a number of courses in the Organic Learning Center. The livestock team regularly posts a new course based on courses we are seeing. Done a number of courses on import oversight, quantitative methods, and math training. Surveillance on complex supply chains – if credible concerns about a region or tremendous growth in region, these are all indicators that we need to be ahead of the curve. We now have a team that can quickly initiate supply chain surveillance. Certification of everyone in supply chain protects all of us. We’ve issued a number of certifier directives – advanced testing, mass-balance and traceability exercises. New legal penalties covered by trademark protections. We have activated trademark protections in Customs and Border Protection (CPB) systems – gives us the ability to hold products and turn away shipments. CPB has special powers with trademark – often hold products at the border. CPB also charges to hold products at the border while under investigation. The goal is to make fraud to expensive to make it worthwhile.We also have seen cases of prison time for fraud.

Last week we had the team taking samples in Baltimore. This is extending to other ports. Through OIG work with DOJ on criminal cases.

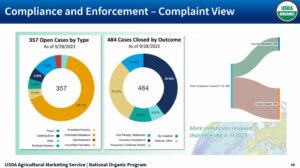

Voluntary compliance means the operation stopped the noncompliant conduct and perhaps paid civil penalty. Improvement in efficiency. We have resolved more complaints than we received. About 350 open cases. When cases involve OIG can be open for months or years.

![]()

When we close an NOSB recommendation we try to give a brief explanation of why. Have addressed over 90% of NOSB recommendations since the start. Regularly report to NOSB through memos which are publicly posted. We expanded memos with section that talks about regulatory priorities for upcoming semester. OMB regulatory agenda is definitive place to find out regulatory priorities.

The NOP’s vision of “Consumers Trust the Organic Label” needs help from everyone in the room and listening.

Question and Answer: NOSB Questions for the NOP

Nate Lewis: Please elaborate on the SOE trading partners?

Dr. Tucker: We have trade arrangements with other governments where we have agreed standards achieve the same goal for fair trading. In my mind the system itself is important. How are the governments doing control system points. We have started conversation with other governments on updated equivalency arrangements which means they may need to make changes to remain equivalent with us. The EU recently updated regulations so we’ve started that dialogue. With Canada, dialogue has started with supply chain traceability audits – put in place before challenges emerged – so we’re having honest conversation about risk. We’re having a conversation with every trade partner and will be some difficult conversations. U.S. has put real investments in organic protections and raises bar for systems around the world.

Allison: Received comments encouraging us to look at equity commission and how we can build more inclusive organic sector. How can NOSB engage commission?

Dr. Tucker: TOPP program incredibly exciting and will hear from Northeast groups with incredible stories. Equity Commission background: put in place a couple of years ago and purpose is to make enduring changes to policy that eliminate system discrimination and oversight of civil rights issues. Secretary level commission – meet 4 times a year. They gave first report Feb 2023 with over 30 recommendations to advance racial justice. Agencies across USDA get a copy of recommendations and look at programs and see what we can do. Already been changes within AMS. Regional food business centers program is designed to assist small and mid-size producers overcome barriers including communities not previously been part of it before. Not waiting for equity commission – organic has been proactive in engaging tough conversation and one of national partners lead by OFA charged with bringing groups to conversation not previously part of conversation – takes us all having one conversation at a time. Lots of stories from folks not part of community that we want to hear and starts by asking what their story is. Encourage all to do that.

Brian: We get hundreds of comments from consumers and this time got a lot about toxics in plastics and hydroponics. How can we move forward and respond to these concerns about hydroponics and toxics in plastics?

Dr. Tucker: Plastics topic: zooming out, one of benefits of current food system transformation effort is helping consumers about where food comes from and how it’s produced. No denying there is a lot of plastic in all of agriculture. Organic is often a very focal point because of its openness and transparency for these concerns to bubble up. This is a broader experience in agriculture. This group has taken on some of that work on discussion on materials and in general. We have the National List deliberation process within this body’s work and you have used those well.

Hydroponics – another area where a lot of plastic is used, going to broaden out to containers and lots of questions about soil-based and soil less production. Containers is a topic that we are cognizant of and had a high place in regulatory priorities. Close after the 3 big rules: Origin of Livestock (OOL), SOE, Organic Livestock and Poultry Standards (OLPS) – those rules and advanced rule writing related to nitrogen and NL work have been a focal point. We hear that containers remains a priority for the organic community. We need to finish some of these rules [first] and effectively implemented them. And we want to emphasize OOL and done comprehensive review of certifier compliance. We want to make sure not just putting rules out in the world but following through on implementation. and enforcement. If container rulemaking were to proceed, need to be thought out. Some have said advanced rulemaking could be way – need to think about a policy process. It’s still on our minds as important priority for the community

Brian: If we can target known toxics with annotations; for example disallowing the use of PFAS or phalates in production of organically approved plastics – is that an avenue we could take? Plastic waste is a huge problem.

Dr. Tucker: Annotations are a valuable tool. Only comment is that as working on annotations, always have in back of mind what certifiers are going to have to do. Have certifier voices in your head when working on annotations so they can implement and enforce.

Amy: A message from heartland – times are tough. Corn and soybeans producers have limited markets and price compression. Many producers in corn and soy are taking acres out of production or contemplating doing so. I believe it easier to retain organic producers than transition new growers. Talk about concerns about bringing new farmers in grain world?

Dr. Tucker: Everything is connected. For TOPP to be successful we have to do enforcement activities. Have to have fair market. Import oversight program is making a difference – have seen large shipments that buyers in US refused and testing revealed prohibited substances.

In a difficult transition period to protect the market. We also have OTA partnering with Rodale hosting events to explain buying and what those contracts might look like. Also resources available to existing farmers don’t want to use. WE need to work on all fronts to have folks in US feel safe enough to make the jump. Why SOE is so important. If certifiers are overseeing exports, we need SOE to hold them accountable. Only through oversight and protection that people will feel safe to stay in the market. Import oversight, TOPP, strong clear standards – all part of a system.

Kyla: Several comments related to imports. Related to the testing – certifiers required to disclose results. Is there another way, NOP can be transparent on testing and results since still concern.

Dr. Tucker: Sampling and testing is important. Now that have CPB have a better sense of where to go and doing more targeted surveillance. WE actually know when ships arriving. Our annual enforcement report is avenue for doing more reporting. Farm Bill had reporting requirements. Along with that and our report, we report on the activities we are doing – fine line between transparency and letting bad guys know what doing. Don’t necessarily want everyone to know. When went to India did a broad testing program and lead to noncompliance for certifiers on the ground. If these are open noncompliances and not resolved, we move toward suspension. Very sensitive about showing had too much.

Jerry: In lag time for SOE to be meaningful. Believes fraud concerns will diminish rapidly with time [due to SOE implementation] and hang on to saddle.

Dr. Tucker: Sensitive about exemptions. A lot of emails say “only doing, then don’t need certification.” I find that alarming and if we get to next spring and summer, and exemptions, this only works if we are all in and not looking for loopholes. It will take time and already had a lot of time for folks to get certified. The rule is hard where the risk is high. It’s not supposed to be hard where risk is low. Want to read the rule in this context. Small farmers should not be overly burdened – it’s where the handoffs are where high risk.

Jerry: Dealing with segment of supply chain not used to having people tell them what to do. One segment still concerned about. Major retailers and even more from those who don’t know what don’t know. I’m worried about the clueless.

Dr. Tucker: Hoping level continues to drop every day. need to push the word out – how do I help – be thoughtful which stones throw. There might be a lot of stones in this room that have ripple effects beyond what we realize.

Nate Powell-Palm: [Notes that Carolyn Dimitri is now present.]

Amy: Even more difficult with geopolitical challenges, wars, and high-risk countries – can you speak to work on integrity with imports given these additional challenges?

Dr. Tucker: A number of certifiers overseas have exited the market due to no longer have administrative capacity. Keep an eye on the number of certified operations. Certifiers can only go where they can do unannounced inspections. What about NOP oversight of these certifiers working in countries where we can’t travel to? That is active conversation that team is evaluating. What are regulatory constructs around NOP capacity to oversee certifiers operating in those areas. If we suspend a certifier because they can’t inspect these farms what happens to those operation when the war is over – gets messy really quickly. On our internal work agenda that we are working our way through.

Carolyn: Realize conversations around organic are so much more complicated than ever thought before getting on the Board.

Nate Powell-Palm: Talk about cross-walk for climate smart. Could you tell us about climate smart cross walk? Organic should be considered climate smart. How have you taken proposal and build something out of it?

Dr. Tucker: NOSB started with a letter to the secretary outlining observations of administration’s engagement with climate change and talking about organic’s role in conversation. This turned into a work agenda. A lot of great feedback. Ended up being an NOSB recommendation. Developed nice piece and talks about possible offerings of NRCS and how regulations support climate smart agriculture. This ended up being a PDF document shared with others in USDA and we’re translating this into interactive module that we’ll put in Learning Center. Part of the goal is that if you’re an organic farmer and want to qualify for conversation benefits, for example, can more easily see what parts of OSP covers this. So much talk about regenerative, which makes the point that organic farmers are already regenerative.

LUNCH BREAK

Transition to Organic Partnership Program (TOPP) Presentations

Speakers and introductions are all for the Mid-Atlantic/Northeast TOPP. More information about the TOPP program can be found here.

Dr. Tucker: We are now moving to an update and presentation from the NE TOPP Region. Diana Kobus. I wanted to compliment this region. This region has a whole lot of states in it: includes all of New England and extends down into West Virginia and Virginia, and the whole Chesapeake Bay area. There are lots of states and diversity in farming practices and demographics in that region. I was privileged to join an early bringing together of partners and an early tone of collaboration in that region.

Dr. Tucker introduces Diana Kobus, the Executive Director of Pennsylvania Certified Organic (PCO), the Northeast regional lead for TOPP. Diana joined PCO in 2020 and has over a decade of leadership experience in environmental and public health professions. She has a masters in Environmental Science and Management and an undergraduate degree in English and Communication studies. She was the ED of the Institute for Environmental Professions. She also worked at Whole Foods market in the early 2000s and urged her to educate the public about the standards and food labeling. She brings a strong passion for organic production and was born and raised in Pittsburgh. She is there to help farmers at PCO and finds great joy in interacting with stakeholders.

Transition to Organic Partnership Program (TOPP) Presentations

Diana: The Northeast is home to leaders and where organic markets are yet to be developed. PCO intends to leverage a network of leaders. Have 9 core partners that includes 13 states and DC – highest of any TOPP region. We have termed the region a partnership, not a center, to represent our ethos. Our goal has been to create a strong network with a central contact in each state to create connections to transition.

Featuring a mentorship dairy to tree fruit – Russell Wallack – 600 acres. Can look at Breadtreefarm.com. No interstate highways and barely one DMV. We believe this area could become breadbasket of NE. Stewards approximately 600 acres without toxic chemicals. Regenerative chestnut production. On mentor side, we have Brian Caldwell, founding member of NOFA NY. This is an example of farmer to farmer relationship TOPP is building.

The Transition to Organic Partnership Program (TOPP) was recently launched!

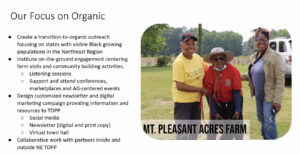

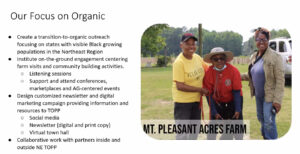

We are also working with the Black Farmers Index to increase diversity. We are eager to further connect the work of the organizations serving their communities. Foundational community building is work that builds lessons for all of us. This will provide a template for urban farms to transition to organic. NOFA Mass has created a program to have sovereignty over their relationships with the organic movement- addressing inequities in the process. Kaia Shivers is president of the Black Farmers Index.

Dr. Kaia Shivers: Started the Black Farmers Index in April 2020. Who will be affected first when there is a food shortage, and how can I be part of the solution. As a result of being forced out of the agrarian lifestyle… commitment to bring as much food directly to consumers from farmers to answer how they survived generations of inequities. We now have 1200 growers listed in our index. Since expanding we are trying to ensure Black farmers are fully included. During our journey we were imbued with generations of agricultural stories, many of which were left out of the nation’s narratives. The methods used were organic and climate friendly, but they rarely used the term organic. Tradition. The old way. Heritage. Heirloom. So committed to the land were Black Agrarian societies, that farmers protested toxic soil being dumped in their communities which sparked the environmental justice movement. They were largely absent from the organic industry. These references to ecologically smart farming have been hijacked and remixed. They have a fraught relationship with USDA. If we cannot equalize organic now the whole industry will be impacted. Several people saw our work as important. Working with NE TOPP, we plan to use our on-the-ground relationships to build a community of growers who are certified to pass on a rich cultural knowledge of growing. We will be very busy. We will meet the farmers where they are literally, with intimate visits with honest conversations about needs, interests, and questions about transition. We will also work online for those who are savvy, and also with those who do not even own a computer. We will conduct town halls and listening sessions. We will customize a culturally competent experience. Farmers do not want handouts. Farmers do not want handouts. They want their space in the market and the resources and support that is owed to them. Dr. Ahmen studied in Japan to learn better rice harvesting methods. We helped him plant rice in May. Dr. Ahmen is certified and has become a go-to in Black farming but is undervalued in the larger organic space. Mt. Pleasant Acres farm, the “Aunties” are transitioning the land her family worked previously. This is the land Harriet Tubman’s family worked. We know farmers are committed to organic but are left out of the industry that has developed so many blind spots that must be corrected! Thank you for your time.

Diana: Thank you to Stephanie Jerger from OTA for connecting us. Each of us [in the NE TOPP cohort] have 2-3 minutes to talk about our states’ efforts.

Pennsylvania: PCO shares responsibility for Maryland and Delaware. Challenge to transition is substantial and we are up for it. Pennsylvania is the only state with its own farm bill and home to most farmers under 35. Have opportunity and will lead transition. One event was Rodale’s Annual Field day where students learn from pioneers. PN Sec of Ag and governor came to support the work – governor said if want to grow economy, must invest in agriculture, and organic is key. PCO continues to build networks in support of TOPP.

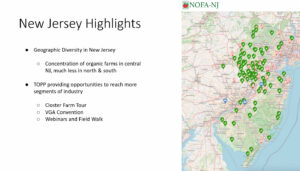

Devon Cornia from NOFA (NJ): New Jersey is a very diverse state. Organic farming has historically been clustered to the wealthy parts of the state. Through TOPP we now have the resources to reach more parts of our state that haven’t been there before. Relationships are the foundation for all of the work we do. We don’ t have great relationships within our industry- organic and conventional farmers don’t understand one another and organizations don’t always get along. We are working to get a fix on those relationships. This is a 10 year deliverable that TOPP will have an impact on. To repair these damaged relationships we are drawing conventional and organic producers together. We are having conservation webinars and nutrient management webinars to engage folks that aren’t as engaged in the more crunchy side of things. Webinars, Field Walks (livestock and crop farm), supporting underserved producers on an incubator site. We will be ramping up community outreach. I want to give a shout out to our partners. It has afforded us to work with these amazing people.

Teresa Downy: NOFA-NH is working with partners to develop events to assist transitioning farmers. Several on-farm programs have taken place and provided community building for those wishing to transition to organic. Grassland management workshop – farmers walked host farm fields. Another workshop, shared info on manure management from structures and materials to producing manure and managing manure. Another workshop involved strategies for growing potatoes where farmers were shown methods of field rotation, pest management, and restoring equipment.

Laura Davis (from NOFA Massachusetts): I am a board member and organic certification assistance coordinator. I do some soil analysis as well. My job came out of Sound and Sensible. Since then I’ve been working to help farmers and food processors navigate the organic certification process. I also am an organic vegetable farmer and co-chair 7 NOFA chapters. Really exciting to me is our partnership with UMASS Amherst with their ag school. They had always told us they teach people how to farm. IT’s up to the farmer if they choose organic or conventional. We were able to sign them up to develop and deliver a series of 7 workshops for organic growing. This is a picture of me and Congressman McGovern. He brought 30 people to my farm in August (NRCS, FSA, Rural Development). He said we have to get the word out about TOPP! He has been a big supporter of agriculture.

Diana already talked a little bit about the NOFA Mass Equity project. We have been working on equity for 6 or 7 years. Dismantling racism trainings happen every 2 weeks for staff and board. That has made a difference for the board, staff, and those who come to our conferences. This has helped us to reach farmers of color.

We are looking forward to continuing our outreach. Figuring out how to crack the nut of getting in front of conventional farmers. We have 10 farmers signed up to transition. They are all growing organically now… how do we get those Farm Bureau people to sign up? We have 10 ready to go and they are all eligible in 2024. Our mentors and mentees will be able to take advantage of the soil health services we offer. We appreciate this opportunity!

Chris Grigsby (Certification Director at MOFGA): Working with project partners, Univ of Maine, Maine Grain Aliance, and University Maine Cooperative Extension.

Maine Grain Alliance will train and host organic heritage grain workshops. Partners will be hiring staff to support TOPP.

Teddy Tomao: NOFA-NY Long Island Transitions Coordinator and new farmer.

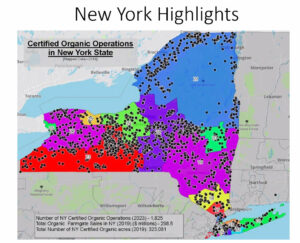

NY is the 2nd in nation for certified farms and still area to be improved. 4% of land is organic and this is about same as CA and Maine. Vibrant agricultural infrastructure and diverse production of crops. Great opportunity to transition more acres – including wheat, rye, and pulse crops. Have continued regional demand for local and regional organic dairy. For last year and half, I have been Long Island educator. With TOPP able to expand reach and can now add 3 educators to cover NY state. Have events throughout state. Have winter conference in January and planning regional events. With partners have been putting on events and now TOPP gives us opportunity to collaborate, expands reach. Done TA and workshop improvement – dairy practices, vegetable growers, and improved info on certification. TOPP has really helped with mentorship program. Matching farmers and it’s revitalizing us.

Jeremy Pelletier with NOFA Connecticut: Thank you to PCO for their leadership. I am the ED of NOFA Connecticut. In Connecticut we have a unique situation in that we have a tightknit ag community. We work well with the various players (Farm Bureau, Extension, etc.) We have 66 or 67 organic farms in our state. We are able to reach out to many organic farmers, transitioning farmers, and those who have shown interest. We have learned specific barriers to entry of becoming certified. Partnering with UCONN, we have provided TA and our Getting Started in Organic Farming will detail everything from land acquisition to organic application.

Our strength in Connecticut is with our partnerships and ability to provide technical assistance. We have 10 mentors and 9 mentees. UCONN will, for the first time ever, have an in-house organic farming specialist. They will extend their services to all farms. We are very excited about that. This will include general support. The Farmers Alliance will build cohorts and community among transitioning farmers.

Lastly, we have an organic certification expert on staff to walk farmers through the certification process. Our goal is to provide support at all points so that we can 1) ensure a successful transition, and 2) demystify the process. Thank you!

Brent Wills, Program Coordinator, Virginia Ass for Biological Farming. From Blue Ridge mountains in Virginia. Raise pasture raised pork. Get to work with other farmers who are learning organic and regenerative methods. Have few organic farms and processing in VA. There have been gaps in educational programs and being able to partner with PCO and other organizations allows us to provide much needed technical assistance. Able to extend outreach to increase awareness of organic in VA. Have a lot of gaps and wide geographic and demographic changes. Decided to focus on training the trainer. Most exciting things looking forward to is having 2024 winter conference in Roanoke, VA. It will focus on TOPP project and devote a full-day specific to organic production and it’s free for all attendees. Will also provide different workshops regionally across the state. VA is a wide state and agriculture is different in the west than in the east. Partnering with VA State Univ. b/c they are solid partner in equity in organic production. Work with farmers of color and expand diversity and looking forward to being a partner.

Spencer Moss, West Virginia: I’m the Executive Director of the West Virginia Food and Farm Coalition (WVFFC). We’ve had a little less organic action over the year. I discovered that we have about 21 certified organic farms. At the coalition, we are a statewide coalition, based in Charleston. We work at the intersection of farm viability and food access. We create programs, policy advocacy work, offer help getting farmers to work together collectively. We just filed the paperwork, after working as a group for 2 years, for the Mountain State Co-op!

What we already knew is that our farmers often utilize organic practices. They believe in the tenets of organic and in soil health. We learned that they aren’t necessarily interested in certifying right now due to the expense and the paperwork, and having someone on their farm they don’t necessarily want there. They are not getting a price point back that warrants the additional work on their part. I have my fingers crossed for some action there. We are using the TOPP program to conduct outreach and education about the benefits of organic practices. We have 3 mentees which are part of the Mountain State Co-op group. We are working with New Roots Community Farm and the West Virginia Maple Producers Association. Looking forward, in 2024, we are excited to do more events, outreach, grow our relationships, and introduce a virtual coffee hour. It will include a 30 minute ask the expert time to make this work less scary.

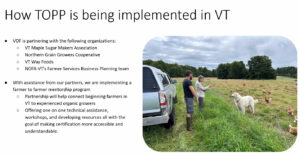

Nicole Dehne, VT with Vermont Organic Farmers (VOF): I’m the certification manager for VOF. I’m here to talk about why TOPP is important in Vermont. Starting to see a decline in number of certified operations. In 2022 saw a 2% drop and expecting a similar decline by end of this year. Some is the organic dairy crisis, some farmers are retiring, so it does feel like an opportunity for TOPP to address. Record keeping requirements mean producers need assistance in navigating requirements. How we’re implementing TOPP – model of partnership.

More maple producers than any other type of farm in VT. With assistance from partners, implementing farmer to farmer mentorship program. Also offering one on one technical assistance to growers all with goal of making certification more accessible and understandable.

Diana: We are grateful for this group and the way we find ways to work together. We’ve watched the TOPP process and across the country. I want to recognize our other regional leads for the way they have been doing this work together. Thank you, too, for our team at PCO and their team effort!

Questions from the NOSB to the TOPP presentors

Allison: There are 3 pillars in organic transition – one of things that is important in regions with fewer producers is financial assistance during transition time – are you getting the support you need to help producers connect with conservation programs and pay them for public benefits they provide.

Diana: We have been talking about wanting more involvement from NRCS. That pillar of the three could be deployed more easily. That’s an active discussion and an area in which we could use more support.

Allison: Farm Bureau came up a couple of times. One positive existing relationship, and others where it could still be built. How could we leverage the relationships that exist to build support within others to reinforce the TOPP work?

Diana: I think that community building is a deliverable. We are all working on that issue. We have to step into spaces not traditionally comfortable or welcome. We are trying to recognize challenge with grace and patience. Any farm bureaus, local or state, we’d love to be working with you.

Dilip: Thank you for your presentations. I have two questions for Dr. Shivers and one for Laura Davis. I’d like to applaud Dr. Shivers efforts working with Black Farmers. We heard yesterday that 98% white and 1% Black farmers in the US. You mentioned that you’re reaching out to the US Virgin Islands. These are very unique. I work with those organic farmers on those islands and I know the challenges they are facing. How are you reaching out and supporting them, which need a lot of help and support in organic production. They really are going through a lot of challenges.

Second question: Are you working with 1890 institutions. They have mandates to work with African American Committees.

For Laura Davis: You teach organic and conventional farmers. How do you motivate them to try organic farming? How do you encourage them?

Laura Davis: How do we motivate conventional farmers? One of things we’ve done is to educate them on little farmers underneath the soil that are being killed by chemicals. We have active microscopes so they can see what is alive in their soil and they get really excited if they see organisms moving and alive. So we start where they can appreciate that and have horticultural growers who have reduced reliance on chemicals and increased biology. By looking at it that way and not attacking on chemical use then they can learn and evolve. Excited about UMass involvement b/c conventional farmers tend to look to UMass about what is going on in the field.

Dilip: Life below ground is very important and plays a vital role in organic farming.

Franklin: My question is related to Dilip’s. Did you encounter attitudes towards transition? Did you learn anything you didn’t expect?

Diana: One of the benefits and joys of working with strong leaders is that anything that comes up we have tackled together or worked on a solution. I can’t think of any particular challenges. Jenny mentioned that our region is socially challenging. Population centers and rural tracts. There have been some honest discussions about demographics and how we support one another. This group in the Northeast has been a joy to be a part of.

Kim: Similar question to Allison’s, talking about partnerships in conventional space. Can you expand on NE grain growers co-op and successes and roadblocks?

Nicole: We’re partnered with the NE Grain Growers cooperative. The biggest hurdle we’re seeing there is the market. Some of that is being addressed by the other arm- market development funding. We are not seeing as many mentees in that area as we had hoped due to that roadblock.

Amy: This was inspiring to hear how TOPP is being executed. Dr. Kaia, I loved how you said farmers don’t want handouts and you mentioned importance of competitive markets. What are top 3 areas we can work on in terms of market development

Dr. Kaia Shivers: a lot of farmers farm I food desserts so they don’t have a market locally. They would like to have more markets where they live. They also need support in terms of getting it to market and processing facilities. Lot of racism in processing facilities – food getting stolen, for example. Need to feel safe where can get food processed. Also need “marketing.” some type of support so they know they are growers and that people know there are black farmers. People thing they don’t exist. And another one, is black farmers need support getting into farmer’s markets and the system in place does not take into consideration the farmers that don’t have Venmo and cash app – push for technical assistance so they can be competitive at farmers market. Fifth, there are row crop farmers so in commercial space I challenge those big companies to reverse how they consider those who grow, meaning they have contracts built out for collectives that are not opening to black farmers so what else is needed is conversation with bigger companies how are they creating something that allows black farmers to compete in collectives or create BIPOC group.

Back to Dilip’s questions:

Dilip: Thank you for your presentation and for reaching out. I have two questions for Dr. Shivers and one for Laura Davis. I’d like to applaud Dr. Shivers efforts working with Black Farmers. We heard yesterday that 98% white and 1% Black farmers in the US. You mentioned that you’re reaching out to the US Virgin Islands. These are very unique. I work with those organic farmers in those islands and I know the challenges they are facing. How are you reaching out and supporting them, which need a lot of help and support in organic production. They really are going through a lot of challenges.

Second question: Are you working with 1890 institutions. They have mandates to work with African American Committees.

Dr. Kaia Shivers: We also work with the southeast region with Florida Organic Growers has a growing relationship with HVCU’s. started index in pandemic so communication was far and few between. We started going straight to farmers. Many have relationships with extensions. HVCU’s severely underfunded and in a lot of legal quagmire. How do we get funding to go directly to the farmers. Needs to be a lot more support. USVI and Puerto Rico – a lot of work done digitally still. USVI has been more represented on index b/c mostly English based organization. Have brought on interpreters. Right now, communication is digitally and one organic grower on USVI – a lot are practicing organic, just needs more support on infrastructure b/c everything costs more. Same thing with Puerto Rico – process is so expensive and cost of living on the islands.

Jerry: Your enthusiasm is infectious. I’d like to note that yesterday, NOC had a grower panel, mostly local. Mr. Spear, a Native American fielded the same question of what do you need… the answer also wasn’t money or a handout, but it was powerfully said. He said, “we need a seat at the table.”

Dr. Kaia Shivers: He said I’m a Native Farmer. I said- second time is divine- what are we going to do together?

Nate Powell-Palm: Describing several colleagues who are binary and black farmers. How do we elevate their voices?

Dr. Kaia Shivers: pay them. I recognize that farming is a business. When you want them to come, pay them for their time. They are always farming or thinking about it. Two, you have to give them a platform how they speak and see things without correcting them. And then there are cultural things – a lot of people tend to look at people of color as being at a deficit. Farmers operate through ancestor and lineage. Before I had inroads, I had to give my family tree. Tend to see same farmers at every function and don’t represent expansive farming community. Want to diversity and what they call farming. Only on record on 2 black-owned farms that own 1000 acres or more. One is fighting for land in Colorado. Plan events around growing system – winter or low months. In Louisiana, we meet farmers at festivals that they grow around. If you can meet them, they will talk, in between that they are growing.

Spencer: What is the Co-Hops, co-op?

Spencer: It was originally around growing hops. 8 farmers to get ¼ acre hops yards up and running. They have already expanded to allow value added producers into their co-op.

Dr. Tucker: Let’s all give a huge round of applause for these speakers!

Livestock Subcommittee (LS)

Kim Huseman, Chairperson

We have nine Sunset Reviews for the Livestock Subcommittee this afternoon.

2025 Livestock Sunset Reviews

All details about Sunset Materials can be found in the NOSB meeting materials [PDF].

Alcohols: Ethanol and Isopropanol

Nate Powell-Palm: I reference back to the panel on sanitizers for these materials. The panel said you need lots of options you can rotate through, so you don’t become too reliant on one santizer. The community says these are both good options to keep in the barn.

Amy: Comment on stakeholder comments: the accessibility to alcohol is good, meaning you can find it everywhere. Easy to use and access, both are important.

Nate Lewis: Do you have any info on the availability of certified organic alcohol?

Nate Powell-Palm: That was not part of the discussion. Note that due to absences, 9 is the supermajority this time for voting (only 13 NOSB members are present).

- Motion to de-list Ethanol. Yes: 0 No: 13 Absent: 2 (Zamora and Jeffrey). Motion to de-list fails.

- Motion to de-list Isopropanol. Yes: 0 No: 13 Absent: 2. Motion to de-list fails.

Aspirin

Kim: Aspirin is a relatively straightforward way to provide pain relief, is easily accessible, available, and well-understood. There were not any negatives to keeping this on the National List.

- Motion to de-list Aspirin. Yes: 0 No: 13 Absent: 2. Motion to de-list fails.

Biologics – Vaccines

Brian: We love these slam dunk kinds of reviews, but vaccines isn’t one of them. Vaccines are critical for livestock health and success of livestock farms. In general, they are quite effective. The issues arise with vaccines made with excluded methods (GMO/genetic vaccines). One reference allows for unqualified use of vaccines, and another regulatory reference is more specific and allows vaccines with genetic engineering to be used but with qualifications. In 2014 the NOSB made a recommendation to only allow GMO vaccines when an equivalent non-GMO vaccine is not available. This recommendation has not been adopted yet.

In spite of important concerns over non-active ingredients and the GMO status of many livestock vaccines, the Livestock Subcommittee feels that the need for effective vaccines is critical for livestock production. Since the 2019 recommendations have not been implemented at this time, the Livestock Subcommittee has adopted the following interpretation:

- This sunset review encompasses the entire class of synthetic livestock vaccines, including those made with excluded methods. The Livestock Subcommittee encourages the NOP to adopt the 2019 NOSB recommendation. In the meantime, our interpretation is that this listing fulfills the requirement at §206.105 (e) for all livestock vaccines.

NOSB member: Can you put that statement in laymen terms?

Brian: Two listings for vaccines. Since that 2019 recommendation has not been implemented, this review says that all vaccines can be used. It’s a matter of practicality and the importance of vaccines. This is a blanket approval of all vaccines. The alternative would be to review every synthetic vaccine GMO or not – or just review every GMO vaccine, or basically saying they are all in a blanket approval. It’s not a great solution but it’s the only thing we can see going forward.

Allison: This is messy when we have an outstanding recommendation. My understanding is that if we were to limit use of vaccines, it would increase need to use antibiotics and pull an animal out of organic production? Is that correct?

Brian: Some diseases that vaccines treat for can be treated with antibiotics, but often it means loss of animals.

Nate Lewis: Many states have vaccine requirements so vaccines are needed to participate in a livestock market.

Unidentified NOSB member: Does this conform to everything else we do. Can we challenge this decision later.

Nate Powell-Palm: Yes.

Wood: Why has the 2019 recommendation not been adopted.

Dr. Tucker: It is on the list as “on hold” because there were other priorities we need to move ahead with. This was not rated that high in that regulatory priorities list.

Dilip: I want to understand that what we are voting on today includes excluded methods.

Brian: Maybe it would help that I explain that the 2nd listing in OFPA specifically says that under excluded methods that they cannot be used in organic EXCEPT for vaccines. There is an explicit exception. The writers realized this was such a thorny issue. For some diseases non-GMO vaccines are not available. Rock and a hard place.

Nate Powell-Palm: The power of this is so important for keeping us going as organic livestock. Farmer representatives, including CROPP cooperative (organic Valley), this is a fabulous bright spot in organic that we said “all vaccines are allowed”. Make sure we never but our livestock are not using the best preventive medicines and makes it easier for certifiers as well. It seems reasonable we won’t but this burden on the certifiers. Understanding the concerns of the community – we acknowledge the 2019 recommendation – but we also don’t want to become the “disease Mary” that defines organic.

- Motion to de-list Biologics – Vaccines. Yes: 0 No: 13 Absent: 2. Motion to de-list fails.

Electrolytes

Brian: Electrolytes are used to treat imbalances that cause severe pain and death. They are essential based on livestock comments.

- Motion to de-list Electrolytes. Yes: 0 No: 13 Absent: 2. Motion to de-list fails.

Glycerin(e)

Kim: Having glycerin as a teat dip as an alternative is something famers say is necessary, with a nod to having multiple options. Through Spring comment, most were very supportive of keeping it on the NL. There was a request to validate the methodology through which glycerin is being manufactured. Certifying bodies responded that their way of validating that the glycerin was natural was that it was manufactured via hydrolysis (of fats and oils).

- Motion to de-list Glycerin(e). Yes: 0 No: 13 Absent: 2. Motion to de-list fails.

Phosphoric acid

Amy: After the spring meeting the NOSB reviewed concerns from stakeholders (possible action items): rise or no rinse, downstream equipment (like milk bulk tanks), material review (to determine issue of inerts – are their multiple products in the phosphoric sanitizer meaning you should rinse? Or no rinse?). There is an active ACA working group.

Kim: The materials working group discussed this material. This also applies to the Handling Subcommittee. The inconsistency with how certifiers would review is broader and applies to all sanitizers, and there are different practices for how they should review sanitizers broadly. The annotation for this listing is verified like any milk house sanitizer, affluent, etc. There was discussion around the livestock and handling listings and how or if to align them, and how and if to fix the annotation.

Amy: We had seven comments supporting re-listing. One from a farmer group said it is essential, needed to remove deposits that cannot be removed. Advocacy groups mentioned Environmental and health concerns. Phosphate pollution can degrade water bodies. There were comments asking for improvement with the listing. For handling, there is a little difference in how the listings are annotated. Stakeholders appreciated the more-defined listing in livestock and hopes that it would carry over to handling.

- Motion to de-list Phosphoric acid. Yes: 0 No: 13 Absent: 2. Motion to de-list fails.

Lime, hydrated

Kim: There are quite a few materials that we will see across the different subcommittees. We will hear about this again during the crops review. In the case of livestock: through the Spring comments, most were in support as it is a necessity for good management practices for livestock. Another tool in the toolbox. One commentor brought up that some uses that may not be intended (like using it as a deodorizer). Something to keep on the radar. When reviewing for the fall, all other comments were directed to crops subcommittee.

- Motion to de-list Lime, hydrated. Yes: 0 No: 13 Absent: 2. Motion to de-list fails.

Mineral oil

Brian: Highly refined petroleum oil, sometimes called white mineral oil. Effective and shelf stable against external parasites which can cause serious animal health problems. This listing is for external use only. There is a second listing for internal uses. It also includes lubrication, usually for artificial insemination. Comments were 3 in favor of re-listing, certifiers noted lots of use by their farmers.

Kim: Is there a benefit to coupling the two mineral oil listings and having them at the same time for Sunset review.

Brian: I think that would be great, which means this listing would be reviewed in 3 years rather than 5.

Kim: We have another example of that with xylazine and toulzine. It would take away some of the confusion by having them go through process at same time.

Amy: Are there any natural alternatives that are out there and effective?

Brian: I’d have to look into TR for that. Lime sulfur is used for similar purposes. It’s good to have a variety of tools and it’s highly effective. There might be alternatives but this is in standard usage.

Amy: Didn’t know if there is market expansion opportunity for other crops.

Nate Powell-Palm: I don’t want to have a dirty mind in the gutter but wanted to note your entrepreneurship Amy. I use this material to do AI with my own cows. I haven’t found a good analog to use.

- Motion to de-list Mineral Oil. Yes: 0 No: 13 Absent: 2. Motion to de-list fails.

NOSB Livestock Discussion: Organic Pork

Kim: I will not be running for chair of the livestock committee next year.

Nate Powell-Palm: Since we’re running ahead of schedule, mention swine production – we have a chance to think about other areas we could bring to light. Putting it out to community that I don’t see where the market is yet, calling for organic pork, or do have a lot of farmers that want to grow it. Who are those organic pork buyer or brands. It’s easy to round up farmers to tell us best strategies, but we need to know there is a market when we get folks to transition.

Kim: We had robust conversation in LS regarding swine. We altered our research priorities and it now includes swine production. I’d like to encourage land grant universities to figure out ways to put dollars into research. No only from buyer aspect but also challenges of swine production in organic format. It’s a holistic process: yes, you have to have buyers but what comes first? So many challenges in this space.

Carolyn: As part of organic swine conversation, have to consider processing capacity. The whole entire food system rather than just the two end.

Brian: anecdotal comment – our local super market always has organic bacon. For many years had organic ham for cold cuts. I don’t see why there wouldn’t be an organic market for hams, bacon, and sausage. Quality that we can get when it’s available is very high.

Wood: Why would there not be a market for this product? Amazed by comments on this.

Nate Powell-Palm: There is a cooperative working on a pig pool. Folks are trying to access markets. As inspector inspected 1 maybe 2 organic pig operation out of over 3000. How does organic hog grower access middle production point.

Carolyn: What happens to the rest of the pig f you end up with bacon in the store.

Kim: Organic casings!

Nate: Put on the table the aquaculture and wild caught seafood standards.

Nate Powell-Palm: Reconvene tomorrow with CACS.

END DAY 1.

Wednesday, October 25, 2022: Fall NOSB Meeting, Day 1

USDA Risk Management Agency: Risk Management Agency (RMA) presentation

Francie Tolle, Director of Product Administration & Standards Division

Dr. Tucker: Introduces Tolle. Joined RMA in August 2015 as Regional Office Director in Oklahoma City. Previously served at Oklahoma FSA and as policy analyst, and others. She was named 2000 Oklahoma Ag Woman of Year. Native of Oklahoma, she farms with husband, and now raising 7th generation on a farm. We collaborated on how we get transitioning farmers under our framework by having them listed in OID to provide on-ramp for transitioning farmers to be in the system and acknowledged by RMA.

Francie Tollie: I have been on farm all my life. One son farming full-time. Going to hit some high level areas of crop insurance and the report that came out that you guys will discuss. Hear crop insurance doesn’t work, but not specifics of why. At RMA there is a big desire to bring everybody in crop insurance program. No reason we should not. If you are farming it’s incredibly capital intensive. Crop insurance helps farmers sleep at night, way to get a loan. It’s important for everyone. Trying to work through this very important. Will hit high points and what’s in report – this is just first conversation we’ll have.

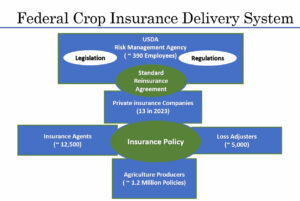

Federal Crop Insurance Delivery System (slide): We work different than other agencies. We have 390 employees, small, and our delivery system though is very large. Improved insurance providers (12 in 20223) and they have agents they contract with (5000 adjusters) and they work through insurance policy with the producer. We have the largest safety net, but smallest agency. When we look at what implement, we look at legislation and have authority to develop programs. Some insurance that’s been out awhile are codified – so when we do a regulation it’s because producer group has said want to change the policy. Crop insurance is the same price for producer wherever you go. This crop insurance or that gave better deal – no they didn’t — it’s same wherever you go. What may be different is agent may be offering different options, different coverage areas. Competing on service – how well can service producer.

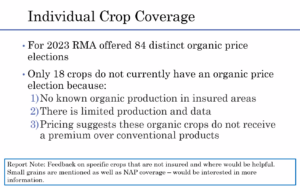

Individual Crop Coverage (slide) Number 2 in this list is the biggest issue and mentioned throughout report – where do we get data and how. People bring it to us, NAP program is where can get coverage up to 65% = not required to be actuarially sound. Producers purchasing NAP – we can’t insure it – but we can go get data there. Sometimes we get data from producer groups. Not a set amount of data need, but do need multiple years, maybe a county, but the more producers can get in an area over several years is more helpful. Also look at proxy crop that yields similarly. In the report one producer mentioned small grains not insurable in area – they should be and if not, we want to look and see where this is happening. Written agreements were mentioned – involves more paperwork, but that is how we expand.

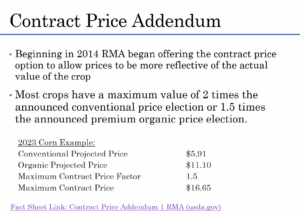

Contract Price Addendum (slide): Brought about to get to a price that is more comparable to what price is for organic. Usually 2 x conventional price (see slide for calculation).

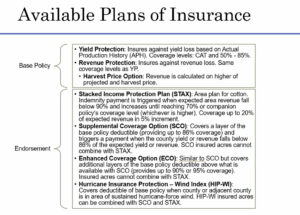

Available Plans of Insurance (slide): Generally 50-80% coverage level – means that if farmer has 70% coverage then 30% deductible. There are various endorsements that help fill deductible and generally area type plans based on the county. Endorsements shown on slide – producer can get up to higher coverage levels.

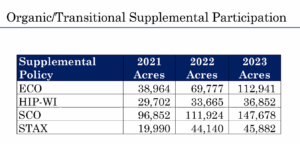

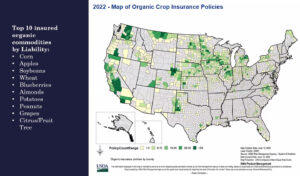

Organic/Transitional (slide): These policies have grown from 2021 – 2023 as shown on slide. This is how producers can get to higher coverage levels. I farm in Oklahoma and it’s expensive.

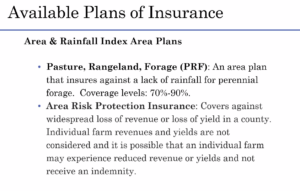

Available Plans of Insurance (slide): We added Organic and Transitional Practice to PRF. Area plans, instead of individual, you can look at county wide policy, but it doesn’t necessarily follow what happens on your farm. Lots of different options.

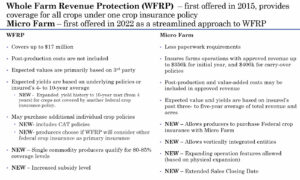

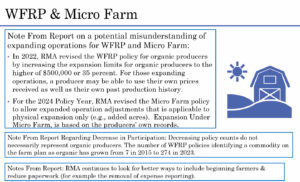

Whole Farm Revenue Protection (slide): First offered in 2015 and microfarm in 2022. Both cover all crops under one insurance policy. IF there is one that is not able to be insured individually, this might be a way. We made a number of new provisions for 2024 and most came from talking to producers and agent feedback. Extended sales closing date- that’s one agents said if had more time said it would help so we extended closing date by 30 days.

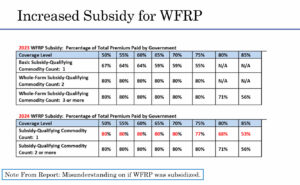

Increased Subsidy for WFRP (slide): Previously if only had one crop that you had whole farm policy – say sweet corn – only crop you had – you were not eligible for 80-85 percent coverage, now you are. We also increased the subsidy level. If 2 or more commodities then subsidy is a little bit higher. Generally for crop insurance program is 62%.

WFRP & Micro Farm (slide): There are expansion provisions in whole and micro farm. The expansion limits based on own production and pricing. Also reference in decreasing participation in whole farm, and in last couple of years when prices so high, dropped out. For organics specifically, there were 7 in 2015 and 274 in 2023 so that part is growing. Hope we can make whole farm more appealing. Agree need to include beginning farmers and ranchers. What do you do about history? A few ideas want to work through. Tried to reduce paperwork too.

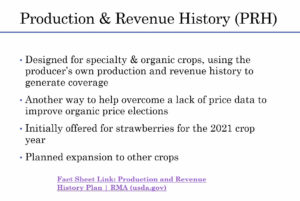

Production & Revenue History (slide): Initially offered for strawberries – looking at other crops now due to demand to expand the program. This is a new pilot. Helpful to get feedback about what works and what doesn’t.

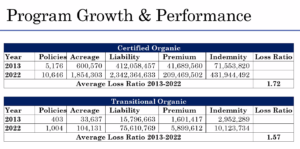

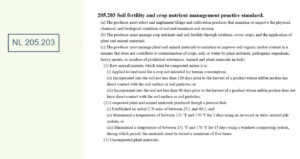

Program Grown & Performance (slide): Number of policies have grown significantly. Report talked about loss ratios and they are not good. You at least for every dollar want a dollar coming back. Shouldn’t be any higher than one. Entire program is looking at loss ratio of one and also required to have reasonable reserve. At about .88 and this is a struggle. Producers talk about T yields being too low and looking at this they are actually too high. If want specifics on loss ratios then go to website. Want to give producers as much info as can.

Map of Organic Insurance Policies (slide): Darker the color the more policies there are. Any time have producer does something that works, the more that come on. The more successful organic farms we have the more people will want to get involved.

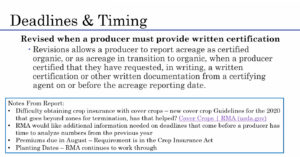

Deadlines & Timing (slide): We revised when producer provided written certification. Now we require you show in writing that you have requested that. Other notes from the report – we would like to hear more about difficulty obtaining insurance for cover crops. Zonal guidelines and published materials for area saying this way cover crops can be terminate or third way have ag expert saying this is a good way to terminate cover crops. This can be brought to agent. Don’t know if this has helped – if get ag expert on a new way for termination – asked how that works, but never seen it done. Also comment about deadlines that come before producer can analyze numbers for previous year. Legislation mandates premiums due in August. Planting dates – regional offices look at this and take data and look at plant dates and indemnities. We need to see planting later and yields going up. We’d like to allow planting dates later. Hopeful there will be something we can do.

Other Efforts (slide): We will come back. For sake of time, to take a short break [to hear some news from the U.S. Department of Agriculture Under Secretary for Marketing and Regulatory Programs Jenny Lester Moffitt.

Dr. Tucker: [Introduces Jenny Lester Moffitt.]

U.S. Department of Agriculture Under Secretary for Marketing and Regulatory Programs Jenny Lester Moffitt: Vilsack will be announcing the final rule of OLPS. This is a really exciting occasion. This has been a long time coming. Thanks NOSB and leadership, more than a decade and the NOP staff. Exciting time and many in room knows what this means. We are continuing to improve. This is what rulemaking and tenants of OFPA is about. OLPS final rule is another example of that. These rules are part of continuous improvement. Will establish clear standards for Livestock and poultry products. Greater outdoor access for healthcare, transport and slaughter. More consistent standards for outdoor space. Preventive healthcare, transport, handling, making sure all producers are in fair market. Consumer confidence has continued trust with USDA organic seal it means what they think. Implementation timeline, there are many pieces, at most 5 year implementation timeline for furthest. Over 40,000 comments and thanks industry and everyone who provided feedback. Secretary is hopping on press call at 11:00 today. Chair Powell-Palm will be on that call. Exciting day for organic industry, NOSB, NOP. This is about leveling the playing field, making sure we have and maintain rigorous organic seal consumers can trust.

[The presentation returns to the RMA discussion.]

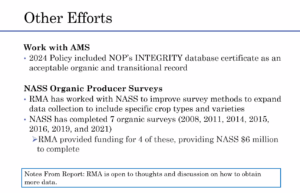

Francie Tollie: We can identify transitional – one of challenges is that I’d like to think everyone in crop insurance program is completely honest – we don’t want to have producer who is out there when input costs so high, saying didn’t apply chemical and get a crop insurance indemnity. IF loss ratios go up, becomes more expensive for everyone. Some other efforts – we have funding last 7 organic survesy with NASS. We provided 6 million dollars for them to complete surveys. Any ideas you have for us to get more data we are open to.

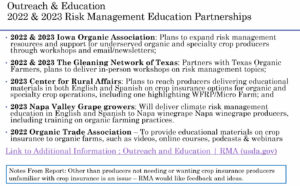

Outreach & Education (slide): I pulled up a few that identified going to work specifically with organic producers. Reasons for not having crop insurance often is don’t know about it. It’s the people that know what’s going that help us move the needle.

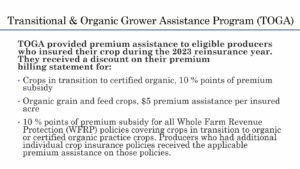

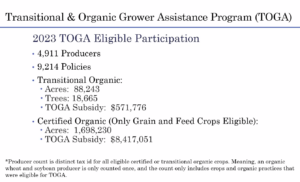

Transitional & Organic Grower Assistance Program (TOGA): offered additional premium assistance – 10% for crops in insurance. Additional information on slide.

TOGA (slide): some producers have more than one policy.

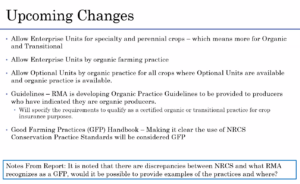

Upcoming Changes (slide): enterprise units way of insuring by pulling all farms together, premium discount so makes crop insurance more affordable. Also looking at enterprise units for organic farming practices and looking at offering more optional unites to tailor to farm. Request for guidelines on how crop insurance works for organic – working on these and going to be asking for feedback. Good Farming Practices Handbook – when we say good farming practice, lets say you are producer and have a claim and loss adjuster says you didn’t follow good farming practice. Producer has right to appeal and say did follow GFP. They provide information about the practice and why did what did. Regional office will decide. When say GFP it isn’t a simple thing, it’s a process. If you have specifics on discrepancies about what is a GFP, let us know, especially if NRCS practice.

RMA.USDA.GOV (slide): Get to know your regional office – there’s info about t-yields, planting dates, and other tools.

Questions & Answer: NOSB questions about RMA

Dilip: I work with local and regional RMA office in TN and very helpful. You showed a U.S. map with green dots and I notice some states have more and some don’t. What’s the reason and what can be done? The second, can you tell us about vertically integrated entity on microfarm?

Francie T: Map shows where we have organic insurance policies. The darker the green, the darkest have over 50 policies. A lot of reason, if farmer has successful farmers around, and so once get people talking about it and doing it in a way that is successful for producer and organic community, that helps spread. Crop insurance agents – where there are none. If I talked to my agent they would have to research what to do. I want to be able to provide you guys with enough info. IF I were you, I would take to my agent and say this is what I’m looking for and I need your help. Most will try to help you, but it’s an education process for agents. We’ve tried to step up the training for agents. Guidelines I talked about that will be provided to agents and producers is way we’re trying to make clear this is what you need to be doing. This is my speculation.

Dilip: 2 cover crops council and you were asking about more data. I would add these two councils could assist. They can work on this data issue.

Francie T: Microfarm previous to this year, we didn’t allow Vertically integrated entities b/c ensuring up to $350,000. Didn’t want to see large entities break up and apply for microfarm. But then decided there were enough legitimate requests that we did it. We’ll monitor it.

Allison: Heard that in Texas it’s hard to find whole farm policies so if no one offering policy what should they do?

Francie: One, they should be offering it. Some agents are more familiar than others. They all should be, but if someone can’t find someone then contact regional office and see if we can help. Or email me.

Allison: Some slides had acreage, policies, operations participating. Increasing in acreage and operations or how since of how breaks down?

Francie: Whole farm is just one way can insure operation. Program has grown quite a bit. How many of these policies are whole farm versus individual – is that your question?

Allison: more operations taking advantage as acreage growing or similar number of farms but more acreage?

Francie: If I’m growing 2 or 3 different crops then more than 1 policy. One producer might have more than one policy.

Allison: Question about the growth in acreage slide.

Francie: These are supplemental policies. Might have policy for corn, individual policy, might buy 70% coverage. 30% cover yourself. The supplemental policies provide opportunity to fill that gap up to 90-95%. These are not for whole farm, but individual crop policies. If I were guessing I’d say this is going on in Midwest.

Allison: Acres correlate to number of operations?

Francie: don’t have that data. We’ve got various options for transitional and organic farmers. If need for that data, we can pull that for you.

Logan: Why is the loss ratio greater in organic than transitional?

Francie: More losses.

Logan: Saw that loss is higher in organic than transitional.

Francie: You’d have to look at crops and location and don’t’ know right off if same place, weather events, if indemnities based on weather event and where. Have to do deeper dive to see why that is. Ths is the most challenging for us. We don’t want to rip carpet out from under.

Logan: when do you identify when transitional?

Francie: by acreage reporting date, you have to show you have talked to a certifier and in process of doing that.

Logan: things would be like what seed are you planting, etc.

Carolyn: New guidance for crop insurance agents – how are you measuring efficacy of those? Will you give agents a test? How do you know it will be used?

Francie: we’ll be asking them as part of compliance reviews. We have requirements that producer is supposed to be provided.

Carolyn: What is a compliance review?

Francie: 2 different things. RMA has a compliance division. When they go out and look at AIP from agent to producer – they are reporting back findings to RMA and expect them to make changes if procedures and policies not followed. RMA – compliance is about 1/3 of the agency. Regional offices are looking at how things are working. Product management is another 1/3 and we are looking at how going to change things.

Carolyn: You would expect to see more organic crop insurance policies? How measure success?

Francie: Not sure that’s the way to measure success. Better measurement would be to look at partners and see if message is getting out and are people requesting crop insurance. Is survey in study moving needle. Are people more aware of it – get producers familiar with it. Regional offices out there talking to producer groups. Guidelines are not going to be a good measurement.

Carolyn: Thinking about climate events. How will RMA weather that? These problems will become more severe. Do you just take every year as it comes?

Francie: different practices that we look at, different crops, ones that don’t require as much water. Different practices available so those are kind of the things we look at. Still heavily dependent on data. Had pandemic cover crop program – funding only for 2 years. That’s a way for us to collect data to see if different practices are helpful. there’s a lot of little pieces but no silver bullet.

Kim: Can you expand on RMA and NOP collaboration?

Francie: Keeping open dialogue – looking at how we can work together. Best way to describe is to keep in continual contact. Jenny may hear about an issue and want to know what’s going on. Relationship very important.

Kim: Can you go back to slide that shows levels for corn and as talk about transition is there any thought about price factor for transition?

Francie: No, but if you have suggestions we will listen.

Kim: think that is another gap worth noting and gives us something to work on.

Unidentified member: can use contract price addendum. Nice intermediate solution right now.

Nate: losses due to pesticide drift and often misapplications and out of luck with RMA. Also seeing trace amounts in rain water and loss or organic premiums through export. Avenue where can bridge gaps in coverage due to loss of quality?

Francie: not at the moment. One of hardest things to deal with – pesticide drift is one of most difficult things deal with. Even conventional farmers are asking this. Problem is it starts man-made. How do we deal with this? With what you just said are you losing certification or quality?

Nate: both occur. If someone misapplies can usually get indemnity for loss of that year’s crop or up to 3 years if lose certification. But not all states like Washington. Case specific, is it glyphosate or flame retardant, its all across the board and trying to explore ways we could create a national approach b/c state by state is not working. Insurance coverage seems to be the logical tool. Probably is an act of Congress issue at this point. Just curious.

Francie: difficult and different problems with different producers. National approach would be interesting. Different states have different laws. Need some help thinking about this.

Jerry: slide that has U.S. shown b/c it’s way too geographically specific not to give more info than getting. I see 8 geographic clusters that indicate to me crop types. Are there crop types that find this program more beneficial?

Francie: It would be interesting to overlay that. I will tell you conventional farmers that transition are most familiar and first to get crop insurance. Specialty crop producers not as familiar.

Kyla: How to verify transitional claim? ACA did work to create pre-OSP. That tool along with a memo to utilize integrity database – these should address how to verify those producers.

Francie: I hope so too. Memo was several months of work. Also realize more work to do. Would welcome feedback.

Kyla??: quality issue – there are standards for losses in quality, but doesn’t kick in until grade 4 or 5. why we get contracts b/c we get grade 1 or 2 type quality. Could there be a quality metric so it matches contract. There is a purgatory zone where grade 4 starts kicking in for quality. I’ve talk to corn board about this b/c know conventional producers could be in similar situation.

Francie: for food quality for organics, I think we’d be looking for what are those quality levels that we could set in the policy. factor should probably be more regional. When there is a weather event, warehouses or delivery points – quality changes and doesn’t fit national quality. A long time ago if below quality then that’s what would pay. Then elevators started listing insurance and non-insurance price. So where do we get the quality standards. You’re bringing in whole other area – don’t’ know where we get those quality factors. If anybody can help would be great. Big issue. Not the same for everyone. If have ideas we’ll listen.

Compliance, Accreditation, & Certification Subcommittee (CACS)

Amy Bruch, Chairperson

Discussion Document: Organic and Climate-Smart Agriculture: Climate Induced Farming Risk and Crop Insurance

Carolyn: Discussion Document: Going to talk about next steps. RMA is making changes and Francie identified where wants more information. Specific evidence to back up discrepancies. I’ll listen to the transcript. Where do we go from here with this document? I’ m curious what are good next steps.

Allison: A few areas RMA wrestling with. One area that stood out is how to demonstrate producer is in transition that insures not fraud and sounds like some sort of interaction with certifier is what RMA is looking for. Maybe transitioning producers involved in TOPP or buying compliant seed might be other factors that look to. Another was appreciate Francie’s openness to feedback and how can we make that accessible to producers – maybe one point of contact where producers can go to address challenges.

Nate: imagine crop insurance will continue to have challenges. Not going to clear it all up with one document. We could lay foundation for future boards. We can help synthesize conversation for future boards.

Amy heard a lot of comments from producers; invigorating to know we can find solutions. On the short list, I’d like to see if we can advance some of those items, stress test them and push community for solutions that could advance solution oriented outcomes. We labeled 5 or 6 of them. Maybe pick a couple and make progress.

Nate Powell-Palm: how we can be more organized in getting data sets to RMA. Question to community, if any existing infrastructure to get data.

Carolyn: What kind of data would be statistically representative enough for RMA purposes?

Francie: university data, and the more producers the better, multiple years and again if you identify proxy crops we try to work with those as well to get similar data. Not hard and fast rule. Doesn’t need to be federal data, but just well-documented. A producer’s own production and if have delivery point and that delivery point can get data, then that works.

Discussion Document: Opportunities in Organic – Improving Support for Organic Transition

Allison: Transitioning means bringing more land under organic management. The discussion document outlines attention to transition including 300 million investment. TOPP program, direct funding ,and crop insurance discount, and also market development grants. There are barriers to transition noted in document. WE have ability to gather feedback to improve upon what’s already in motion. Asked community 5 categories of questions (see slide). we received thoughtful comments

High level categories are: Role of consumer demand. reducing cost of certification. relationships and trust. getting out of our circles. I would love to hear your thoughts:

Nate Lewis: One of the areas that has come up to me from OTA experience “asking anything” is back to language and what we use. When folks ask questions of certifiers there is a reticence to use certain language to not cross line of “overcoming barriers to achieving certification.” Example: How big does my buffer need to be?” The certifier gave a vague answer. IF we could decide where the line is and share a recommendation that could help certifiers develop that rapport with aspiring and young farmers.

Amy Bruch: Thank you Alison! The commitment from the community came forward. One organization provides price increase for transition producers. There’s not an official transition market, but some companies are willing to invest in transition producers because they want to work with them when they are organic. Walking with that producer the whole way is important. Retention is also something we heard through public comments. Once we gt these producers to transition, we need to also solve challenges current organic producers are facing. Markets and maintaining organic integrity.

Nate Powell-Palm: Trying to be more helpful. I see a world where organic inspectors cut their teeth with 100, maybe 1,000 inspectors and then become consultants and help people get certified. Find a 17 year old who can read, show them how to teach reading, and send them out to spread literacy. We need folks to go out and make it easy so farmers can farm and not be regulatory experts as well.

Carolyn: You triggered in my mind- through my research I found that farmers in transition find the inspector to be a primary source of information. IS it true that the inspector is not allowed to give information?

Nate Powell-Palm: If it’s publicly available information, it’s within bounds. “How should I fill out this form?” Would be overcoming a barrier to certification would be consulting. Filling that gap is the next step.