Join The Cornucopia Institute as we keep you informed via web updates from the National Organic Standards Board (NOSB) meeting online.

We will be sharing the play by play of the meeting on April 29-30 and May 1 below.

For background on issues up for discussion at the meeting, see:

- The NOSB’s Proposals & Discussion Document for Spring 2024

- Cornucopia’s oral comments

- Cornucopia’s notes on the oral comments for the Spring 2024 NOSB meeting

- Additional information on this meeting and past meetings dating back to 2012

APRIL 29, 2024: Day 1 of the SPring 2024 NOSB Meeting

Call to Order made by NOP staff along with some welcoming remarks. Secretary Randy Romanski is then introduced to give some welcoming remarks.

Secretary Randy Romanski – WI Dept of Agriculture, Trade and Consumer Protection (DATCP)

Career public servant in WI. WI are known as America’s dairy land. Take advantage of sampling food in the area. Wisconsin – 104.8 billion dollar industry. Produce about 50% of U.S’s specialty cheese. Also export a lot of it. Top 5 producers of many commodities. Number 2 organic state in the U.S. According to 2021 Certified Organic Bulletin, from NASS, we have 250,000 certified organic farmland. First in certified organic cranberry production. Produce 23% of organic goat milk. AG of all types is important part of state’s economy. Share your stories as people get more and more removed from the farm. Important to know where food comes from. As agency, we are resource to the industry from farm gate to dinner plate. Provide regulatory and resource component. The process works best when everyone working together. Through organic cost share, advisory counsel and grant programs we connect public with consumption of organic products. Advocate for comprehensive farm bill. WI, like other states, have consistently been advocating to get a farm bill done and that it is well-funded. Head of state agency and times when ask legislature for resources. Partners at USDA need resources to make the connection. Also need to make sure we keep feeding programs, investing in research, a lot that needs to be done in Farm Bill. Fortunate to work for the governor who understands and invests in agriculture. He has consistently supported all levels of ag – all types, all sizes. Through his leadership we have increased investments. Important as we look forward. No matter where from or part of industry or how connect with growers, you’ve got a lot to be proud of. Feeding the world is important. Share your stories. Close on one thing – being aware of each other. Even in good times, food production is tough. Changing weather patterns, challenging markets, and volatile prices have an impact and that can be a lot. Important we are providing resources to farmers. WI Farm Center has been that partner. Provide a variety of resources. Added new programs that tend to end with b/c know other states have them and that’s farmer mental health and wellness programs. Farmers should have a resource or place they can go – if struggling with hardships, depression, we have a 24/7 hotline. Encourage people to share the number. 888-901-2558. Many states have similar programs, it’s important resource our agency makes available. Thank you.

Agenda Overview

The agenda can be found here.

Introductions

Jenny Tucker does NOP staff introductions (passing out candy to people!). Tucker thanks the staff for their work prepping for the NOSB meeting.

You can find more on resources to contact and see the current NOP staffers here.

NOSB Introductions

Kyla Smith (Board Chair) introduces the NOSB members and has them give a short background about their work on the NOSB. You can find a current list of NOSB members here: https://www.ams.usda.gov/rules-regulations/organic/nosb/current-members

Amy Bruch and Logan Petrey joining via Zoom.

Kim Hussman: Handler’s Seat. Superior Senior. 5th year on Board. Background on poultry feeding and organic oilseed crush and oils and protein products.

Nate Powell-Palm: Sits in producer seat. Is a beef/cattle producer from MT.

Dulip Nandwani: Completed 2 years on Board and serves on scientist seat.

Franklin Quarcoo: Environmental resource conservation seat; work at Tuskegee Univ

Nate Lewis: WA farmland trust; chair policy dev subcommittee and secretary

Allison Johnson: Public interest seat; attorney for Natural Resource Council; Oakland, CA

Brian Caldwell: Consumer public interest seat; retired from Cornell; researched organic farming. Certified organic fruit and nut farm. Certified since 1986.

Jerry D’Amore: Monterrey, CA. Handler seat. 51 years in food production/sales – hydroponic systems; resident in various countries; last 20 years devoted to go-to market side

Carolyn Dimitri: Consumer/public interest seat.

Wood Turner: Environmental designer and planner; last year on board; produce organic blueberries; also planning to transition NC farm to organic

Mindee Jeffery: Retailer seat. Background in compost!

Amy Bruch: Farmer seat. Serve as vice chair an chair of CACS committee. 4th year on the NOSB. About two decades of experience working in production ag and consulting farmers to transition to organic.

Logan Petrey: Farmer seat. From Southeast and in 4th year on the NOSB.

Kyla Smith: Certifier seat. Certification policy advisor at PCO. 4th year on NOSB.

Secretary’s report

Nate Lewis (Sectretary): Any corrections on draft report? Meeting minutes accepted.

NOSB Report

Kyla Smith: [Describes her background and why she is dedicated to NOSB work, including her experiences at the certifier PCO. One difference to working for PCO is being in the public eye. Asks that we work hard to stay engaged in rulemaking process. Notes that the NOSB has a call for NOSB member nominations – people can reach out to NOSB members to ask about the time commitment. Also notes that we will be having in-person public comments this afternoon (which hasn’t been done in many years.]

Amy Bruch: [Welcomes everyone and gives comments and introductions asking that essential positions are filled in the NOSB (and the NOP).]

USDA/AMS/National Organic Program Update

Jenny Tucker: Introduces Erin Healy (Standards Dir) who will give overview of retailer toolkit. There is an ongoing need to educate people about what organic means. Congratulates on the work done to create the rules and educational materials.

Erin Healy: The label landscape has become confusing for consumers. For someone who doesn’t work in industry, it’s very confusing. Distrust among consumers. Don’t know which label to trust. Looked at consumer research, particularly around organic label. Four people worked on this – recognizes individuals. Worked with Consumer Reports and they did a phone survey of 2000 people to ask about organic label. Turns out only 55% knew organic food is produced without chemicals and only 40% knew organic inspected regularly. (See slide). OTA has come out with consumer attitude report and some numbers are higher, but these numbers show we have work to educate consumers about what this means and why organic is special. Almost 50% didn’t know seal is a government backed label. OTA released findings and better than consumer report – 70% understood products produced without chemicals and antibiotics. Heard through multiple meetings that there is a need to educate consumers. Put together tool kit for retailers. End audience is consumers. If working with retailers or organic brands, helpful.

The toolkit is a variety of graphics that can be printed and used in retail locations or social media (by brands). All of the materials focus on the 4 pillars of organic: protected by law, inspected by experts, traced from farm to store, shaped by public input.

Protected by law: Only gov’t backed label on the shelf. Backed by federal regulations; can levy fines and penalties and put people in jail. The seal is now trademarked; can take enforcement action if anyone is fraudulently using the seal.

Inspected by experts: Infers the unannounced inspections and testing that happens. Used “experts” because we were trying to use plain language for regular consumers. We didn’t want to use words only this community is familiar with.

Traced from farm to store: Refers to the SOE, which gives us the authority to audit the entire organic supply chain at this point.

Shaped by public input: Wanted to talk about our public-private partnership. Twice a year we hold a public meeting, and anyone can make a comment. And when we write our proposed regulations, anyone can make a comment, and we read through every comment.

Some examples on the table outside that you are welcome to take – freezer cling, aisle banners, banners that can be hung from ceiling or above organic produce stand, shelf tags that can be used to highlight different types of food. Used rule of three – didn’t think anyone would remember more than three bullet points. These aren’t going to be perfect, and I’ve heard some input about how we could have done them differently. Big picture and high level to be understood by consumers.

Here is the toolkit which can be used freely by retailers and others to educate about the facts of the Certified Organic program: https://www.ams.usda.gov/sites/default/files/media/NOPRetailerToolkit.pdf

We need brand ambassadors – we need people to speak highly with the organic label. Please tell people about this toolkit. Let people know we want to see this in stores and help organic producers earn more money.

Many graphics also include a QR code that links to the Understanding the Organic Basics webpage where consumers can learn more about the NOP and the organic.

QUESTIONS from the NOSB:

JD: The document that you refer to – USDA organic as administered or sponsored by the OTA – is an extraordinary document. I’ve been around for a long time, and in my 7 years of running Driscoll’s marketing, I had not seen anything that was as heavily persuasive. I do not know why everyone didn’t go out and do a victory lap when that came out. Our biggest problems as an organic group are that we do not talk a common language, and we do not celebrate the same victories.

EH: Stores can insert own branding. Might see this in slightly different varieties. Want consumers to keep hearing about the 4 pillars and QR code to go to website.

NATE POWELL-PALM: When we encourage farmers to participate in this process, often we say that you might not see it, but your voice does matter. In spring 2022, we started hearing more from producers saying that we need to brag a little. I think this was one of the most satisfying opportunities for the Program to hear the community and act so rapidly. We had farmers saying thank you, and I want to thank you, too, Jenny.

KYLA SMITH: Landed differently for me, but then to touch and pick things up – this is great.

JD: How we collectively look at seal along with 20 other pieces of paper – a lot of info in that too.

WT: Drafting off what Jerry was saying about the numbers; what do you think success looks like in this Program, and how is the Program going to measure this over time? Is it retailer adoption, or what does that look like?

EH: I would be elated if see this in a store one day. It starts somewhere. Mom’s has already said they want to pilot test it. Having conversation with Target, Walmart, Sprouts and they are talking about it internally. We want to keep track of how many companies and how many stores within companies are using this. Also tracking online hits. Run a monthly report on that. Most important is getting the message into stores and have them use it continuously over time. Was in Whole Foods, saw TVs, and talking to them as well. Need everyone’s heLogan Petrey to connect with retailers.

AB: Thank you for working on this. Incredible. We have such a good story to tell. Organic program fires on many different cylinders, and to create such a succinct, digestible message is great.

Jenny Tucker: [Continues with NOP update.]

First, welcome to our organic farms and businesses. 1,667 organic farmers and businesses in WI as of last Friday. I was not surprised by this number. As I was typing the number into the screen, it reminded me of the enormous responsibility that this Board has. The Board is representing not only the farms and businesses in the room, but the 35,000 organic farms and businesses around the world.

Part 1 is online in the Organic Integrity Learning Center. Robust update. The Insider that went out last week has a direct link to that presentation, and I encourage you to take a look.

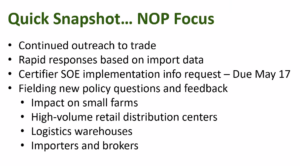

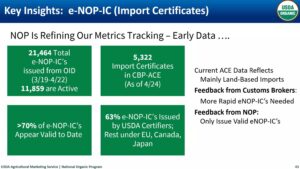

Topics I will be covering in Part 2: SOE update (80% of presentation), briefly review call for nominations for NOSB (which published today), quick updated on TOPP and Transitional Production Plan, and close with an award.

SOE: We have increased the number of certified entities and requiring the use of electronic import certificates, and we have strengthened oversight of certifiers. We are including business that are new to the Organic program. We have to be more clear what “certificatres” are – two kinds now, import and operation level certificates (Are you certified organic?).

ENOPIC – Electronic NOP Import Certificate.

This is really the import protection side. We talk about the number of certified operations and filling gaps, and the import certificate is the absolute top.

I want to review where we are with the import cert. Left side – US importers must be certified organic and must be overseen by a certifier. This is an area where we’ve gotten a lot of push back. Why should I have to be certified if I’m only dealing with packaged products? Well, real-life example. Wine industry. We’ve gotten a lot of emails from wine importers. Why do they need to be certified to bring in sealed wine packages and then sending them off? Because it’s really important that importers help make sure these products are compliant. Within 1.5 weeks of the SOE being in effect, we started to realize that there are wines being brought into the US with sulfites in them. The EU allows sulfites, but under our agreement, we do not allow it.

Under SOE importers are responsible for checking that. Importer needs to understand the equivalency arrangement to make sure compliant with trade arrangement. IF certifier you’re making sure organic system plan captures that check. We’ve learned that customs and borders protection – how view importers. Customs has opened our eyes to that its importers who is accountable for that product coming in. Ultimately importer is responsible for organic integrity. Having importers certified is absolutely necessary regardless of packaging. No way we can go over every box of wine, but when have that effort distributed across certifiers, then when we have conversation with EU, we put this problem at the top of the list. We need EU to be working on this not to send this product over. This is real time impact of SOE within couple of weeks. Exporters and handlers must be certified to get the electronic export certificate. We have heard from customs brokers who have denied entry b/c no evidence product was organic. Three weeks in this has happened. Certifier over exporter and handler issues the certificate. This is certifiers also under trade arrangements – EU and Canada sending the most products. Let’s keep the landscape – tremendous amount of potential. We are concerned about all things doesn’t do, but this is a strong rule and gives us a lot of tools. Let’s see the immediate wins, some will be longer term.

On the right side, exporters and certifiers must be certified. You must be certified to the ENOPIC. We have some certifiers who have denied entry of products because there was no evidence that the product was organic. We are three weeks in, and that’s happened. One of the complexities that we are dealing with here is that this is not only USDA certifiers. EU and Canada are the ones who are sending us the most products. I want us to all keep in mind the landscape of how all of this works. I think that SOE has great potential. I know that we can focus on all of the things that SOE cannot do, but at one month in, I’m convinced this is a strong rule that gives us a lot of tools. We have some immediate wins. A lot of the wins are going to be long term.

Send a certification request to all of our certifiers on how to manage this in a sound and sensible way so that we are not overburdening small farmers. This rule is supposed to help, not hinder.

We are also getting a lot of questions from high volume retailers. We are getting a lot questions from businesses that have not been part of this in the past.

Numbers:

- At this point, NOP has sent more than 700 letters to importers that need to get themselves certified.

To me, that is the critical path. Once those producers are certified. It is working. We’ve made a whole lot of progress.

- Almost 1,000 US Handling operations certified between January and April this year. Comparing year-to-year, that is a 3.5 fold increase. Of the 989, 640 were certified in March and April.

We have had people wait until the last minute. We’ve seen a bit of a process where people do not think they have to be certified – grieving process – but they are getting to acceptance.

- Approximately 1,800 new handling operations worldwide. That means that some of those exporters that needed to get certified are getting certified. We are filling a lot of gaps here.

We are making progress. Many of the 700 are actually in the progress of getting certified and working with a certifier. We do have folks still in denial, but we have a process to track and escalate these to ensure these folks finish certification or get out of the market. Right now, it is looking like we have a 2-6 month timeline for certifications because of the complexity.

Let’s turn to the import certificate. Amount of data is enormous. We have never had access to the kind of info we have now. We can talk about the real time, the data – we have already stopped non-compliant product from entering the U.S. It is very had sometimes to communicate the presence of absence – the lack of fraudulent product. About 21,450ish total import certificates. Of those about 12000 are active (in process or in range of time allowed). There have been some where certifiers screwed up and it’s invalid or certificate has bee used. 5332 entered into the ACE system.

Again, some of how we proceed with enforcement and oversight is going to depend on the volume. We are going to have to make sound and sensible choices. We’ve never had this kind of data to look at what is coming in.

At this point, more than 70% of import certificates look valid. With something this big, I’m going to take that as a win. This data only reflects electronic import certificates. It does not represent those that might be paper based. That is an example of something that might be within that 30%. It’s not necessarily an invalid product, but it’s something that doesn’t have an import certificate in the system yet.

About 63% of import certs have been issues by US certifiers, the rest have been issued by EU and other countries. Current data in CBT are mostly land-certificates right now. Many of the active certificates may still be ship-bound, there is a delay as we have the global throughput successful. We can see that in the commodities: avocados from Mexico or berries, because they are moving across the border via land. So the timing of the certificates hitting CBT is very short. Feedback from brokers is that we need more rapid turnaround time for import certificates.

We’re taking this seriously. This is not a paper chase. If certifiers who are overseeing those exporting companies, if it is found that those products are not authentic organic, the rule allows us to hold those certifiers accountable. We do have some enforcement work ongoing against several certifiers, but because they are ongoing, I cannot talk about it. Our Enforcement website provides ongoing updates, and I encourage those who are interested to follow it.

So here’s the trend over time. A look at the green are valid import certificates in the customs system. The rest of them are a mix of different certificates that we are following up on. You can see the trend line that is slowly going up. You can see when the weekend (dips) are. Can see that there are some days when green line is pretty thick and when it is more red. Examples of things not green are when someone made typo. It’s really close, but someone flipped last two numbers when entered into customs system. Also have paper certificates, and system glitches, and working way through system but a little lag time. If our system was down even for short time, there are going to be paper certificates that show up and may be lag time.

There’s also a temporary code that customs brokers are allowed to use if they do not have the permanent 21-character code for the import certificate, but they have other evidence that the product is organic. That is a temporary code that will allow them to put the product through even though they do not have the ENOPIC. Brokers are licensed and can lose their license just like our certifiers. Customs brokers have a lot to lose if they are not following our rules. We are hearing about customs brokers that are not allowing product in because they do not have evidence that it’s organic. In many ways, customs brokers are becoming our very first line of defense that are helps in ways that we cannot know. The presence of absence – we are not necessarily going to get a call every time this happens, but it’s happening. They do this every day. For them, organic is just one more piece of the puzzle. They aren’t going to risk anything. That serves us in ways that we’re not always going to be aware of.

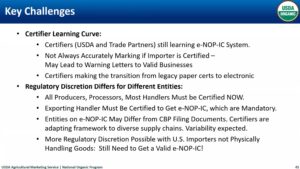

Key challenges – success so new problems. We have a certifier learning curve. Not always accurately marking in our system if the importer is certified. A few of those 700 warning levels – we got responses saying they were actually certified. Need to helps certifiers get better in OID. Certifiers making transition from legacy paper system to electronic system. Our regulatory discretion – degree to which we can support onramp into the rule – we’re trying to support legitimate trade while protecting organic integrity. Exporting handler must be certified.

I do want to note, and this is important particularly when talking to customs audience, the exporting entity, particularly on the import certifies, might be slightly different than what we might expect because of diverse variety of actors. Some variability is expected.

Even if an importer is not physically handling goods, they must be certified. Our brokers are a great line of communication for us. We do have a whole outreach community of these brokers out there who are helping us.

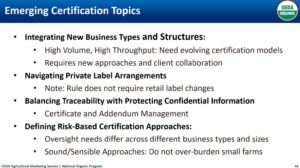

We are integrating new big players who are entering the fold. We need evolving certification models. Getting policy concerns from small farmers and large retailers. They all revolve are

How do we ensure organic integrity and also move at the speed of business? That is going to require new approaches – with small farms and big distribution warehouses. Really pleased to hear the collaboration that is happening with certifiers and their clients. These are BIG names, really big names, and we are really positioning these folks as partners in this progress. How do we do all of this so that farmers and consumers are protected?

A lot of questions about private label arrangements. Brand owners, what goes on the bag, etc. WE do want to clarify this with certifiers. Rule does not require retail label changes. We have had some certifiers tell a private label that you have to get new bags – if have a question about the rule, go ot the cost section. New retail packaging not part of the rule. If you search in private label and it references retail labels. The fact that we are at this level of problems, is a good sign. Doing something right.

Balancing traceability with protecting confidential information. We have the OID certificate, but we also have the certificate addenda what certifiers are issuing. I think there is a question of what a really high volume entity needs. Do they really need that addenda, or is the OID listing sufficient. Organic integrity at the speed of business.

Defining risk-based certification approach. Oversight is going to have to differ over different sizes of operations. There have been some very specific complaints about different certifiers and how they are handling this, so we’ve called them. Remember, certifiers are worried about getting kicked out. When I say that you’re going to get kicked out, people worry about it. We want to make sure that we’re finding a sound and sensible way to do this so that smaller farmers do not become overburdened.

We’re hearing about OSPs that might be twice as long. We have to find a better way of doing this. I have full confidence we can do this as a community.

This is where we do sales pitch on why to be certified.

All of the brokers have this information, too. It’s great to have them magnifying our voice about the value of certification.

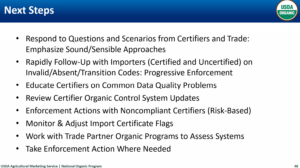

[Review of slide bullets followed.]

We are only five weeks into this, and we are already seeing some real action. We do need to monitor and adjust the import certificates flags. There are a lot of customs brokers getting pop-up boxes asking if something is going to be sold organic on something that can never be organic. That’s a glitch that we need to work on.

We are also working on trade partner module that is designed to interface between that exporter and our importer, and we will be taking enforcement action, as needed.

CALL FOR NOMINATIONS: Published this morning. We will emphasize the importance of one-to-one outreach. The Program does the same thing. We have a list of over 300 people. We do a lot of direct marketing from the Program. Want to encourage folks who applied before but didn’t make it onto the Board. Encourage folks to reapply. Timing is everything. Looking for 1 farmer, 2 retailers, 2 handling, 1 environmental protection and resource conservation. This is going to be really interesting, as the retailers have a lot more skin in the game now.

TOPP: We are going to be hearing later this morning from the Midwest TOPP group. At a national level, so far in the TOPP program, we are at 1.25 years into this, and approximately 20,000 people have engaged in the process to learn more.

When we look at the mentorship process, we have received 275 mentor applications, 375 mentee applications, and 30 mentorships have been made. Approximately 400 instances where technical assistance has been offered at this point.

TPP Goal – Once the farmer has completed a TPP, and a certifier has signed off on that, there is a desk review. Once it appears that the operation is going to be able to comply and a certifier signs off on that, that operation is eligible to be listed in the OID as a transitioning operation. Not available to the public; only available to the USDA not the public while folks are in transition.

PEER AWARD: We have a program where we give an employee of the quarter award, and when we have a peer who has won it in the room, I like to give it. This quarter, it’s Jo Miranda.

This is a peer-nominated award. The entire standards division came together to nominate Jo for this. She is such a smart employee and so helps. The primary driver for this award was the overhaul of the NOP Handbook. Cleaning out the handbook so that there wasn’t a lot of conflict between the handbook and SOE was a huge lift. Jo did not only a fabulous project management job, but a great job doing a lot of the writing of those documents. Jo, thank you very much.

Q&A from Board:

AJ: On transition in particular, just having a number to point to. 20,000 people interested in transitioning is big. Starting to get concrete and see this progress is huge. On Wednesday we will be talking about a proposal on transition, and one of the big pieces of feedback we heard this time around is about the NRCS part and people struggling to access and it’s quite uneven throughout the country. I know that it outside of the NOP’s purview, but wanted to know if you have any advice about this?

Jenny Tucker: We meet monthly with the NRCS in charge of organic programs. Have learned how differently their governance and role and structures and funding it is from how we tend to operate as a national program. My best advice is move with their system which means one person at a time. Every state is a little different. Their mission is very local conservation work. They are designed to have people on the ground providing service. Some don’t know about organic or don’t like it b/c feel not compatible with NRCS. Every office may be a littel different. Figure out how to distribute across the network.

Our TOPP folks are already doing this. We’ve had some TOPP leads that have tried to contact NRCS that haven’t been successful. There have been some challenges. We are lucky to get TOPP out and rolling fairly quickly. NRCS has had more challenges. My best advice is to work your local politics, because all politics are local for NRCS.

BC: Ignorant about – what are customs brokers roles? And whether there are other govt agencies that can helps with residue-testing part, basically fraud prevention, at the borders. Can we transfer some costs of that from certifiers, handlers, and farmers to exporters and other entities.

JENNY TUCKER: What do customs brokers do? I went to a Customs Brokers conference a couple weeks ago. They are responsible for making sure that imports into the US comply with the law. For a product coming into the US, they need to understand what the rules are for that particular product. I was sitting next to an AFIS employee that is in charge of the Lacey Act, which relates to not being allowed to bringing in endangered species into the US. There are all sorts of FDA laws that they need to follow.

BC: Are they the same as custom agents? Are they govt employees?

Jenny Tucker: Not gov’t employees. You can go to school to become a licensed broker. It’s quite a process. These can be individuals or part of an LLC. Can be multinational companies that have brokers all over the US. Impressive group.

In terms of testing, we are doing more testing now from the NOP. Aware of commodity/country combinations where we would like to do surveillance. We are collecting samples at different ports. We also have Federal Grain Inspector Service, a sister program to AMS, that already have folks at ports. They have agreed to helps us with a pilot to flip the role and do sampling of imports coming in. With SOE we’ll have a better sense of what’s coming into what port.

BC: Thank you. This is so important. Thank you for the effort you are putting into it and the comprehensive aspects.

AB: Very encouraging – early assessment of SOE. Question – transparency about acres on certificates. Operations become apparent on OID. Insight into grower group and acres and about equivalency partners – how do we get transparent data relating back to the farm. Touch on equivalency partner oversight.

Jenny Tucker: First, this is a Board recommendation that was implemented quickly. NOSB had a lot of work on acreage on certificates. It is now a required field in OSP. Grower-groups – the requirement has 2 steps. Most operations are not grower groups. Have to think about how data relates to each other. It would not make sense for certification bodies to enter in zero or one. Grower groups are linked to business type – which can be found in Integrity database. If cert picks grower groups as business type then there will be more entries to fill in for grower groups. That system will be live in about June. This is a significant lift. The number of grower group entities will be mandatory by the end of June – you will be able to see total acreage and the number of farms in that acre for certifiers. Exporters to the US – the same is true. Lots of handshakes and governance boundaries with trade partners. The operations/producers inside those govts are actually growing but are not the exporter, that’s the responsibility of the trade partner country. If there is a problem we have to work through trade partners

Good news: we’ve been doing this for a long time. Need to be aware of and monitor closely over the coming months. About 37% of import certs coming in under trade arrangements. If problems have to work under trade arrangements. Some limitations in terms of jurisdiction and transparency. We need to acknowledge how advance OID is and how transparent our system is. Might spark other govts to become more transparent. Still questions about whether really equivalent that need to be asked.

This is a process, not an event. There are country to country negotiations. We cannot require all of our trade partners enter in all of their crop and acreage information. The question is if we are equivalent. We will be sharing what we are doing on SOE, and we will be asking them what they are doing to deal with it. Having the import data will give us a better understanding of what is going on. If we have an invalid import certificate from a company with equivalence, we can ask them to investigate it.

KH: I want to emphasize that when we receive beans, does the farmer have organic labeling on his trailer. The non-retailer part of the rule is challenging. You’ve mentioned that by 5/17 you expect to have feedback from the certifier community. What are the next steps?

Jenny Tucker: Going to be, already iterative process. Had great conversation with certifier. Small farm, only produces organic, only ships to aggregator who is 100% organic. I use this container to ship from one 100% organic producer to another 100% organic producer, so does this container really need to be labeled? This is where I want to emphasize importance of the preamble. Often used to reading the regulations and there might be a line that says, “shall or “must”.

There is always going to be a call for consistency, and I want to remind us that different business are different. If I’m selling to an organization that has both conventional and organic products, their rules may be that they need to have that labeled. There might be other small farms that have a different supply chain. We need to find boundaries and business rules where people can explain critical thinking. There is going to be a bit of a conflict between sound and sensible and meeting the requirement. In general, if you’re at the beginning of the supply chain feeding into it, your burden should be quite low. We are encouraging folks to talk to each other, talk to their certifiers. There is work going on at the level of the ACA where we see groups working to solve these common issues.

Also working with NOP to ensure our auditors know what “sound and sensible is as well.”

Nate Powell-Palm: You mentioned this for a second; when we were asking the question of how we can get better as mass balances, the community said that it would be helpful to have acreage on certificates. The speed in which we could do that was incredible. I wanted to thank you for the partnership and getting that across the finish line. It was really exciting to get on OID three weeks ago and see all of this information.

JENNY TUCKER: So much of this work is possible now because of the technology being available last fall.

AJ: Excited about nomination process and want to see a diverse team coming in. What factors are used in selection?

JENNY TUCKER: For folks who have not been around the process before, encourage you folks to do outreach to encourage folks to apply. The call lays out the criteria for that. We have a strong interest in organic expertise, but also a strong interest in equity and diversity. The call for nomination and rechartering of the Board goes through a civil rights review. Think about the areas of expertise on the Board that will be leaving. We also want to reach out to a broad set of potential candidates who could really add diversity to the conversation. We are looking to increase representation in Indian, Alaskan Natives, Pacific Islanders, Native Hawaiians, and people with disabilities. Those are areas that are under-served and represented. I also encourage Board members to update their demographic information with Michelle if they meet any of these areas of diversity. USDA’s form does not necessarily include all of those different forms of diversity, but if you do have one of those areas, we want to ensure that it is reflected.

AB: Discouraging fraud: the penalties are clear domestically (fines, jail, removing certificates). What are the equivalent enforcement levels that can be acted on international folks?

JENNY TUCKER: getting better at knowing what levers are and how to push them. We have a couple of appeals cases where operations have been proposed suspended or revocation in another country. We are advancing a couple cases to Adm Law Judge. Process of serving foreign is challenging. One of reasons we ended India recognition is b/c they weren’t kicking out certifiers that needed to be kicked out and not taking actions against operation that were noncompliant. Certifiers in US system kick out about one entity per day. They can and do kick out their clients. We look at how many operation certifier has actually kicked out. We consider that an element of risk. Trade partners: also challenges b/c one to two steps removed on enforcement.

KYLA SMITH: Question during public comments: how long to see an impact from SOE? You’ve reported some early wins. Can you share when the community will see or feel notable differences domestically?

JENNY TUCKER: First, I have a more positive view of SOE. I think it’s way more than an eggbeater. I think there’s a whole lot of potential with SOE, and we should exercise optimism and faith. A lot of people gave a whole lot of comments to SOE, and I think we need to give it a chance to protect us. Give us a chance.

We know that more than a dozen customs brokers who have called us and said that they rejected product as organic because they didn’t have evidence of organic status. We are seeing a big jump in trademark violation investigations. Customs has been actively doing that for almost a year and have blocked a whole bunch of products. The ENOPIC gives them another step. We have someone regularly getting calls from customs saying that they thing something is violating trademark. That is held then based on CBP authority, and those holds come with fees as that product sits in a warehouse while it is being investigated. That is a deterrent. We are seeing a number of those go up. Those are immediate impacts. We are not getting calls from every customs broker when they mark something as invalid, but I think that the calls that we are getting are encouraging.

KYLA SMITH: with most any rule, it take a full inspection cycle to see what’s going on. Accreditation audits, as ongoing, with 3 rules, there has been a change with getting more info faster so I think program is able to act more quickly against certifiers not implementing rules effectively. More will be revealed on accreditation audits.

JD: To the questions that you’ve just been asked, I think there is another example that you gave two years ago, which is when you reach the stage with what we are doing with SOE, it is frequently ill-advised to talk about your successes. Things are happening right now that will not be spoken about for quite some time. That’s just my thoughts.

CD: Self-interest prevails. At project director meeting for OREI: slide with priorities that came out of farm bill when funding was established. And then he had list of 2 NOP priorities – one was theanine and the other did not make aa lot of sense. Do you know how those NOP priorities get set for OREI?

JENNY TUCKER: We do have a processor making sure research priorities get over to NIFA. They are an independent agency. Think they share some of the challenges. We aren’t involved in that process. We transmit Board priorities over to them.

Midwest TOPP presentations

Cori Skolaski (Executive Dir, MOSA Certified Organic) presents the Midwest TOPP program details.

CS: [Gives background about MOSA. MOSA celebrates 25 years.] Overseeing 11 states.

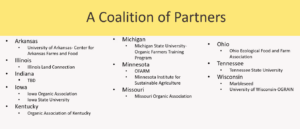

Allison Wellent: New to MOSA for the TOPP work [goes over agenda and speakers]. 5 program areas. Through these areas we continue to support farmers transitioning to organic. Midwest region is 11 states. Wort TOPP is accomplishing is possible through partnerships – 5 other regions. Partners in Midwest – identified core partner in each of 11 states. Our new relationship with national partners too – these allow us to difficult work and reach in underserved communities that need more opportunities. Midwest coalition of partners (slide) – each one has between 3 and 7 organizations leading the work in their regions.

63 matched mentorship pairs which means they are working to bring approximately 2000 plus acres into production. 98 mentors waiting to be paired. Another 12000 acres in pipeline. 44 events and will be seeing more field days and on-farm events. Supported 198 producers with technical assistance. This is beyond the 63. Area of program we hope to grow. At those 44 events, we have touched 4,847 people. In Midwest, created 61 resources for organic producers – podcasts, fact sheets, webinars. Trained 142 organic professionals. Providing support to extension agents to support farmers as transition to organic.

If we look at the number of mentees committed today and in the pipeline – 190 farms – and extend that to the next 3 years, we feel that we could be impacting growth int he northwest region by 8-9%. Our goal is 10%. Relative growth over time has been 1-2%.

How is all of this work getting done? Relationships & collaboration. Relationships with all of our partners. Listening and understanding where each is coming from.

Roz Lehman, Iowa Organic Association: Mission is to advance organic ag and food systems in Iowa. Established in 2006. Broad group of supporters that includes all organic stakeholders who are interested in championing the organic movement. We focus heavily on education – webinars, field days, works, reaching out to students on college campuses. We are finally able to add a bit of technical assistance to our work through the TOPP program. We hired an Organic Farm Advisor, who also leads our mentorship program. We are sharing information out through newsletters and email. We are trying to connect policy leaders with organic and get them out to farms. Community building is weaved into all of the priorities that we have.

Organic ag in the state of Iowa: 6th in US in terms of production. Top producer of organic soybeans and hogs. Approximately 1,000 certified operations.

Jacquelyn Evers from Illinois Land Stewardship, Nonprofit in Central Illinois. Connected with Rodale, presents for their region.

Lori Stern, Marbleseed, Executive Director: Cover the upper mid-west. Marbleseed is MOSES rebranded. Mission is the same. Huge commitment to working with historically under-served producers, including Mung farmers.

Kenya Abraham, Organic Mentorship Program, Kentucky.

Mentorship can bring equity through work force development. Mentorship is cornerstone. 12 mentorship pairs in Kentucky. Having a good coach makes a difference in how things will turn out.

[Video about a mentor pair from Iowa.]

Harriet Behar, Mentor (Soldiers Grove, WI) presents for her mentorship.

Nick Stable, Mentee (Marion, Iowa). Vertically integrated food hub in Madison, WI. Harriet challenges ways of thinking, and how to approach a problem.

Q&A from the NOSB

NL: 3 questions (1) for Nick – imagine that your mentors are in ? Category

Answer: 100% certified

NL: Lack for processing and storage for grain. Any focus on transitioning facilities?

Answer: access is constraint. The priority of program is for transitioning producers. There are a couple of awards that came through. OFARM is a partner.

NL: Last question for Kenya. Would love to hear farmer Evelyn’s story.

KYLA SMITH: Also for Kenya, you mentioned most Kentucky black farmers are not participating in the program. Can you speak to why?

Kenya Abraham: She (mentee) purchased properties in southeastern Kentucky, but she does everything she can to educate herself. Building trust within this industry is necessary. She trusts me so therefore she is willing to cross the bridge. Other Kentucky farmers, and BIPOC centered orgs- trying to gain trust. They trust me. However, their relationships with ag industry as a whole needs to be some bridges to repair and restore condition of the black farmer. You can ask me to join your program, but I’m sitting here wearing flip flops and farming in them and I don’t have my boots necessarily. Our boots have been taken from us. This USDA would not exist without the back of the salve in America. Has to be restore and repair to condition of black farmers. Obviously outside of this program, however, you have to care about it and would love to say take me to your leaders b/c it’s what’s necessary to restore condition of black farmers. It would bring about access to organic markets to black farmers and food deserts which result from apartheid.

JD: Harriet was the first person I called when I joined the NOSB.

HB: When worked at MOSES spent a lot of time on the phone help people find their own way and everyone has own perspective to bring to conversation.

AJ: Exponential growth of TOPP is impressive. Logistic question – can you send us fact sheet about applications to transition, etc. How are you reaching conventional farmers specifically?

Allison: Invite any partner to come up and answer it. Program rolled out quickly. We targeted mentorship launch 6 months after signed agreement. Some of that is going to shows and conferences that are not our typical. Went to TN, more conventionally minded conference. Our partner in OCIA is doing some advertising. So don’t have clear communications formula but acknowledge that we need to.

Unknown speaker: In Iowa we do have a strong ag network. PFI is a great resource – for farmers that are organic-curious. Important to be that space in the a state.

KYLA SMITH: Thank you for the fact sheet. NRCS program is having struggles and challenges, we’ve heard form public comment. Do you have best practices or guidance that could be applied elsewhere in country?

Allison: One of the things mentioned in fact sheet, our office was ready for the rollout.

DN: Also thank you for clarifying why TN part of mid-west. There are more mentees than mentors. How do you connect mentee and mentor and can have mentor have more than one mentee – like 3,4,5? Do you consider how farm located, size of farm, virtually, etc?

Unknown: States like Arkansas and Tenn have much less mentorship happening. So in Arkansas and Tennessee we’ve taken first year as education approach. Including educating NRCS staff. Arkansas has a serious interest in organic ag in delta area but are profoundly threatened by dicamba drift. The NOP said they wanted to see consistency in how mentorship was implemented.

We have a monthly membership subcommittee meeting.

AB: Insight into TOPP is great. Thank you to Iowa Organic Association – some of the best practices were helpful when shared with Plains region. When we look at success of TOPP and recruiting new producers – do we need to start thinking about part 2 for retention of these producers? Would that be beneficial to have in the que?

Unknown: Absolutely. Been thinking about Part 2 of TOPP. Have a lot of convos in network and we can provide mentorship to transitioning producers but also have to focus on market development and access to markets. We are only 18 months into 5 year program, but need to start thinking about what transition at end of the program looks like. What does that cliff look like and in particular as think about racial equity and inclusion, we would do disservice not to consider what end of program looks like and consider lack of trust and then to be abandoned at end of 5 years, so yes, we need to be considering transition and a Part 2 and to develop markets.

AJ: Farm Bill is being debated and funding for TOPP is on the table. Encourage people to show up in Congress in addition to here.

LUNCH BREAK

Public Comments

Note these public comments are in-person at the meeting.

Rhodes Yepsen, BPI

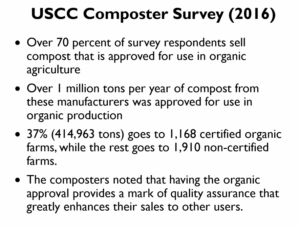

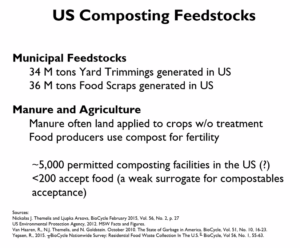

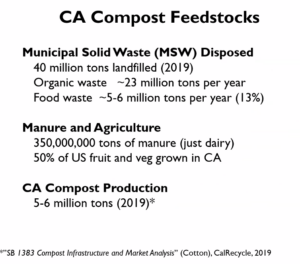

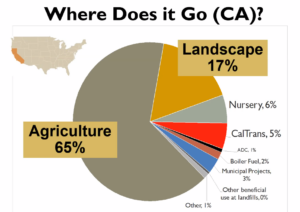

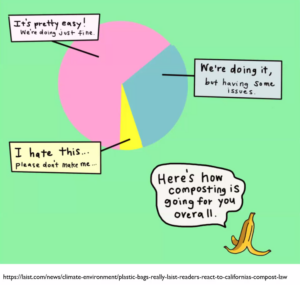

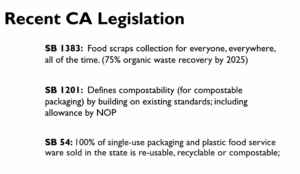

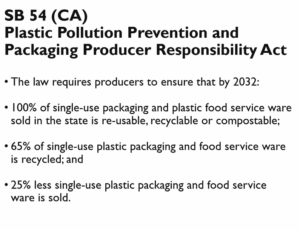

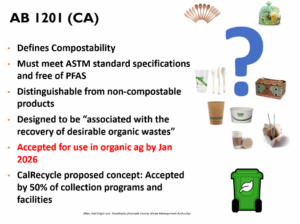

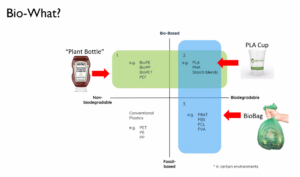

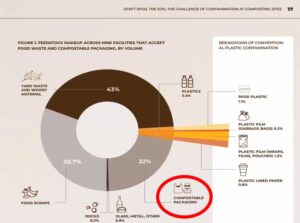

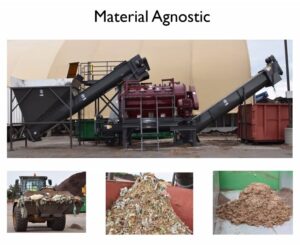

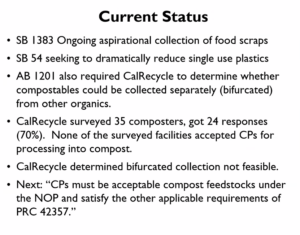

Executive Director of BPI. Petition for rulemaking on compostable products. Leading authority on compostable products. Submitted letter to USDA re: whether National List can use compostable feedstocks. Compostable products – CA demanding change. Passing laws for mandatory food scraps collection. CA also mandated it be allowable input by 2026. Based on discontent compostable products are causing finished compost to be disallowed in organic. Organic brands, coops, brands to see early adopter of compostable products. These brands will soon lose in CA. Food scrap collection bag would be disallowed. Climate emergency is created in part around packaging. Many landfills are super emitters. ASTM standards are rigorous. Encourage USDA start rulemaking process. No time to wait

AJ: Piecing together moving pieces of this puzzle and have been having trouble tracking down CA requirements. Can you send that to us? Do you know year or number

RY: The requirement is in the definition of the plastics labeling bill – not have PFAS, be allowable AB1201 and it was a few years ago.

AB: Definition clarifications. Devil in details. One, is there any distinguishing factors visually between a certified compostable product and a compostable product?

RY: Question is very key to our organization. We require items to be labeled in order to get our certification – require them to be marked so they can be distinguished. Several states have laws requiring compostable product labeling. Even when conventional products are unlabeled. CA, WA, CO, and MA included. This year we even kicked products out of our certification for non-compliance/

AB: What form would a label be put on a product?

RY: It can be many. Nate Lewis holding one. Printing or embossing are common methods. Stickers that are certified compostable. Stamps and other things. We did some work with close-loop partners on how to make things identifiable to the consumer. Coloring is important they found in consumer tests.

AB: Definitions – certification process for compostable – you’re looking at PFAS if intentionally added?

RY: Correct, intentionally added PFAS. We developed that with others – including San Franciso. It was the easiest way to track. Intentional use is done from chemical screening. Sometimes it can be from a spray you put on equipment.

AB: Is there a chance for unintentional PFAS to be no captured?

RY: if think about recycled paper, it could be getting in through that. Could be coming through in recycling stream or water, if have ground water with PFAS – how do you not use water?

MJ: As retailer spent a lot of time in stores excited about sustainable packaging. See all of us – retailers, composters, sustainable packaging – as related adjacent industries. As NOSB we are collecting as much info and expertise as we can find. So thank you for coming to our method. Struggling with ASTM standard. If I read correctly, one of them says 90-100 to 180 days. A certifier reflected to us they would have to verify composter that that occurred. If we could include compostable packaging would we then need to make sure composter has been using that amount of time?

RY: multiple tests in the standard and you have to meet all of them. Tiered from raw material to a finished package. 180 days is for a raw material. Some are 90 and some up to 180. The tests in ASTM standards are tiered so you have products by time finished been tested in retested. 180 days is in isolation in lab. If you have other active feedstocks, don’t know if biodegradations from. Challenge to test in open environment because of the variables.

If there are concerns test the finished compost. Materials do not remain if you go through sufficient composting process. Analyzed microplastics and when you find them then the compost is not finished. May not be suitable for organic agriculture.

AJ: Little info about PFAS threshold. BPI – 100 ppm. Lowest could test for was my understanding and now can test down to 10 ppm. Is it feasible to drop that standard as technology improves?

RY: The ACM standards are in a process of continual improvement all of the time, so we are happy to look at that. There are passive receivers of materials, and we are trying to protect the composter as much as possible, so if we can improve our process, we are open to that and figuring out what that new threshold could be. Denmark moved to 10 ppm.

AB: You mentioned that you reviewed some of the written comments and studies that are out there. I have a written comment, “The BPI certification says nothing about potential toxicity of a product, only its capacity to biodegrade.” What are your thoughts on that?

RY: Not true. Withing ISTM standards there are plant toxicity tests. PFAS restrictions – a lot of restrictions against carcinogens, etc. US standards for heavy metals are quite liberal. We certify to Canadian standards. All our products certified to Ontario ? Standard. Making sure our products meet requirements compost has to meet.

WT: It is hard for me to separate compostable plastic from our single-use plastic disease in this country. I think about what has created compostable plastic. Frankly, a poor labeling process 30+ years ago, so when I think about something that has to rely on certification and labeling to de3termine what is going into the system, that concerns me. I think the labeling system that was invented by the plastics manufacturers is concerning. What do you think of that?

RY: Our program is different. Chasing arrows certification is getting overhauled. Self- identified resin code. I don’t think you can compare the two. Looking at tests and certification and making sure consumers know how to dispose of item.

BC: Back to the 100 ppm threshold for PFAS; what is that specifically for? Is it a finished product, inputs – what exactly is it?

RY: finished packaged, 100 ppm fluorine. Test is readily available. We’re concerned about number of PFAS chemicals.

BC: That is for total organic fluorine. That range – can you recall what the recent EPA drinking water threshold is?

RY: EPA drinking water is in parts per trillion.

BC: Yes, it is. That is perhaps 1,000,000 times higher than the drinking water.

RY: Totally, yes. We have more than that in our blood before we’re born. We are trying to get on reasonable test criteria. We are on the side of eliminating PFAS in packaging. We are all for figuring out better testing for certifiers, but as you all know, it gets challenging. If something shows up in a part per trillion in a formula, it is banned.

NL: Can you describe how BPI does enforcement of your label? IS it a trademark logo?

RY: It is trademarked. We have a fair amount of authority for enforcing when someone misuses our mark. Some states have passed these around the use of the word “compostable.” We pursue misuse to the fullest of our ability, either to get someone to enroll in the program or pursue legal action to get them to remove the mark.

Sal Pinkham, OEFFA Certification

[Comments pending.]

NATE POWELL-PALM: What type of farmers was the transition plan with?

SP: A mix of the two. We have a working group as part of our policy program, not certification program, comprised of OEFFA members broadly, and it includes both groups.

Michael Crotser, Organic Valley

Certification director at CROPP Cooperative. I want to discuss generating organic certificates through OID. Purpose of 205.204 was to ensure consistent formatting. Goal of improving transparency and accessibility. We are seeing inconsistencies in the OID. One is that some have issue dates of the same date that it was generated. We hear that this is being corrected so that the issue date will only change when certificates are updated and products added or removed.

We are seeing either the mailing address or physical address. The physical address would be better.

We are seeing certifiers issue product addendums, but they are harder to obtain. Concerns include 1) it does not appear that OID certificates are meeting the goals of transparency and accessibility. 2) Operations do not know what they need for compliance.

We believe that these inconsistencies are creating discrepancies between certifiers.

AB: Addendums – how do you know if addendum is available for an operation?

MC: That’s a great question. Usually we have a hunch that information that we’re not seeing on an operation profile – something is missing – and then we start looking at an addendum. Branded items or private labels would be a good indication of that. If we get a certificate off the OID and it’s not showing private labels that our business manages, then we know that it probably has an addendum. Of course, it probably shouldn’t list a private label, as that blows the use of the private label. If we are struggling to know what we need in our OSP, I’m sure so are a lot of other people in the industry.

JD: You went by private label. I didn’t catch the reference?

MC: It’s kind of difficult tot talk about as a business, but generally, milk marketers, copackers in the industry will produce for store brands. That’s something our business does – bring those to market – and generally they are rolled into the OSP. Generally, everyone knows who is doing what for who, but generally that’s not on the organic certificate. Generally, the certifier will provide a private label certificate. Primarily for proprietary reasons.

Gwendolyn Wyard, Strengthening Organic Systems, LLC

Founding Partner of SOS. Mission – insure authenticity of organic products. Two topics (1) pullulan. Can be produced organically. Certified organic forms are available (pullulan). Most of production is from China. However recent exp of patent restriction has opened sales in U.S. This Oregan based co. Can make 500 metric tons and 2 billion organic capsules. However, demand is less than 30% of capacity. On commercial availability the NL allowance is for “made with” category. If company wants to use seal on capsule, they must use certified organic version. Most want to use it, but not quite there yet.

TR Templates: The proposed TR revisions around excluded methods. I believe the information could support a more accurate compliance review. The issue is how that information is used. In order to achieve the goal, improved material review policy, improved oversight and consistency will need to be coupled with that information.

DN: The analysis of pullulan is it now conclusive that it is non agricultural and non synthetic.

GW: Yes. In 2016, when classification came out, when run through decision tree, it came out as non-agricultural. That prompted 2018 petition by OTA to get it on NL so it could continue to be made with encapsulated. Otherwise was going to have “made with” capsules out the door. Yes, there is organic pullulan, but it’s really new to the market, so everyone is now working to adjust.

DN: Probably going to take years but do have option of organic now?

AB: Thank you for joining us. Question on residue testing – challenge you to come up with a solution – regarding when specific tolerances do not exist for a production commodity – what can we offer as a solution?

GW: I will refrain from answering that question here. We are working on it at SOS. Johanna Phillips would probably be better suited to answering that. I promise that we will be coming up with some options for solutions on that one.

AS: Follow-up on Dilip’s question – it sounds like we are saying we could sunset it because there is organic supply, or are you saying that we’re close but not there?

GW: think there is more research to do. Just started working with the company making it domestically. I know they aren’t fulfilling their capacity b/c there are cheaper versions out that – international.

I think I would rather see someone petition to take it off the NL than sunset it. Keep in mind that it is with the “made with” category. It’s available. It’s there. While people are building up and changing, I would rather see the shopper and the market drive us there and keep it on the list, and then have the petitioner or marketer tell us it can come off.

David Will, Methioine Task Force

VP of Sales of Chino Valley Ranchers. You have a binder that ghost writer did for us. Deep dive that was everything methioine since inception of the Board. Includes reports that have been presented and a zip drive of other reports. Everything in here. ON our slide presentation, we are represented by egg producers and broilers.

The big question is why we use methionine. It is an essential amino acid. No lysine in it, and has a nice protein value. The most leading potential substrates that we can use – black soldier fly larvae and sunflower meal. We are constantly stressed with getting enough sunflower meal.

If you take a deep dive into the black soldier fly, if you take the 35M broilers that are in production per day in the US, you would need 280 lbs/T to equal the same as the amount of methionine being used. That is a dried figure. If you take it as a liquid, it would be a little over 2.5B lbs. With every lb of black soldier fly, you get about 2 lbs of fertilizer, which is not a bad thing, but something we’d have to deal with.

NL: Would black soldier fly affect whether could label vegetarian fed?

DW: Always going to eat a certain amount of invertebrate. Have to run it through a legal challenge b/c now intentionally including it in ration.

KH: Skimmed over availability of sunflower meal in the diet; can you speak more to that? Your production is west coast focused?

DW: We’re up to the Mississippi Ocean. We do a particular product – soy free egg. Replacement we found for that is sunflower mill. Been challenged finding a source. Asked our nutritionist nonorganic something we can find. Not really available.

KH: Talk to me about sunflower meal and where it’s produced inside the US. Logistical restraints can be challenging when we talk about infrastructure. But I’m always trying to challenge what alternative proteins – we’ve heard farmers talk about not growing sunflowers because there’s not a market.

My other question: do you feel like the market would abuse methionine if there wasn’t a limitation on it?

DW: we source from everywhere. High side and low side. Always hit diminishing returns. We came back and asked it go to average of life of flock and granted that. Most can work under that system. If remove the cap, some would use more, but over life of flock, don’t see it changing things dramatically.

AB: As a producer, your comment on the sunflower meal really perked my ears. Were you running into sourcing challenges in the US?

DW: Got a lot of it from Mexico for years.

AB: this would be an incredible opportunity for infrastructure in the US. There are a lot of producers close to you who could grow this.

DW: absolutely and need a home for the oil because getting the crushed part out of it.

NPP: Could you speak to animal welfare of under-feeding methionine?

DW: Chicken needs essential amino acids. Feather pecking, nervousness, if you walk a house of brown chickens you have to shoo them from under feet. With methioine deficiency they are like white birds and are flighty. If overfeeding soybean, then extra amino in houses. It’s all across the map. Significant impact to welfare.

Bill Wolf, Wolf & Associates, Inc & Second Star Farm

[Comments pending.]

LP: From written comments on CO2, on the petition, is that okay if ask that?

BW: I can tell you that it was very carefully thought through by a group, and that answer would better be provided by John Foster, who will be speaking in a couple of minutes.

NPP: Regarding growing organic markets – when we say ask for 5% of USDA research dollars, why in this community to we have such a hard time asking for our fair share?

BW: Important to understand that USDA funding can’t happen overnight. We have to have infrastructure to manage that program well. Fact is this conversation about asking USDS and Congress to allocate funds proportional to industry, is basic business principle. We’ve been asking this for 25 years. We don’t spend the money to support the R and D. Done so much to encourage imports by our inaction.

Ben Lehman, Rodale Institute

Organic Consultant and farm organic grain in Iowa. Rodale is dedicated to growing regenerative organic movement. Share experience with 823, NRCS – provides conservation contracts. 823 contracts are extremely effective in protecting soils and environment. Communication has been a challenge. Quick turnaround many transitioning farms hadn’t developed relationship with NRCS. Awareness is highly variable. Nationally coordinated list of deadlines could help make sure funding utilized effectively. Inadequate funding for certified acres. More federal funding is needed to boost conservation.

NPP: From what told earlier, you’ve had a bit of success helping farmers access funding. How did you develop relationship with NRCS. Any takeaways?

BL: NRCS brings agents to farm, challenge some existing biases about farms that do tillage. In some of our hillier acres. Getting real experience with organic farmers.

AB: some stats on states and their acceptance rates and you said Illinois had over 140?

BL: Yes, track contract instances. 142 years contracted for farms in 823.

AB: In Nebraska I think we had two applicants in the entire state. This Illinois number is interesting. Can we find number applied versus number accepted. Did people not apply b/c didn’t know about it? Where is the root cause for not getting successful connection between farmers and the program?

BL: In case of Illinois, a huge bulk of contracts – 1/3 of national funding went to one county in Illinois. Was not heavily promoted. Most of those contracts have been successful.

Noah Wendt, Organic farmer

ANW Farms. Continuing in-person and virtual comments is important. Member of OFA, OFA crop insurance working groups, TOPP mentor. In 2015 we began aggressive transition. Crops we grown are corn soybeans, hemp. We realized need for local grain elevator. Purchased elevator in 2022. Barrier to entry (1) lack of capital for non-hedgeable commodity

1 – Lack of capital for a non-hedgeable commodity. This is where we struggled, because we couldn’t secure and operating note. It would be great if USDA could offer help in this area.

2 – Lack of infrastructure of rail cars. It would be great if USDA could allow some grants to allow small businesses ability to ship their products.

3 – Lack of buyers due to cheap imports. Often times this forced us even to compete to buy the grain, because there wasn’t enough margin. The buyers would always tell us that they wanted to buy as much domestic grain as possible, but then didn’t want to pay our prices.

After Jenny’s update this morning, I’m more hopeful. Due to the events listed above, we were forced to close our business in March 2024. I do still have the desire to make this work, but there need to be some fundamental changes. I hope that SOE brings them about.

NPP: Thanks for the clear example. If hadn’t seen prices crash, what do you think your elevator would have done for your community?

NW: I definitely do, and that was the goal of the elevator – to promote organic production and form a community of producers that were within 50-70 miles to make it efficient for them to haul to us and have all of the different options that they might need. I do think that if prices hadn’t crashed and we were still running, we might have had the chance to build that.

KH: Having you present, in-person, goes to show we appreciate effort you made to come and also understand virtual and how important farmers’ voice. Can you speak to any communication you’ve had with railroad entities to provide some benefit of cost saving to move product within the U.S.

NW: In the 1.5 years that we were open, we did have pretty extensive communication with railroads. It was quite a fight to get the cars when you wanted/needed them. One of the biggest things that we struggled with was the lack of dedicated organic cars, so we’d have to clean them out. Other than those things, the railroads were generally decent to work with, other than the logistical frustrations.

AB: You mentioned about end user and cleanliness of rail cars. When looking at imports also looking at clean out process – shipholds, containers – can you talk about what they wanted you to prove in terms of cleanliness?

NW: Generally, they wanted swept and blown out. We didn’t have to go to the extent of powerwashing, but even sweeping and blowing out can be a big feat if you did not have the correct equipment. And an affidavit.

Kate Mendenahall, Organic Farmers Association , Organic Farmers Association

[Comments pending.]

AJ: Our transition proposal we will be voting for on Wednesday – sounds like you are asking us to do something beyond that?

KM: Yes, when the EQIP program was rolled out it took awhile for it to be useful for producers. The rollout this year was scattered so I think it would be helpful.

AB: Comment the other day that need for organics to reach across the aisle to Farm Bureau and others. Do you see that to be a beneficial pathway to get more attention to needs we have.

KM: Not sure about Farm Bureau, but think we need to be putting selves forward and forming relationships with industry groups. We need to find out where make the most wins. So yeah, bring in other groups to learn more about organic – always a positive thing.

NPP: OFA has been active in recruiting new NOSB members. How can we chase 2 goals. Find representative folks from diverse background and find competent folks?

KM: Should always be a top priority to support diversity. It’s hard to be a farmer and serve on the NOSB. Any self-employed business person feels that. Whatever we can do as a community, we should be innovative – opportunities to support BIPOC farmers with fellowship who may want to serve or hire someone to handle farm. Need to think about English second language folks on board. Encourage community to find diverse set of qualified leaders.

NPP: do we know who those rockstars are we want to recruit? Or is there searching we need to do yet?

KM: Many rockstars do not feel they have the time to serve. When NOSB recommendations move to rulemaking it shows how they can make more of an impact.

Kelly Damewood, CCOF

CEO of CCOF, serve on management committee. No specific recommendation: share CCOF internal conversations after a CCOF organic dairy in the media. Greatest strength is scrutiny. The greatest challenge is federal enforcement; it’s slow and enforcement is slow and producers have rights. We do issue corrective actions. Standards prohibit certifiers from sharing specific info about our clients – so we see a lack of understanding and trust. We welcome partnership and want to explain the enforcement process and help it be understood. Beyond certification, the article said the “system failed the cow”. I disagree, the system failed the farmer. And when we fail the farmer we fail the cow and the land. Enormous pressure especially on dairy.

When we read articles like this, we evaluate what we would do differently or better, but we also look at the bigger issues and ask how we support the farmer, because when we support the farmer, we support the cow, and the dairy, and the land.

NL: I appreciate the sentiment and you being here in person. In my work at WA Farmland Trust, we focus on a land-focus in our work, but we are trying to become more farmer focus, with land being one tool in our toolbox. Can you talk about what CCOF is doing in this work?

KD: Little bit of everything. Sometimes advocacy, financial aid, conservation. Can be a lot of misunderstanding from env groups. Technical and bilingual assistance. Really looking at all different angles depending on farmers need, region, and location. If we don’t have farmers in business then no-certification. Really is a little bit of everything.

WT: I appreciate you showing up. We needed to hear from you today. I think often in the organic movement we take the criticism and put our tails between our legs. You mention retailers specifically. I’m curious if you think the retail toolkit that was described earlier today has the potential to improve things for farmers, and work for farmers, and work for cows… Curious if you had any reaction to that?

KD: As much consumer education as possible. What’s also broken is how price premium breaks down for the farm. Certification costs are increasing and how are we supporting farmer on other end. In CA increasing regulation. Have to look across entire supply chain when looking at market dynamics. This is very important to us. The process is working. Are there different systems to put in place for larger diaries – willing to look and overall proud of the work we’re doing.

AJ: Every time I see one of these headlines that says, “The real truth about organic,” my heart sinks. Often, it’s picking at the edges and not showing the big picture. I think one of the reasons that these articles get picked up is because consumers do not understand agriculture. I do not think people really understand a dairy operation. Do you have thoughts about how we can help consumers understand that it’s not like dreamland or the worst of the worst, but that there is a practicality that we should all understand about food.

KD: If look at commentary of article, it’s really about value of livestock products in general. Want to commend, organic grant program that uplifts organic certification process that speaks in no-wonky way about what organic means. We need to be on digital platforms and thinking like digital marketing professionals. Can’t think of more important Farm Bill priority than market development grant.

Philip LaRocca, CCOF

Organic farmer certified in 1975 – grape and wine. Chairman and BOD for CCOF. Yeast used for fermentation and malic acid – also fermentation. Peracetic acid is also very essential for organic wine and beer makers. Importance of marketing organic to everyone. Every representative on my Board comes back and stays they need marketing and needs consumer education. Farmers saying they can barely hang on and would make more conventionally. Everyone is here because this industry is built on the back of the small organic farmer. If we produce $79bil product – people are spending this money, why ar they doing it? All of the above,. We need to get that out to the consumer. We are better than conventional. Organic farmers take so many risks. We need to tell that to consumers – the word premium irks me. It’s not a premium. What we get is the money we are making is the cost of doing business. We need to say we are better and we shouldn’t be afraid to say that.

AB: I agree with your comment on “price premium.” It’s the cost of doing business. Good point. Earlier today we heard from Dr. Tucker about some of the early wins of SOE and how that related to wine. With our equivalency partners noticing that some of the wines that were being imported actually had materials in them that weren’t allowed.

PL: had this dialogue last year and what was hurting organic wine market are imports from Italy and France. In addition to not playing fair, they were cheating, but other problem have to deal with is that grape growers there are subsidized. They are given guaranteed price in Italy. Imports from Chile and Argentina they are paying 10 per day. In CA 20 per hour. Cheap imports subsidized and perhaps cheating that hurting the cause.

NPP: Do you think it is a good path forward to think about how every raw ingredient we sent to the EU or Canada, they test, and we test very little that is coming from them to us; do you think that playing catchup would be the way to go?

PL: I agree with that. As long as it doesn’t increase price to American growers. It’s costing us $80,000 to get into our new program. We’ve always been grumbling about certification costs, but stronger these days, because we’re all experiencing hard market.

NPP: In this room, we are good at coming together. You gave us so many good takeaways for the message we should be getting out to consumers. How do we start to organize and pool funds to get those messages out?

PL: I think organic farmer should be subsidized by federal government – we’re keeping people and planet healthy. I think we should say offering product healthier for environment, for human beings, etc. etc.

JD: I would like to thank you very much for saying yourself to this Board that there are some things that we just cannot do. I have colleagues here with whom I’ve spoken about how we affect the market and how we can change things, but at the end of the day, there are just some things we are not supposed to be doing and we wouldn’t be effective.

Scott Rice, Organic Trade Association

Senior Director, Regulatory Affairs. Member-based organic representing organic business across North Am. Grow and protect organic.

Appreciate the perspective of both sides of the table. As a Board member, yo uhave the desire to push forward and get things done during a time that passes too quickly. Just as your time on the Board passes too quickly, so does that 3-minute comment period. I’d like to echo the comments of Mike Dill with his ideas on how to address this through opportunities throughout the year.

We will be gathering colleagues to talk about the inerts issue, and look forward to sharing those on the open docket.