Join The Cornucopia Institute as we keep you informed via web updates and live tweets from the National Organic Standards Board (NOSB) meeting online.

We will be sharing the play by play of the meeting on April 25, 26, and 27 below and with our Twitter followers at #NOSB.

For background on issues up for discussion at the meeting, see:

- The NOSB’s Proposals & Discussion Document for Spring 2023

- Cornucopia’s formal written comments

- Cornucopia’s notes on the oral comments for the Spring 2023 NOSB meeting

- Additional information on this meeting and past meetings dating back to 2012

Tuesday, April 25, 2022: Spring NOSB Meeting, Day 1

Call to Order, Agenda Overview, NOP Introductions

Jennifer Tucker, National Organic Program (NOP) Deputy Administrator makes some introductory remarks and introduces the NOP staff.

NOSB Members:

- Handler/Processor: Gerard D’Amore and Kimberly Huseman

- Retailer: Mindee Jeffrey

- Organic Producer: Nathan Powell-Palm, Amy Bruch, Logan Petrey, Javier Zamora

- Public Interest / Consumer Interest: Brian Caldwell, Carolyn Dimitri, Allison Johnson

- Certifier: Kyla Smith

- Scientist: Dr. Dilip Nandwani

- Environmental Protection & Resource Conservation: Wood Turner, Dr. Franklin Quarcoo, Nathaniel (Nate) Lewis

For more information about the NOSB members, check out the NOSB’s biographies.

NOSB Board Chair, Nate Powell-Palm makes opening remarks.

Dr. Jennifer Tucker, NOP Deputy Administrator calls the meeting to order.

Welcoming Remarks and Comments

Dr. Jenny Tucker introduces the topic and speakers for the welcome commentary.

Organic Transition Initiative (OTI) – 300 million dollar initiative to support existing and transitioning farmers who want to explore organic option. To be here today 6 months later to be able to hear from members already doing field days is remarkable. TOPP is 100 million program. We have set up 6 regional partnerships and includes states that already have a number of organic farmers and those that are underrepresented. Going to be hearing from partners in southeast region. Already doing field days and are really having difficult conversations about what is going to get funding and how going to served community best.

The five areas for each region in the OTI:

1. Mentor-mentee program – connecting local farmers.

2. Local technical assistance – local field days, business planning, market development, understanding how to negotiate contracts.

3. Workforce development – developing expertise for organic farms and the generation that will oversee (including inspectors)

4. Community building – where local organic folks can find each other.

5. Data and reporting – How do we get that number of organic farmers and acres up? Organic is good for planet, good for people.

Running TOPP out of the National Organic Program (NOP).

Dr. Tucker introduces Billy Mitchell, the project manager for TOPP in Southeast (with Florida Organic Growers (FOG)).

Billy Mitchell: On behalf of FOG and TOPP welcome you to Georgia. Honor to share the stage. Recognizes panel and those working on TOPP. Thanks Jenny. IN southeast FOG is working with amazing partners in 7 states and 2 territories. Includes community based organizations and universities. Work is lead by those who reflect communities. Farmer to farmer mentorship program provides mentorship, community building – hosting on farm gatherings and connecting producers with resources. Tehcnial assistance – share on farm solutions that inform field-days and trust builds better resources, identify barriers, an translate rules and regulations. Producer lead tech resources benefit community. Workforce training – educate future growers, word is out that people awant to work at farm, aggregators involved in future certification. This is unrelated, Hearts of Harvest strawberries are out of this world and flowers take breadth away. Thanks USDA for opportunity and funding and to build organic communities. We truly believe partners and producers will create meaningful change.

Don Cooper: (No slides.) Georgia Organic Peanut Ass’n (GOPA). Former program director. Not for profit cooperative. Wife and I fell in love working with organic peanuts. Farmers couldn’t be here today. Farmers preparing fields. Cooperative formed in 2019. Georgia largest peanut producing state. We are startup organization. Have been working over decade and want to move certified organic forward. Georgia, Florida, Alabama – GOPA aggregates crop and markets final product. Certified organic supply chain would not exist without GOPA. Only one certified sheller in the state. Processing is very limited. Organic peanut production in subtropical environment is very challenging. Some farmers have walked away. Farmers yield quarter of what conventional grows. Steep learning curve with seeding and weed control. Need to continue research to educate them about organic certification. Need to invest in farmer led research and in soils and climate. Thanks Florida Organic Growers for including in project.

Jerry: What were the pounds per acres again?

Don Cooper 8k pounds an acre is common for conventional, but only 2k pounds per acre is typical for organic peanuts. Weeds are our biggest challenge.

Nate Powell-Palm introduces Dr. Shandrea Stallworth.

Dr. Shandrea Stallworth: I am from Rodale. Come from a wheat science background; I am familiar with the challenges of the SE. Worked in University with genes and Rodale sees a value in that. Will be offering technical consulting services to our TOPP members. Our consultants have been trained by Nate Powell-Palm in organic inspection. My team is young, but over 4 years grown to 3 consultants. We try and place our consultants where there is a specific need. We are working on several projects, including determining which veggie varieties work best regionally, getting rid of plastic mulch, etc. Rodale is also part of TOPP discussions going on across the USA. We want to help our farmers understand the NOP and the challenges of organic production. Happy to be a part of it.

Nate Powell-Palm introduces Roland McReynolds.

Roland McReynolds: Thanks everyone. CFSA is a member driven, farmer based serving North and South Carolina. Been around 45 years next year. WE provide a range of services to support farmers and businesses entering local and organic. Began organization as certifier prior to NOP and since have focused more on education. Host conferences for organic and transitioning. Support research and work with farms to conduct on-farm research, run incubator, and conduct participatory research programs, working on climate smart research, and provide technical assistance to help farmers adopt organic high tunnel, conversation, OSPs. Our role in transition partnership – Carolinas have constellation of NGO and land grant institutions that have worked to support organic. North Carolina is 8th ranked state in production by sale and leading state in SE region for organic sales. SE TOPP program is providing orgs greater bandwidth to expand opportunities for organic ag. Supply chain infrastructure, on farm packing and storage to local organic grain marketing facilities and as well as independent poultry and livestock processing. Increasing farm and mid-scale farms access to funding for transition, decision support tools, and increasing access to risk management. Program presents great opportunity over next 5 years.

Amy: Increasing access to risk-management tools – can you define that more?

Roalnd: Comes in different shapes. Small farmers can spend money on things like row crop covers and it will be more useful for them than insurance or loans. We support farmers to reduce their costs of production and make it easier to adapt to the risks in agriculture.

Amy: Thank you for talking about the FSA component. “Storage loans” – do these need to reflect transition or organic pricing currently? They default on conventional price.

Roland: We’ve looked at that with small scale fruit and veggie producers. Investment into better shelf life is often what those folks are looking for. Microloans are also useful (less than 100k).

Kyla: Wondered – TSP and helping producers with OSP. What are benefits of common OSPs – access to programs across agency and burden reduction.

Roland: didn’t provide testimony in written comments. At annual conference we have put on pre-conference workshops about how to fill out application and OSP and only moderately useful b/c every certifier has a different form. Certifiers could eliminate that as obstacle but need to learn how this change would affect other aspects of the operation.

Jerry: I know North Carolina as a volume grower for sweet potatoes and blueberries. What are the top crops you deal with?

Roland: About 2/3rds are diversified vegetable. A large contingent of mid-scale producers where tobacco, sweet potato, and wheat are their organic rotation.

Carolyn: You covered so many topics – on farm research activities grabbed my attention. How do you develop the partnerships? Think it is important to feed into EOIR funding.

Roland: certainly land grant partners have had excellent programs. For our work, we don’t compete for those sorts of grant. Emphasis is on applied research. Tomato grafting has been area of research. 5 page report we produced was most read report by my BOD b/c it was practical information they love. Focus on supporting applied research.

Carolyn: One interesting thing I’ve observed: on farm trials at Universities versus what happens on organic farms – there is a huge gap in yields and other aspects. On-farm research should be the way to go.

Roland: Incentivizing our university partners to do more of that is important. Because it’s a pain. We have to make those incentives stronger for academics to pursue that.

Nate Powell-Palm introduces Michael Wall, director of farmer advocacy at Georgia Organics.

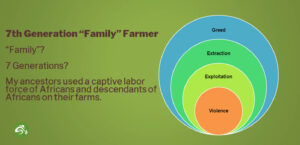

Michael Wall: Presenting about Georgia Organics and ag history in Georgia. Probably feel a little uncomfortable. A lot like CFSA. Roughly 1200 farmers in network. Had annual conference earlier this year and 500 farmers showed up. Often copy and paste Roland’s great ideas. Similar organizations. Accelerator program – farmers get about $10,000 for on-farm investments. Have a champion program – look for stickers on restaurants. Bridge program provides 2 years of free health insurance. Farmer Fund – were able to distribute $200,000 to farmers hit by storm.

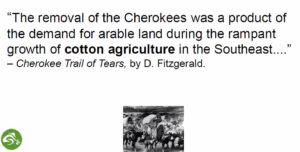

I’m a 7th generation family farmer. I’ve helped 30 farmers transition to organic. 7 generations means ancestors used captive labor force of Africans and descendants of Africans on their farms. History of GA: 1611- 1751 slavery banned. 1751 stopped and slavery takes root. 1973 cotton gin invented in Georgia. Accelerated monoculture and with that came institution of slavery.

Cotton was a bountiful crop and lead to increasing number of forced slave labor on land. We’re on land that was held by Cherokee people. Treaty of New Echota – relocation to Oklahoma. Trail of tears was because of cotton agriculture. Ag in Georgia started as exploitive and would argue still today.

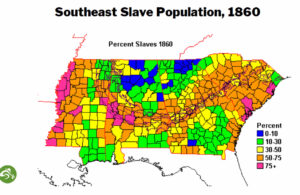

Shows slide of density of slave population in southeast. Swooping line is pattern that will see – about geology and plate tectonics. Brighter the color the higher the concentration of slaves.

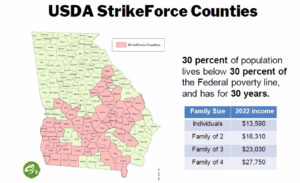

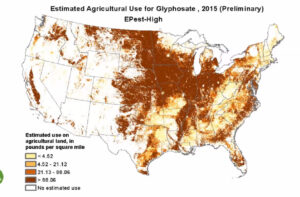

How many know what strike force county is? USDA designation – 30 percent lives below 30% of federal poverty line and has for 30 years. Entrenched poverty. The line is not moving. My family farmland is in strike force counties. Paraphrase Amber Bell: people think poverty is miss delta or app mts, but poverty in Georgia is not budging. What does this have to do with organic agriculture? Shows slide with glyphosate use – predominately row crop where strikeforce counties are.

I work on spreading organic industry b/c organic hotspots philosophy that it makes a difference in economic in region. A $2000 income boost changes lives in strikeforce counties. Enough organic industry stacked with recommendations USDA equity and reparations would mean justice for strikeforce counties. Number of organic farms grew 121.4 percent growth in Georgia. For some reason 51% of black farmers in our network are landowners – crazy statistic and need to replicate it. Other things black farmers are behind in terms of post-harvest handling. Georgia Organics official equity statement (slide).

Have some efforts pointed toward equity. (slide) AT least 50 percent of Accelerator farmers must be BIPOC. 25 percent cost-share available every year for BIPOC organic.

Dilip: How much percent of cost share do you offer to organic growers? 50% is the current level from FSA/USDA because cost share was reduced.

Michel: In Georgia it is 75% but you have to apply twice, once for $500 and one for $250. FSA/USDA program. Georgia Organics gives 25% reimbursement for white farmers during transition for BIPOC farmers, every year.

Implementation of racial recommendations – value there and hopeful so think and hope USDA all employees will lean into recommendations and see how to get implemented. Training for staff, especially for FSA staff, believe racial equity training for all FSA staff especially those on local level. You can have a great leader committed to anti-racism in DC, but has to filter down to local levels.

Nate Lewis: Can you talk about appetite for organic research at land grant universities.

Michael: Amongst organic researchers I know – they are passionate. But conventional ag dominates in Georgia. And therefore dominates land-grant. So Georgia Organic is trying to be an extension specifically for organic. Organic is not usually embraced or highlighted at all.

Nate Powell-Palm: when you look at farm numbers, 162 farms, as we look to TOPP and getting more acres into certification. Do you feel like current organic farms are thriving? Are we missing key infrastructure and how do we build resilient marketplace.

Michael: Not thriving financially. thriving in other ways. I would call reality of farming right now a crisis. Stability is not there. Forget prosperity, stability would be nice. Truth is that it depends. Closer you are to Atlanta, the better. Athens is also good. Restaurant sales. But further get from Atlanta the tougher it is. If look at strikeforce counties not even thinking about buying organic. What infrastructure we need –farmers need to feel financially stable to transition. If consumer isn’t financially stable also not going to try. Economic dev would help – spent a lot of time in strikeforce counties, and folks do it for couple of reasons – to make money, to take a stand, and others doing it because see neighbor doing it or see a farmer they respect doing it. Need more markets like the Atlanta market – consumers with disposable income and willing to buy organic produce. Growing is just as good in other parts of state and can grow in every county in state.

Kim: Can you speak to farm-to-school program?

Michael: Right now the program has shifted over to farm to early care centers. Working with local growers, helping with production, post harvest handling, etc. And then aggregating that produce and providing it for discounted price to daycare centers. We now have lots of campaigns across Georgia. October is farm-to-school week and we have been trying to get kids excited about food various ways.

Nate Powell-Plam: Theme of a lot of incubation – spawning more and more organic farms where they all support each other. Thoughts on how we can track that networking effect that Georgia Organics has had on the local community?

Michael: Impact tracking is challenging. The social resilience of farmer-to-farmer network is so valuable but it’s difficult to track. We need a sociologist.

Dr. Tucker: How are you going to track the impact of TOPP? What are the numbers/metrics of what we need to do? We encourage tracking stories of real life impacts as well. More qualitative data. Data gathering is a real challenge with TOPP.

Michael: it would show up in some of the numbers. Besides acreage increase, there is a safety buffer b/c of the relationships. Happens all over the state. Introducing Paul Sorah: met at food safety training. Paul is here to tell us about his farm.

Introduces Paul Sorah, farmer.

Paul Sorah: Pleasure to be here. Thanks everyone. Wife and I and business partner started Hearts of Harvest. In Arnoldsville, GA. Entering 6th season.

We have 1.5 acre and purchased 108 acres and expanding. Diversified fruit, veg, flower operation. In fruit world, grown a lot of strawberries. Also focusing on organic fruits. At 2 weekly farmers markets, 2 wholesale customers, and 7 restaurant when started farm, all I’d ever done was kill house plants. I was a touring musician in buses and planes. Wife and I living in Atlanta and decided to slow down. Were going to build a studio and farmer gave me book about organic and biodynamic and opened whole new world to me. Books don’t tell you that Georgia is a lot different – weeds, pest, disease, rain – dumped life savings into starting a farm. Business partner Mark came down and been getting after it ever since. Diversity of our production was critical for any shot of financial success. Ebbs and flows of veg production is volatile. Having flowers has been one of most crucial parts of business. Overhead of labor is better than veg production size of things. First year doing about a half acre went to two. Started farming that and now will be 25-30 acres this year. Ordered green house. Built high tunnel in shin deep mud. Grow sweet potatoes. Flowers have expanded for us and now have over 3 acres. Labor is a big challenge b/c way look at managing farm is that these people are in my circle. I take care of people. I pay well. Cost of labor is a reality and yes trying to invest in machines but costly and in this hybrid space, the processes and systems you need – we’ve tried to shrink full-time staff with sustainable wage. Raised money for cancer treatment for employee. Theme of networking and community is a powerful thing in our area. When I started, I knew nothing. Learned a lot from other farms and helping each other. Extension to Georgia Organics – we lost over $100,000 in 2 nights in storm in December and they stepped up to provide assistance. WE were part of Accelerator program and we growing mushroom and can produce year rough in-door. Trying to build in layers of revenue that can build in resilience. Have bunch of blueberries. Planted about 10,000 strawberries this year. Reality of taking brand new piece of land and bringing it into farm – worked with FSA on loan – those things can be challenging too. Grateful.

Logan: Could you state what kind of impact it would have on you if you didn’t have plastic mulch as a material?

Paul Sorah: There are certain crops that I didn’t know how you’d do it – anything that is going north and south. You either would have to set up spacing 8’ apart to where you could get a tractor between the rows, and giving up a whole row of production, or paying people to do manual weeding. We invested into an old belly-mount tractor and we are experimenting on some other types.

Franklin: Apart from existing farmers adding you to ???, are there things that you think would help marginalized farmers?

Paul: Organizing any kind of community-based cooperative. We just did something with GA Organic where we started a community based cooperative where we were able to cut cost by buying bulk.

Nate: Could you talk more about building cooperatives, buying and selling power? Have you explored the formal cooperative?

Paul: There are a few of us in the area that are going into this place of 25-40 acres of production. The reality of that is that… To be able to provide organic food from real organic farmers, I think we have to look at each other’s farms as part of the greater farm. Have an aggregate organize crop planning where we could be a larger distribution model. Where if someone needs 500 lettuce heads… I think that developing a cooperative in that way – there is something like that in NC – there is a cooperative who are distributing to grocery stores all over the east cost, but we do not have that thing here in GA.

Logan: Right now you are very diverse. If you were to join a cooperative – you might have to simplify to scale up for the equipment. But you benefit from being a diversified farm right now. So when you start segregating it could cause issues.

Paul: Absolutely. Feel like challenge with hybrid model – going to do farmers market because Buckhead market is fantastic and need it for diversity of sales. Looking at farm thinking 7 acres high rotation restaurant production and then 10 acre block on rotation and cover cropping. Still remain diversified and collaborate – I’ll take radishes week 1, you take radishes week 2 – and infrastructure that comes into play when trying to produce on large scale –packing, washing, and pick-up, and storing and food safety and quality – these are big barriers.

Franklin: Particularly interested about cooperatives. Not able to stay together for long. Fall apart and most of time technical assistance and sort of ignore group dynamics and how to stay together as a group. Contracts that insure things are done. Think w/ cooperatives to help small farmers, there is more needed in terms of technical support and training to make sure they stay together.

Paul: Yes, I do. It may just be a shift in what we think of as a cooperative or how we are defining it or identifying it. For instance, with Fresh Harvest, which is a company we work with, they do home delivery of over 3000 boxes across Atlanta every week. There are 10 of us farms who work with them – supply them stuff, and they handle the boxing, packaging, and delivery. We are all working together, and they are the hub. I think that hub piece is what is important. There are growers in my community that aren’t going anywhere. If the hub piece is there and the ability to distribute more and more product, I do not think the farms in my community would want to get out of that situation. We are all looking to sell more product. The group dynamics is always going to be a thing. Maybe there needs to be more assistance and technical research done on how to make that effective. But I think that for farms like us to thrive financially, there is going to have to be this access to distribution that is not all tied to large farms on the West Coast.

Nate Powell-Palm: What is the value that being certified organic brings to your farm? Why organic?

Paul: We are actually putting our new property in certified. I have been operating under the NOP/OMRI organics since the beginning, but it has been overwhelming to us on the paperwork piece of it. When you already feel that you are burning at both ends and working 60-hour weeks, it’s hard to come in and put in data. We are certified ??. If you operate organically, but you still do not have the label, you’re getting conventional price points.

Dr Jenny Tucker: Thank you to welcoming panel. The TOPP investments are designed to harness the power of partnerships that are already there and working. Illustrates why the TOPP program was able to get going so quickly.

Secretary’s Report

Amy Bruch, Secretary, approves the minutes as written.

NOSB Report

Presentation by Nate Powell-Palm, NOSB Chair.

The day before I left for Sacramento, it snowed in MT, and it has not stopped snowing even until now. It has been a really cold, hard winter. It has been hard to keep animals alive. It has been discouraging not to get into the fields.

We, as a Board, have gone through a lot over this past 6 months. It’s been a dynamic and challenging time. I look to all of my fellow Board members on how we embody resilience. I think about how when we were on the farms yesterday, they were talking about if you’re not a sustainable business, there’s no way you can be a sustainable farm. It’s the same with the Board.

We have come through a lot on the Board. I want to give a really big shout out to our former member, Liz Grazniak. She came from a very productive farm, first generation. After the last meeting, she came to leadership and said that she thinks the Board is great, but that she just didn’t have time for it. She served us so well, but handed off the baton when the time was right.

That’s something we don’t talk about when we are recruiting. It’s okay if it’s too much. We are grateful for all your service. The fact that we are still here shows that this community is going to last. The work that we are doing is in the right direction.

I want to thank you all, to the community, and especially to my fellow Board members. We spend a lot of our lives in organic protecting what we saw as our seal, in a way, from the USDA. We weren’t sure of the USDA as a partner, and I think we have an incredible partner in Dr. Tucker. I would encourage everyone – we won’t always have her, and she cannot get everything done that we want to get done, and the program cannot be everything to everyone – but I encourage us to figure out how we can get as much done in the time that we have.

Encourage everyone to bring your big ideas. Who has the right skill set ad authority to do certain work? We can get an incredible amount done together, and I think that’s evidenced by what has been heard today.

USDA/AMS/NOP Update & NOP-NOSB Q&A

Dr. Jennifer Tucker, AMS/NOP

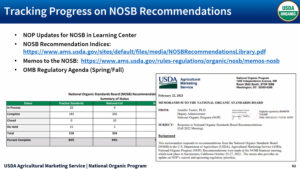

Dr. Tucker: I am going to give a short presentation. Part 2, because Part 1 is in the learning center. This is something we kept from pandemic and works really well. We used to come here and talk for 45 minutes. Instead, only going to talk for a few minutes and then open up for questions.

The Organic Learning Center gives presentation on everything been working on.

The National Organic Program (NOP) provides a program update before each NOSB meeting. Even though we are meeting in person in Spring 2023 we are continuing to provide the NOP update in this pre-recorded way for maximum viewing flexibility, so you can watch it at any time.

It is now available in the Organic Integrity Learning Center and can be accessed within Course “NOP-998 – NOP Presentations.”

- Direct Link: National Organic Program Spring 2023 Update for NOSB

- Need a Learning Center account? Access sign-up page

- Have a Learning Center account? Access site

For questions about the Learning Center, contact [email protected].

Usually get asked about the status of rules so wanted to remind about rulemaking process. Right now we have rules and tomorrow morning we will have a box for public comment, so lots of rules in pipeline. (Slide shows overview.)

Strengthening Organic Enforcement (SOE): Implementation and talking with certifiers about what it means.

Origin of Livestock (OOL): Enforcement phase – now enforcing and asked certifiers to give us updated systems and how implemented and surveillance team has it on schedule to access compliance.

Organic Livestock & Poultry Standards (OLPS): Final rule that is now in legal review; finished drafting process; now in legal review.

Nitrogen Rule: Working on a proposed rule – very recent NOSB recommendations related to nitrogen fertilizers.

Market Development: Addresses pet food and mushrooms – working on this.

SOE: Want to emphasize this – a number of important provisions. This is game changing. That is a term we have been using. It changes the games in that certifiers are going to need to do comprehensive updates to their entire systems based on risk. It addresses risk mainly in the middle of the supply chain – brokers, handlers – people working in complex supply chains are the ones that are most affected by this rule.

Big ask – please help us emphasize the importance of certification. Anyone who is actively engage in handling and arranging organic trade need to get certified. There are not VERY FEW exemptions. Important for them to get started on certification.

There are 4 key ways that people can stay updated on what we [NOP] are working on. We keep a scorecard on what we are doing and how we are doing, and that’s part of how we are assessed. We also report back to the NOSB in memos to the Board that we issue after each meeting. We have recently added a section on regulatory priorities – that will report on where our priorities are until the next meeting. I think if you look at the rulemaking slides that I just covered, that is what we said our priorities would be, and that’s what we are working on.

Inerts: Inerts are a complicated topic. Wanted to layout next steps for the NOSB. Was issued as advance notice of public rulemaking after many years of work. Inerts – overview: Ingredients other than active pesticide ingredients in pesticide products.

Supports those lists – long time that we’ve had these inactive lists. There are a lot of materials on List 3 & 4 that farmers rely on every day. We issued an advanced notice of proposed rulemaking to outline the work that had been done and ask stakeholders which alternatives could be used to replace List 3 & 4.

Almost 400 comments in response to that AMPR – good news – about 70% of the problem, we have solutions for and there is broad agreement on it. That leaves the other 30%.

So, the next step is that we are going to be providing a Work Agenda request to the Board – likely this summer – where we will summarize what we believe the 4 key options might be based on public comment with some pros and cons – analysis of AMPR. Based on those 4 options, we are going to ask the Board to make recommendations to the program on different options on addressing this 30%. We are going to put a time limit on it – only a certain # of meetings – because we want to get this done before Lists 3 & 4 come up for sunset again. We need to get to a final rule within a certain time period, or we will be back where we started.

Therefore, I am asking the Board, please, please, please, when you are working on recommendations, give us all possible options that you think are feasible. We cannot add a synthetic to the NL without you. We need a recommendation from you to put a synthetic on the NL. If you give us a recommendation that is untenable for cost or feasibility or benefits, then we are right back where we started from. We need something that we can get through rulemaking that takes into the costs to farmers. That is different from the criteria that you folks work with at the Board level, but we need something, because we cannot do anything without you.

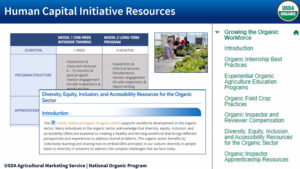

Technical support: The NOSB needs help. We’ve heard for years that the board needs help. Board did really good work. Appreciate all dialogue and public comment. We are ready to give you some help. Appreciate you gave us options. We are working in complex federal system that has strict hiring and budget rules. We have written a position for staff members that would be able to help – doing research for you, reviewing public comments, so providing with staff level support. We are proposing to staff within NOP. A lot of them are here today. Those folks will need to help you in a way that can support rulemaking process. We are going to recruit 2 folks to help you – within NOP. Hope to have people in place by summer.

Organic Transition Initiative: You heard a great update this morning. Thanks to the panelist for being here today.

Market Development: Upcoming Competitive Grant Request for Applications – Want to give an update – specific information – $300M initiative. A lot of the pieces have been announced – TOPP, NRCS did a launch. There is an upcoming competitive grant request process. There is information on the AMS website – we are looking for peer reviewers. In general, grant application periods are open 60-90 days. Funds are rewarded following peer review and internal processes. The pinpointed markets are grain, feed, legumes, other rotational crops, dairy markets, and dairy. Program is planning to be regionally and crop specific. Targeted to key markets to ensure meaningful impacts. Investments will be outside of the cost share program, because we do not want to duplicate efforts.

We do continue to coordinate with NRCS and RMA on these initiatives and trying to figure out how to reduce the multiple avenues in reporting. Every program has different rules based on funding sources. I think those partnerships are being built, and I wanted to emphasize that.

SOE – Even though we talk about this being in the implementation period, there is a lot that we are doing now. We have seen sentencing with prison time for violators.

QUESTION & ANSWER SESSION:

Kyla Smith: In my opening, I said I was equally excited and terrified for SOE. You encouraged us to all read the rule, and certifiers still have questions. Can you speak to if and when we might see additional resources in the OILC for the rule?

Dr. Tucker: We will be putting training into the learning center. Right now, it’s scheduled for summer. Every certifier’s system is different. We have to be careful with how think about consistency. b/c some folks really scared it will have such impact on small farmers and handlers that won’t drop out. So, want to make sure folks telling us about challenges we don’t want SOE to adversely effect in search of consistency. Middle of long supply chain is where main risk lies. Not talking about local, regional – not risk area as much. Certifiers need to keep in mind what trying to go after. Will put something in learning center and ACA is doing good job of setting up sessions.

Nathaniel: Commend program on SOE – quite an undertaking. Wanted to acknowledge. It is the type of rule that its success means we do not really see anything in the news – like food safety – when it succeeds, nothing happens. I hope that is the outcome from this. Question relates to President’s Executive Order on racial justice – I am encouraged to see the Program taking on some of the Racial Equity recommendations from the Equity Commission. I found some of the first response underwhelming, but good first steps. I’m curious from the Program what you can see we can do to help you integrate some of those recommendations into your workforce or support your work at the Board level?

Dr. Tucker: Appreciate that. True change happens both at personal and systems levels. We look at actions we can take at Program level to support broader USDA and each of us needs to look at internal level. At the AMS level, our agency was ahead on racial diversity by setting up a group on this. I meet with civil rights every quarter. We do active hiring through different types of recruiting. We are bringing on diverse hires. These are core values for us as a Program. Remote work has helped us in diversity! We’ve looked at our job requirements in different ways – organic is not very diverse – we realized our job descriptions needed organic experience, closing ourselves off to sources of organic diversity. Some positions provide an opportunity to learn organic. As an exec within AMS going to trainings: I’ve become aware of things I haven’t been aware of before. I entered the world as a woman with disabilities: wondering if I got the job because I am qualified or because of sources of differences? I think everyone with sources of differences wants to feel that way. I invite the NOSB to work on this issue and invite you to look at yourselves and how you approach your world as individuals. On the panel – who got asked questions and who didn’t? For example.

Allison: Heard overwhelming support in comments for furthering recognition of organic as climate smart. Can you offer an insight for advancing that as a priority within USDA?

Dr. Tucker: That’s been an important conversation over the past couple of meetings, and I’d encourage you to keep having those conversations. You can give us a recommendation, and I think there are certain items on the Work Agenda that we keep open. A number of people have been talking about today devastating things that have happened on their farm. We do bring that back to USDA. We keep a close relationship to the team that are working on these topics. Keeping yourselves at the table, and participating in broader programs outside of the organic community.

Brian: Specific question. Last fall I brought up issue of accreditation of Texas Dept of Agriculture certification program. As I understand it was withdrawn and appealed.

Dr. Tucker: I do. Is Robert here? Yes. I want to highlight the Accreditation Division – Robert is the Director – and they oversee the certifiers. Texas Dept of Ag received a proposed suspension of their accreditation – appealed it – it was denied – upholding the suspension. This is all due process in the Regulations. TDA has requested a hearing in front of an Admin Law Judge. That is where it is now within USDA. A hearing for that is expected in early 2024.

Amy: Market Development component within TOPP. Want to highlight 2 specific needs: grain and feed need special attention and require federal licensing and oversight. Facilities going bankrupt and issuing claw backs and even though delivered grain and need to pay back due to bankruptcy laws. When approving grants want special consideration of financial wherewithal of companies. Second, crop insurance protections – so much risk in organic farming, we are almost encouraging producers to grown no-insurable crops.

Dr. Tucker: Appreciate the comments. Market development grants are focused on building that infrastructure. Coordination with RMA. I think that you folks have been engaging in Crop Insurance. I think this Board is getting more involved in the broader set of USDA. I also want to emphasize that the topic technical assistant element can also be about market savvy, development, and planning – how do you protect yourself as a farmer going into the market. I think how you navigate the economic landscape that minimizes risk is important. I think that getting that expertise to the right people is important so that the buyers and sellers know how to ask the right questions as part of that process – that can also be part of technical assistance.

Amy: Enforcement and implementation of SOE. What cross collaboration happens among our equivalency partners? How do we work with them when we do these enforcement acts?

Dr. Tucker: Equivalence for those not familiar is when we agree with another gov’t that our organic standards are equivalent (fair). The initial equivalency agreements – they were very focused on materials and practice standards. Today, we are looking at a broader control system perspective (how do they do enforcement and compliance). There are countries we do not have equivalency because they are not the same in how they do oversight (so in those countries you need to use the NOP standards to sell in the USA). If we’ve been growing as an industry we have also been growing in oversight. If other gov’t are growing in operations we are watching to see if they are also growing in oversight. We have a lot of technical conversations with other gov’ts. Very technical conversations with CA regarding supply chain audits. The EU published new regulations recently. All gov’t that we have agreements with, we need to renegotiate. We did terminate a trade arrangement with India. We found that control system was not adequate. We had an 18 month implementation process. Robert just had 4 folks in India doing audits for 4 months. Trade notices that. A few years ago, I was told that India is the wild west of organic, and I got a call a couple of weeks ago that said it’s not anymore.

Are there still challenges around the world in many countries? Yes. We now have more tools that we had before. One of the challenges we have are operations that get kicked out of the program but keep shipping products. Import certificates will put a stop to that.

Import oversight is a big part of what we do. Won’t always hear the news stories of what we do.

Carolyn: Several commentators asked us to try to accommodate farmers’ schedules and trying to have Jan virtual listening session. What would that look like?

Dr. Tucker: If the NOSB is interested in exploring that option of a listening session for farmers. There is a repeatable calendar every 6 mo. If the NOSB wanted to supplement with a winter event between Fall and Spring meeting we need to know how it would inform NOSB deliberations. Deeply appreciative to community desire to engage in process.

Compliance, Accreditation, & Certification Subcommittee (CACS) Update

Amy Bruch, Chairperson.

Nate Powell-Palm notes that Mindee and Allison are virtual on Zoom.

Amy: Welcome back. Three topics to dive into. Three additional topics before get started. Thanks committee. Had a lot of great public comments and having voicing on all sides of the equation. Thirdly, additional work agenda items: enforcement, organic and climate smart agriculture, and human capital.

Enforcement- Expand residue testing for global supply chain.

Organic and Climate Smart Ag – What & Why Organic – Goal is to summarize the infrastructure behind the program and promote advantages.

Human Capital – Supporting Transition – Determine tools and alignment strategies that support transition.

Proposal: Organic & Climate-Smart Agriculture – Organic IS climate smart

Nate Powell-Palm: This was prompted by Dr. Dimitri. Started as a letter to the secretary. Climate change and responding through agriculture is topic priority and we wanted organic contextualized for addressing concern. Administration responded with list of questions to inquire for entire rest of USDA how organic is climate smart. Given prompts to answer and that’s what we did. Not a lot of latitude to explore why organic is most climate friendly option out there. In the preparation for climate smart commodity partnership which was a funding program to different grant opportunities for projects and research, we had a deadline. Our job was to communicate to USDA why organic is climate smart. A lot of organic projects got funded through the partnership. Standing work agenda item. With this document we answered questions and program gave very quick turnaround for questions. Not the end of the game, this is an open work agenda item. You brought a lot of questions about what climate smart means to organic. We’ve answered the questions. It’s not a vehicle for giving all the information. We get more work agenda items to capture all that is relevant to organic and climate smart.

Brian: Not feeling too good about this. Think the proposal as written applies really well to about 90% certified organic operations. Reluctant and struggle with this. Several classes of org farms should not automatically qualify for organic climate smart. At least way I understand climate smart, a farming system that is positive in responding to climate change. A few that don’t think qualify is what we call deep compost vegetable production which a lot of our small scale farmers do in NE and Midwest. Compost applied at approx 10% more and used like a mulch and if done year after year, it is just an incredible input in carbon that’s not coming out in output. Another one is the hydro and container production that is very energy and plastic intensive producing high yield but not a positive balance in terms of climate. Dairy operations that import the majority of their feed that do not have the acres to apply the manure to, I do not think they will make it. Finally, the use of heavy amounts of plastic mulch in some of our berry and vegetable operations. Those throw away a lot of high-energy intensive materials every year. I believe that we really do need more life-cycle analysis on these types of systems. Almost all of the research that is done on climate-smart organic is done on soil-based, standard cash grain operations. It is not done on these specialty systems that do not really make it. I do believe that 90% of our organic farming operations are very climate smart. I do not feel comfortable with this blanket sort of recommendation that all certified organic farms automatically qualify.

I’d like to see this go back to Subcommittee. It wouldn’t take too much to fix this and make it really reflect the climate-smart status.

Amy: A question for you, Brian. I think we are very fortunate to be organic farmers. I’m just questioning when you say, “climate smart,” there isn’t one definition for that word. What is your definition so we can calibrate as a board what we’re talking about? What is your interpretation?

Brian: I struggle with that one, too. It is basically a farming system where the input, when you balance the inputs of energy and carbon and the lifecycle of the inputs in terms of the energy that is required to create them, and you balance that with the outputs of the system, including the buildup of carbon in the soil, our inputs minus our outputs need to be a balance where the outputs are bigger than the inputs. That’s the way I’m looking at it. Would love to hear some other takes on it that might change my conclusion on this.

Logan: Question – inputs and outputs, is that per season or per year? Organics is the entire system and yes strawberries or tomatoes have to be on plastic for the type of production. Is it more climate smart compared to conventional?

Brian: I think that is one of the ways this proposal could be improved, and that is that I think that almost any organic system is going to be more climate smart than its conventional counterpart. You want to use the whole system – not only looking at one short season crop – it has to be the whole rotation and whole farm. In terms of suggesting that all certified organic operations should be eligible for government climate-smart – we are not saying that they are better than the conventional counterparts. We are saying that they are climate smart.

Dilip: Clarification to Amy or someone else. This proposal is that we going to suggest organic agriculture in general is climate smart or are we talking that each or agriculture practice or management practice is climate smart and certain org management practices are climate smart. Just want to understand.

NPP: We’re proposing that the organic regulations are climate smart. We were given – turn to page 3 of proposal – when look at questions, look at cover crops, no till or till, buffers, nutrient management. How does organic interact with these very specific practices. All are baked into the standards so is organic generally climate smart – they are asking are these specific practices included? We answered specific questions about particular practices and organic is head and shoulders above conventional. If we can’t say that we have a bigger problem on our hands. We are going to dice out details, but for these practices requested we are going to say organic. It is organic versus conventional. We are up against whether organic is at the table. This doesn’t make everyone suddenly love organics, but what consider climate smart, for these practices organic has it baked in. Organic was the original climate smart solution. Our system works, we have market for it, we should be one voice. Question to Dilip – asked about particular practices and how correspond to prompts. Answer is baked into the regulations.

Carolyn: First, I want to say something to NPP. I admire and respect your desire to have no conflict. I do think there has been a history of conflict on the NOSB and in organic, and I recognize that you are trying to navigate us through what could be land minds. I do not think this Board will have a giant fallout over this proposal, but I do have some comments. In the interest of full disclosure for the new people on the Board. When we got the 17 questions, I came back with a very snarky comment of, “USDA, go ask your staff these questions.” NPP was much more diplomatic and typed out answers to each question. 1. When people read this, they aren’t going to be thinking that we are talking about the practices, they will think we are talking about anything that is USDA organic. 2. I agree with Brian. There are some cases where it just isn’t going to be true. Those are the cases I worry about. I think they have a competitive advantage in the market because they can produce at a much lower cost. I think you see this in organic dairy very clearly, and that concerns me. I also think the climate smart phrase isn’t defined yet, but there are companies that do really great at marketing based on climate smart. I do not want to add anything that is going to allow some hydro company to say that they are climate smart. I do not know if the right thing is to send it back to committee. Maybe we can make some small tweaks.

Nate Lewis: I hear you loud and clear Brian that there are likely going to be some operations that do not provide net carbon sink – which is one way to describe your concern. I am not thinking that every farm needs to be a carbon sink to be “climate smart.” The regulations have the potential to applied to every farm to be climate smart. The USDA is trying to draw a circle around everything that is climate smart and if we don’t get in the circle in time, we will miss the ship and not be included. This has been an issue for other USDA programs. We need to get on the bus early with USDA. We can go back later and carve folks out as needed. We don’t need to do that now because the standards meet what USDA is describing as Climate Smart. I want to move this proposal forward no matter how imperfect it is.

Wood: Really like Brian’s definition of what climate smart means to you, I just want to frame is bad and the question we were asked was fuzzy about something called climate smart. Responsible ag should be about storing as much carbon as possible for me, I look at page 3 and it says principles of regenerative ag. I wish this was more about organic being regenerative. So many different angles about what does regenerative or what does that mean – I get the frame I don’t like the frame. We should be singing from rooftops that organic is regenerative.

Kyla: Sitting here reflecting and landed similar to what Nate Lewis had said. I am thinking about unintended consequences and timeline. That is what I was thinking about. Is it better to move forward with the proposal and have a seat at the table, and what is the unintended consequences of that option and that version, versus sending it back to subcommittee.

Carolyn: Jenny, it seems that USDA is down the climate-smart road already – they’re not waiting for us, are they?

Jenny: They are very interested in hearing from the community. USDA proposed this work agenda item to help you tell the story of organic. There is a lot of about organic that is climate smart. I cannot advise you.

Jerry: Simple question: when we first started this I asked: “Unintended consequences – what do we want?” of this document. What I got back to that queue was helpful: “we want to be in the queue.” By and large as the organic stepchild we are not in the queue. To Brian: During our oral comments last week there were so many comments on hydroponic. I am sensitive to that. Hydroponics is part of the discussion. I saw four different references in the public comments that said hydroponics and climate smart ag do not mesh. We have a living document here, do we not?

NPP: No. This is a living work agenda item, but for these questions this is final. We did not solve climate change, shocker.

Jerry: I stayed quiet until this point because I thought I saw things coming together in a way that makes sense to me. I think that we do need to be in the queue. We aren’t in the queue. Let’s get in the queue.

Kim: This is not perfect, but I don’t know if I can answer Brian’s questions and make it perfect in this format. Or if taking it back to subcommittee and trying to redefine it. Things I wrestle with – as an industry there is a lot of work to do, but this is starting point to get us where we can go. I haven’t heard enough to say we should take it back and when bring it back up in fall we’ll be 6 months behind. We have to start somewhere. I hear you Jerry, it’s hard to make sense of it. Comfortable with us moving forward.

Amy: I am glad that this topic and work agenda item is a living one. This topic, and we have to refer to the scope. I agree with what has been said – we have to get on the bus and in the queue, but I think that we need to be the leaders. I believe that Carolyn got us onto this with a letter that she wrote to the Secretary of Ag because there were no references to organic. I think there is way more to the equation than just carbon. This is a gray area that we need to make black and white. Water is part of the scope, but needs to be part of the conversation. Equity needs to be part of the equation. So much we aren’t talking about because we are so focused on carbon. Organic sector needs to be the leader in this area. I do have 1 question: Based on oral comments, there was also a correction that in this current document, we should probably talk about the need for changes.

Franklin: I’m of the view that all that is done in organic agriculture we are more qualified than most to be in this category. We don’t have to be perfect to be in this category. If we wait, then may never get included.

Nate Powell-Palm (NPP): Hear, hear. Thank you. We heard from the ever-articulate Mike Dill that we have some absolutes that need to be adjusted “synthetic nitrogen” instead of “synthetic fertilizers” and then “most” instead of “all.”

Alison: Along the lines of synthetic nitrogen fertilizer. What USDA is putting forward is what is climate smarter and synthetic nitrogen fertilizer accounts for 2.4 percent of global greenhouse gas emissions. When dominate practices rely on greenhouse intensive inputs and one of reasons focus on healthy soil is b/c it avoid s talking about greenhouse gas effect of inputs. Appreciate range of climate benefits that might benefit from that type of production. We have a lot to stand on and shouldn’t let the dream of the perfect get in the way of touting organics benefits across the board.

Mindee: This is different than the context the NOSB usually engages in. We usually look at the minutiae. This is the greater concern for the earth: we can communicate our greater care to the USDA. In this context “organic” — it’s a real opportunity to voice the very specific sound support we have for climate change. This document provides context and information for those that need greater understanding of the work organic does that benefits the environment. I want our voice to be expressed clearly and am proud to support this document.

Brian: Thanks so much. What I’m hearing is that we do not want the perfect to be the enemy of the good. I’m hearing from everyone that maybe in the scientific literature, you have to be really careful about what you say, but in communications that are not all that parsed and rigorous, it is not the same thing. I think that this document makes really strong arguments in favor of organic, and I have been convinced that the goal that we can achieve is not as important as some of the things that I brought up. I think that we can say that we put this thing through the ringer. I think that 90% of the arguments in the document are forceful.

Jerry: I have heard in this room today back and forth two things – organic is THE climate smart solution, or it’s A/AN – which is it?

NPP: I’m an organic guy all of the way, so it is THE climate smart solution.

Dilip: I haven’t seen a clear definition of climate smart. I might be wrong – if we don’t have one, whose job is it to put forth a clear definition?

NPP: Right there with you. Brian did you want to put in motion to send back to subcommittee?

Brian: No.

Amy: Are we ready to vote? I’ll read the motion for the record then.

Motion to accept the proposal on organic as Climate Smart Agriculture.

Subcommittee Proposal:

While all certified organic production is climate-smart, not all “climate-smart” production is certified organic. Therefore, this proposal aims to articulate why, if an agriculture producer is certified organic, they should be automatically considered climate-smart and made eligible off all climate-smart funding, buying, and other programmatic opportunities administered by the USDA.

Vote:

Yes: Alison, Brian, Nate Lewis, Dulip, Kyla, Amy, Jerry, Mindee, Kim, Franklin, Logan, NPP

No: 0

Abstain: 2 (Wood, Carolyn)

Recuse: 0

Absent: 1 (Javier Zamora)Motion passes.

Discussion Document: Organic & Climate-Smart Agriculture – Climate Induced Farming Risk & Crop Insurance

The reality of organic crop insurance: Not meeting organic farmer needs and not meeting actuarial mandate.

Amy: This is important for the community. We had a research-forward approach. We are looking to build on this to make recommendations for a future proposal.

Carolyn: A few background things to say. Partly, this is part of a larger research project that I am working on to improve farm programs for organic farmers. Many people on the Board have been interviewed by my team of researchers who have been doing a good job of tracking people down and asking lots of questions.

I am going to take us back through time a bit. There is a reason for this. Partly looking at how farm programs have evolved over time is important when looking at them going forward.

Crop insurance was developed in 1938. Farmers didn’t really like it. Slow adoption over time. 1980 Farm Bill said that insurance premiums would be subsidized by the USDA. That created private sector agents. 1984 there became a lot of requirements for insurance. 2000 premium subsidies increased. Almost all of our farm programs at this time are couched as a form of risk mitigation.

In 1994 and 1995 big input in acreage. So, discussion about crop insurance and risk management agency and b/c organic so small it’s hard to understand the extent of usage of crop insurance. RMA records kind of weird things, including share of acres insured by crop insurance. Have almost all conventional farmland being insured. And then there’s this part of farm bill that requires crop ins be actuarially fair. The thing that’s striking is loss ratios. For organic crops (except apples) loss ratios are much higher and have questions why risk management agency has these set up as two separate risk pools. I think when you think about moving ahead and making crop insurance work, you have to deal with the reality that from an economic perspective, it doesn’t seem to pay, because there is more money going out than coming in.

Belasco survey – tried to understand why a lot of organic farmers aren’t using crop insurance. Reported the percent of their farmers that use crop insurance. From the people they talked to, the field crops were using CI at higher rates than other producers. They could have some sample bias, and that’s why the #s are low, but overall you see fairly low adoption levels. What my research is trying to do is to look at state and local information to compare commodity findings for the adoption of crop insurance. As far as the surveys we have, they really cannot say whether or not it is likely that an organic farmer will use crop insurance.

The reasons that farmers give for not using crop insurance – the public comments reflected – it’s very expensive, farmer isn’t familiar with it, farmers do not want or need it. This comes from USDA production surveys through organic data initiative.

Have a couple of thoughts: what I’ve learned is that we have a couple of groups of producers: those who use crop insurance and they have very strong ideas about how to make it work better. The diversified operations are in a different pool and find it doesn’t work for them. The usage rates are declining over time. Problematic. A group of people think crop insurance isn’t suitable for them. And then dairy producers need better support as well and their needs are different from diversified needs.

I have a couple of other thoughts to launch our discussion. I do have a lot of research in progress with now and will be able to share some of that soon. The other idea I had that could be helpful would be to ask the Secretary of Ag to have USDA create a farm policy task force that has representatives from all program agencies to understand how to improve the program – economist who think about policy and how to design farm policy, and also program implementers – risk management agency or NRCS. I would like to see a Task Force that worked really hard for a year and then wrote a report, and then we could read it and see what they had to say.

Kyla: If we were to put that into a pie chart, what would it look like?

Carolyn: I think that maybe half of the people do not need it or want it.

Amy: Is it because coverage is not adequate. Do we have the rest of the story with reasons in the survey?

Carolyn: No, because I think that when USDA does a survey, there are just checks, and people check it and there isn’t room to add more information. I have not looked at the survey instrument, which is on the USDA website and I can later, but usually they give you 4 reasons and you just pick one of those reasons.

Logan: Don’t need or don’t want could?

Amy: From my perspective, the same interactions and 2 different types of scenarios. We’re recruiting transitioning producers and have a lot of figurative risks: market instability, uncertainty, do not have transparency with markets like conventional. With transitional they are looking at 36 months so real uncertain. Markets where handlers are going bankrupt. As organic producers should have coverage we can count on or at least supplement the gap and I realize crop insurance can be complicated but think all familiar with insurance (health, car, etc.) when have an asset worth X dollars, when conventional house gets adequate coverage. If organic, get discount that is not associated with own production history. There is a real big disadvantage when have production experience versus someone with zero experience and wants to be conventional. Right now focusing on crop insurance and have to make it function.

Logan: You see it isn’t working for the farmer, and it’s not working for the gov’t, either. It’s not working for anyone. That’s what I am comprehending; does that seem right?

Carolyn: Yes. That’s why I question if they have to be in separate risk pools. Why can’t they be in the same? There aren’t that many organic farmers.

NPP: A lot of it boils down to that data set for organic is somewhat skewed. When look at who is organic it has been folks on marginal land at risk of going bankrupt. Not those that have best yields. As organic grows, professional farmers, will be more data to support less of a risk.

Nate Lewis: Thinking back on my advocacy days and bringing farmers to meet with RMA in DC. We were able to get incremental change from RMA and explained things very clearly. Those were successful because we heard from people what the specific issues were and we got them in the room. I think we have a unique opportunity to identify all sort of risks for the Secretary. If we can create a list of all sorts of issues for organic farmers… I do not particularly want to do RMA’s job for them here, but I was also compelled by Roland’s comment this morning that risk management for a small operation in GA might look like row cover. Different ideas of risk management within the scope and scale of an operation. Might be part of how we comment to the Secretary on how to mitigate risk based on the scope and scale of the operation. Might be a framework within which we might be able to frame the conversation and turn it into productive output that USDA is going to listen to.

NPP: Want to elevate one thing you said from experience working on farm bill? Did you have any info on contract price addendum?

Nate: Many crops are contracted for so many aren’t looking for price on Chicago board and folks are reluctant to share contract prices b/c private business dealings. It was about getting the right people in the room and getting them all of the right information so that they couldn’t go back and say “actuarily sound,” which is what they do.

NPP: Both of our calls with RMA were productive and their inclination is how to help organics do better. The contract price addendum is unique to organic. Do some research if don’t know about it. One thing that b/c of work like this document RMA is able to make products that are good with tangible impacts to communities.

Amy: One thing to add about contract price addendum – not only for organic, but for transition, as well. Provides extreme benefit for our community. Grateful for the list that our commenters provided to us. Detailed ways that we can look to improve things. Need to aggregate voices and look at multiple methods of risk management.

Brian: Spoke last week with insurance agent at a meeting. Really surprised that in whole farm program they said CSAs could not be covered, because record keeping requirements do not fit with CSA model. That’s a barrier that could be overcome.

NPP: That’s one good form to fix that problem.

Dilip: One other point you mentioned Carolyn is higher subsidies for conventional. Is there a big difference for organic? Higher subsidies for conventional farmers, any difference in subsidies for organic, or are they applicable to the same subsidies. And the second was it’s too expensive b/c they have less acreage?

Amy: I can speak to this in my area, and this relates to coverage, subsidies, and your history. This was an example that one of the public commenters mentioned. It seems like, in my general growing area that is traditional for corn and soybeans, there is a discount factor that is provided to transition producers – 65% – lower base-line – I am starting with less coverage even though I do have experience, because my conventional experience does not relate at all to my transition. The T yields that set the baseline can be aspirational to some, and that’s where you’re getting high ratio payouts that do not make sense for RMA. In my area, the base-level yields that are assigned are incredibly depressed from what I can produce. I am one of those members that purchase crop insurance, but if I have an event, I do not really have the coverage that makes a difference. It’s catastrophic insurance, at best. There is a slight scale difference on the subsidies. One of the survey questions asked for the cost of it – with TOGA, it provides us with a discount on insurance – I am not finding that the cost is the issue, it’s the price that I’m getting – I’m not getting anything for the dollars that I’m spending. It’s interpretation of the words. If you’re not getting adequate coverage, then it’s definitely an expensive product.

Logan: Do you expect to use crop insurance. Is there going to be a use of it? When you’re saying it isn’t justifying the expense, how often do farmers normally see that payout?

Amy: Matter of the weather. Drought isn’t a peril I have to face compared to a lot of the country. My only risk factor with insurance is hail, and the extent of damage on my crop. If I get 30% crop damage I don’t get coverage because I am over-yielding If I was a conventional farmer my yield history would provide me an insurance payment because I would have impacted my safety net.

Logan: With the historical yields, as I was learning with some of the commenters, it has to be on that field or that farm year after year, so that doesn’t fit for organic. I think this needs to be tailored to organic. That will take a decade to get sufficient information or data.

Amy: positive change that occurred. If transition in particular county, you can move over your yield history. New yield history can feed into 4 numbers of what replacing. Clock starts over when organic so real challenge building yield history with crop rotation.

Wood: Totally off topic – Do you find that there is some built-in resilience to your organic acreage versus conventional? How does that factor in?

Amy: Yes, I do believe we have a higher level of resiliency, especially when it comes to drought. In terms of hail, that is nondiscriminatory issue – impacts everyone the same. Tools to recover are different. Wind is a big factor. The resiliency of the nutritional levels in our crops helps with wind issues.

Nate Lewis: regardless of the producer’s ability to self-insure there is often financial reality of not having choice of not getting crop insurance and working to make it more functional product, it is a requirement for a lot of conventional financing.

Amy: There is one other topic I want to discuss – diversity. There were quite a lot of comments on it. I think it needs to be defined and interpreted. I want to have additional diversity on my farm. I try to plant crops that have insurable attributes. I have one legume that is insurable, but the others that I plant are not insurable. Hand-in-hand we have to have RMA in a partner in this. What is normal in terms of crop rotation for a conventional producer is different than organic producers. Crops that make sense, we need to be able to have insurance for those. There is currently a process for this – called a written agreement – takes three years usually. They generally say that they have not had a lot of requests in that category and therefore they are not offering coverage. I think diversity could increase, but I think it’s going to take not only markets, but also crop insurance on things that make sense.

NPP: On written agreements seems opportunity for university or other folks – start throwing crops on farms to get actuarial data. I have to do written agreement on flax but no one else grows it so I have to do a written agreement. What crops could we grow in a county and get data and through universities or more strategic planting.

Amy: 100%. I think this is a big community effort. Complicated issue. I think we can move the needle. We have seen some changes that are very positive that we have highlighted here. We need a list of additional items that would provide similar type coverage when we are organic producers.

Carolyn: What do people think about a USDA task force to put some of their highly specialized knowledge to the broader topic of farm programs for organic farmers.

Amy: I love Task Forces – I think they are great. We need functional people on the team. We need insurance adjusters that visit our fields and may not have the knowledge on organic production, and agents, as well.

Carolyn: One of my personal pet peeves is that I understand how farm programs have evolved over time, but it seems that maybe organic farmers need something different. I think maybe organic farmers need something different rather than trying to tweak these programs that don’t really take care of what is needed.

Kyla: Right now the ACA has a working group about assessing resources for gov’t programs to help producers better utilize those programs. Is that a similar idea as this task force? We could see what the deliverables are from working group. Some things being discussed are: Universal OSP, how to streamline resources, etc. Maybe we could start there and pursue this other idea if it does not give us what we are looking for.

NPP: This is discussion document so more of it coming.

Amy: Thank you, Carolyn, for leading this important topic. Looking forward to continuing the conversation.

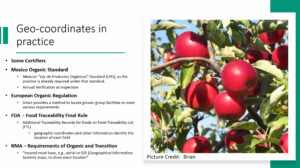

Discussion Document: Oversight Improvement to deter fraud: Consistent Location Identification

Challenge: The location of certified organic operations, including fields is inconsistently recorded and managed across certifiers. This challenges the industry, leading to a gap in certifiers’ ability to accurately cross- check the operations and fields they certify with other certifiers. Furthermore, some certifiers cannot conduct independent verification or unannounced inspections of fields because they don’t have mapping capabilities of all field locations.

Solution: Certifiers located both domestically and internationally can seamlessly harmonize the data intake of their clients when producers request to certify new fields for organic certification. By requesting the geolocation of certified operations , certifiers will be able to receive consistent data that is easily managed while also allowing the inspectors to confirm the accuracy of the data during the inspection and use it as a cross-check.

Amy: Thanks Board for farm pictures for presentation. This document is result of collaborative effort of subcommittee and chair. Slides organize the discussion document. This topic is relating to consistent location information. For certified operations the challenge is more consistent location identification for all certified operations, domestically and internationally to report GPS coordinates was an example. Buildng on basic conditions in fall to record certified acres on organic certificates. Building on that to actually know where fields are located. Based on consistency aspect and recommending that certifiers deploying same approach and inspectors can spend more time fighting fraud than finding the farm.

There were some certifier comments that mentioned that it is a low-burden ask, as it is a one-time collection. Through public comments, we wanted to provide some clarity. We are not requiring those that do not use technology to use it. We are not requiring annually where you plan each crop. We are not indicating that this information be public facing; just for certifiers to use. There was also confusion around field and parcel and nomenclature around that.

We had great participation in public comments – 7 certifiers – 1 inspector and 1 inspector group supported – several farms, including one from the plain community, supported. There were 3 commenters that listed limited support, but I hope that clarity that we provided would garner more support from those groups.

In general – how are we going to accomplish this? Great solutions and no tech solutions discussed. Trying to get a very similar language to manage these cross-checks. FSA and RMA use similar systems however not all producers are doing those farm programs. Looking for system that will work domestically and internationally.

One thing to highlight, and public comments provided some of this data of the geo coordinates in practice. We learned that the Mexican organic standard requires this. Some aspects of grower groups within the EU community have this as a requirement. FDA and new food traceability rule – some crops and products will have further scrutiny on the traceability. RMA requirement (see slide above).

Will turn it over to the Board for discussion. We have 2 recommendations in this document – one about consistency and how we are communicating, and second about land affidavits. So you have the complete tracking history from when a farm comes on line and if that farm changes hands. That whole history will be available.

CACS has two recommendations:

- Consistency amongst all accredited certifiers to use a universal system, the GPS, to obtain specific location data information of all certified operations.

- Previous land affidavits include and are reconciled with GPS location information, which is essential for both domestic and international.

NPP: Going through a couple of these things in context of public comments. In my head this is a big beautiful nothing burger and I’m so surprised how you grillers can make something out of nothing. I appreciate all groups that represent farmers. If I were not in organic community, it would sound like you didn’t have control over organic system at all. Just thinking about – call us folks if you have that fixable of a question and it took almost 2 days of comments to talk to member of plains community that field means something different than plain. Hearing from plain community it was a very quick fix. We encourage you to contact us when one word correction. Trying to describe a word applicable to unit of land is going to be unique. We need your input on right word or set of terms. We want to try to figure out word that captures a legal descriptor that would live with the property until legally subdivide it. Certifiers that have a question and want to call each other, you basically have to talk in pictures. There’s not a good vernacular among certifiers. That’s the point of this. Explain to me how we can write better because these things in my head or so simple. This is in no way a public facing piece of data. How can ewe make that more clear, because I thought that was clear in the document?

In talking about facilitating unannounced inspections or cross-checking – how do certifiers talk to each other more effectively to bust fraud – with cross-checks, we are going to have a common language to try to figure out what fields are getting double certified, what fields are coming back in one year after being sprayed. That goes beyond legal descriptions or hand-drawn maps. When representing stakeholders – and I say this with all due respect – understanding what the ground truthing comments are…we had a comment that said, “Doesn’t every field have an address?” No. Houses have addresses. We are trying to set a common denominator on how to talk about this. I was surprised at the confusion regarding what we were talking about. It seemed like there were a lot of opinions in the comments that we got that could have been done away with if we’d provided more background information – that’s on us.

If I’m an inspector, most likely going to have to ask operator where the field is. No consistent way for certifier to locate the field. It allows us a backstop so not being lead around by producer not following the rules.

Logan: Funny comment as far as the terminology and how it can differ across growing regions. In most of the world, when you say “plow,” that is to like “bottom plow,” but in the SE we sometimes think that means “cultivate.” I don’t know how that got to be that way, but sometimes we indicate that we are plowing our carrots, and people are like, “Why in the world would you do that?” I can understand how different language can be from one place to another.

NPP: We try to teach organic inspectors how to get a rip on colloquialisms. Tricky.

Amy: I was going to add with that – we have that challenge a little bit here. Listening to oral comments, there was one certifier that said that GPS is the language oversees. I thought that was interesting. The US space program are the ones that uphold the GPS systems. That is a system that can be understood internationally. I think that solving it internationally might be easier than solving it nationally.